Method for peripheral contacting in ceramic components

A technology of structural elements and electrical contact, applied in the direction of material analysis, measuring devices, instruments, etc. by electromagnetic means, it can solve the problems of short circuit of each contact, high sensitivity to mechanical load, difficult circuit and electrical connection, etc., reaching high temperature The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

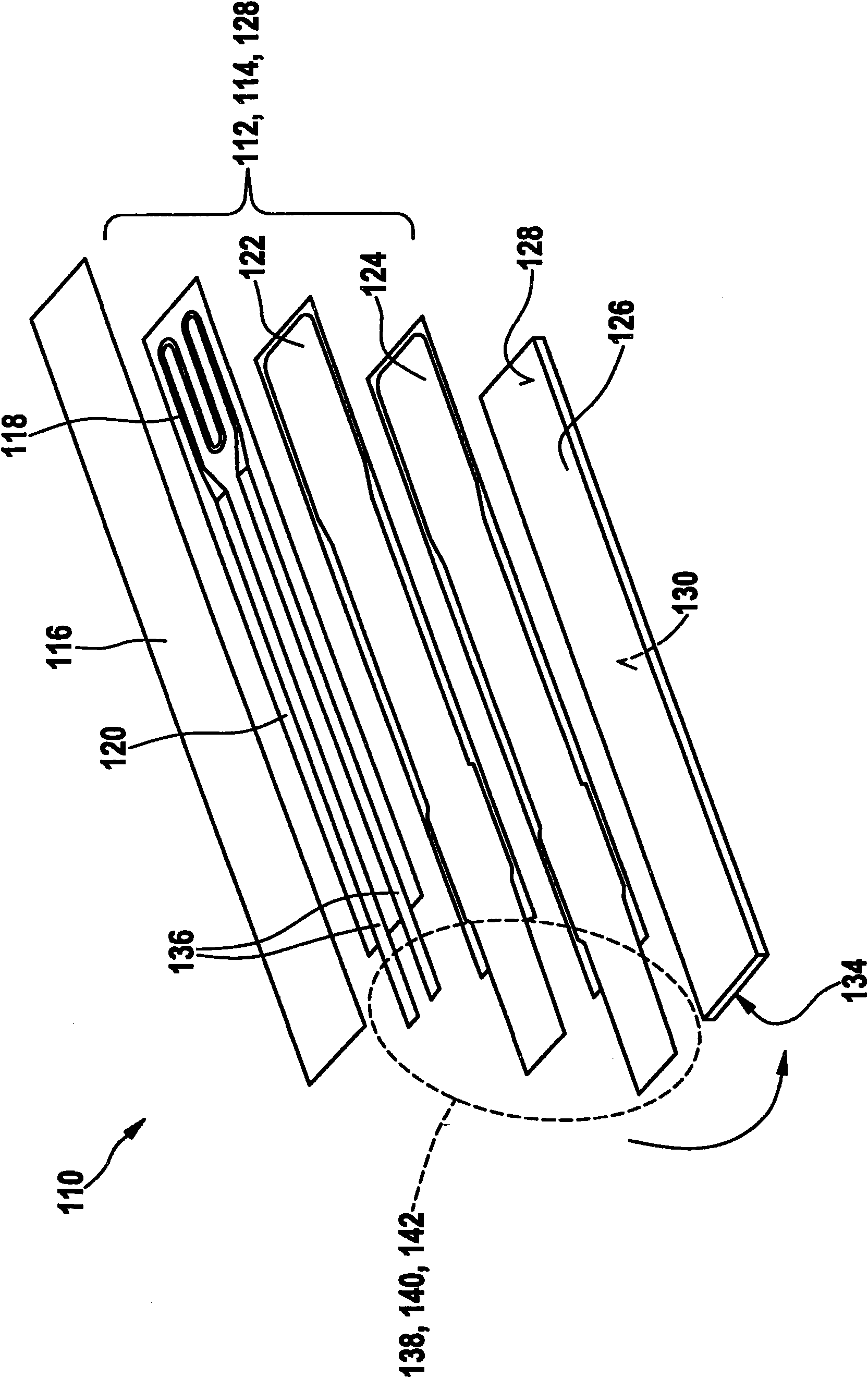

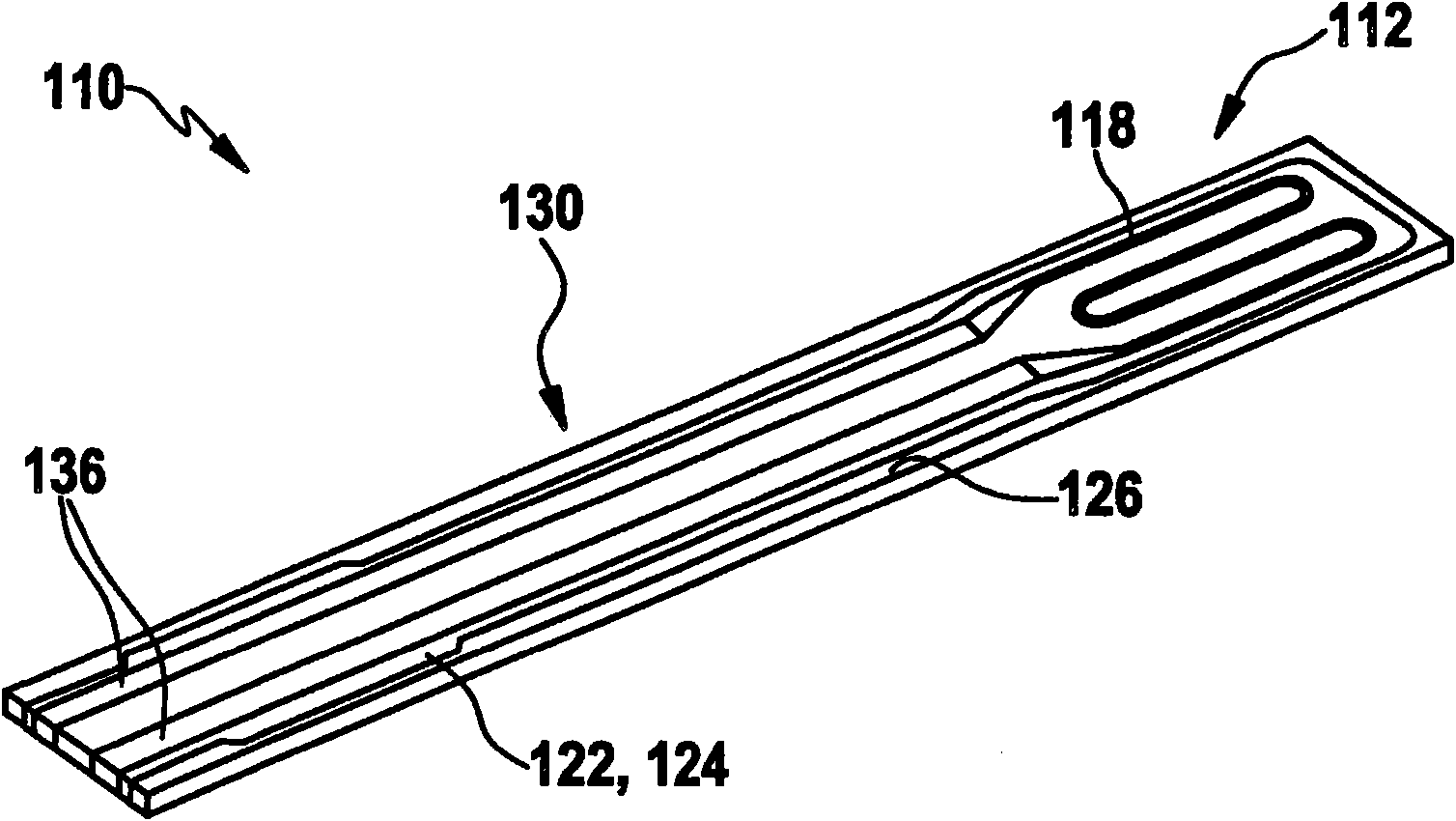

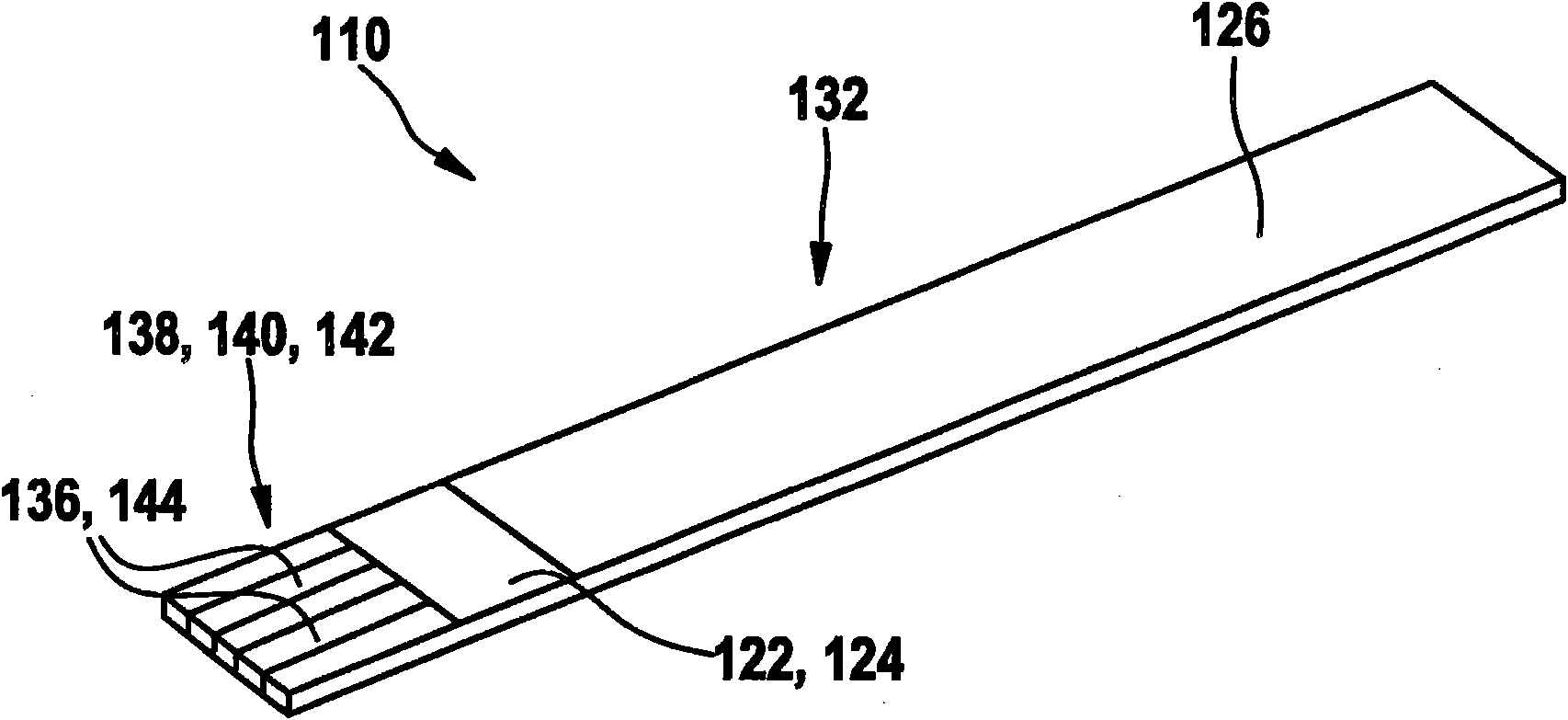

[0026] With the help of Figures 1 to 4 The proposed method is explained by way of example using a ceramic sensor element 110 , wherein only the method steps for encapsulating electrical contacting of the heating element 112 are shown. The method steps shown can thus be followed by further method steps, in particular the formation of one or more sensor units which are usually connected to one or more solid electrolytes and two or more Electrodes in contact with the solid electrolyte. Thus, in Figures 2 to 4 The products shown in are typically only intermediate products in the process of manufacturing the ceramic sensor element 110 . In this case, the illustrated encapsulating electrical contacting method can be repeated in the further method steps and / or “conventional” contacting technology, in particular through-hole electrical contacting, can be used.

[0027] exist figure 1 A layer sequence of the ceramic sensor element is shown in , by means of which the method steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com