Multi-position base plate delaminating monitor and using method thereof

A monitoring instrument and layer separation technology, which is applied to instruments, measuring devices, mechanical devices, etc., can solve the problems of few measuring points, unsuitable monitoring floor, no coal seam floor separation monitoring, etc., to prevent accidents and reduce readings. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

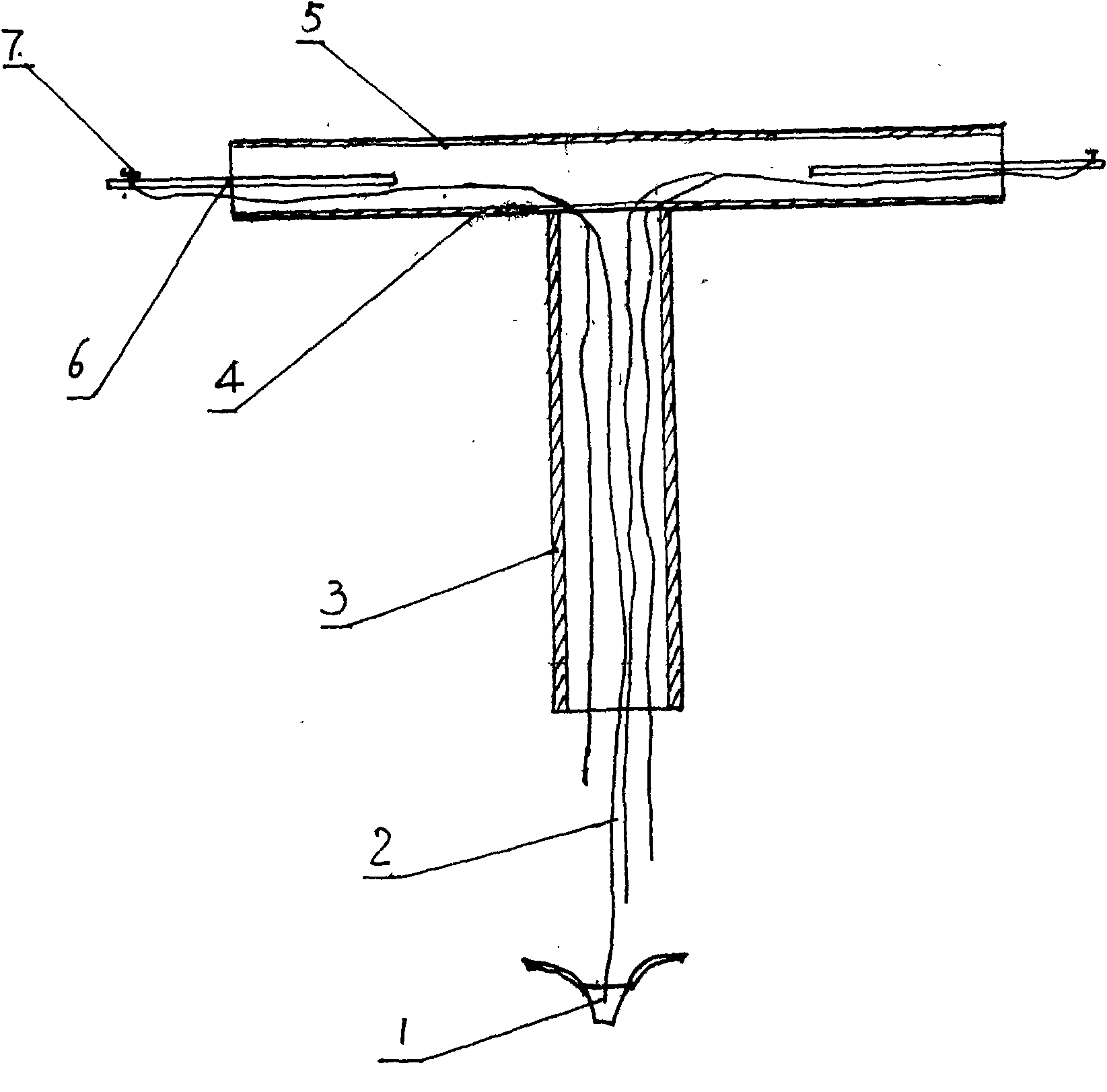

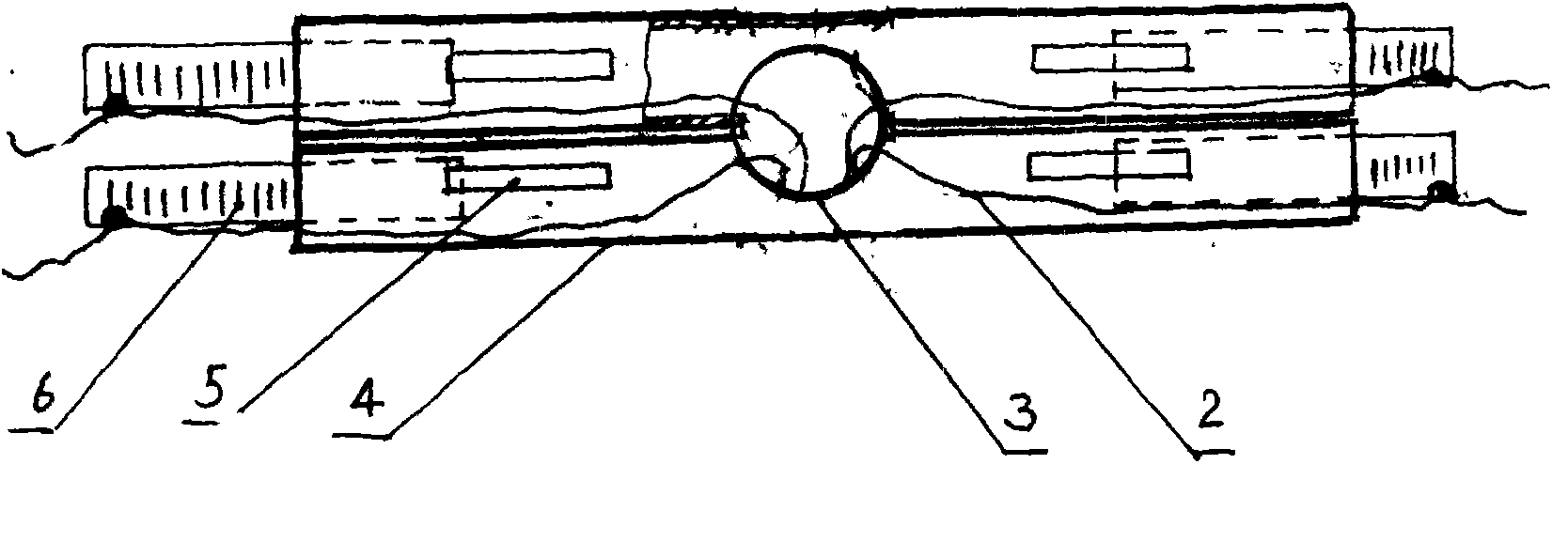

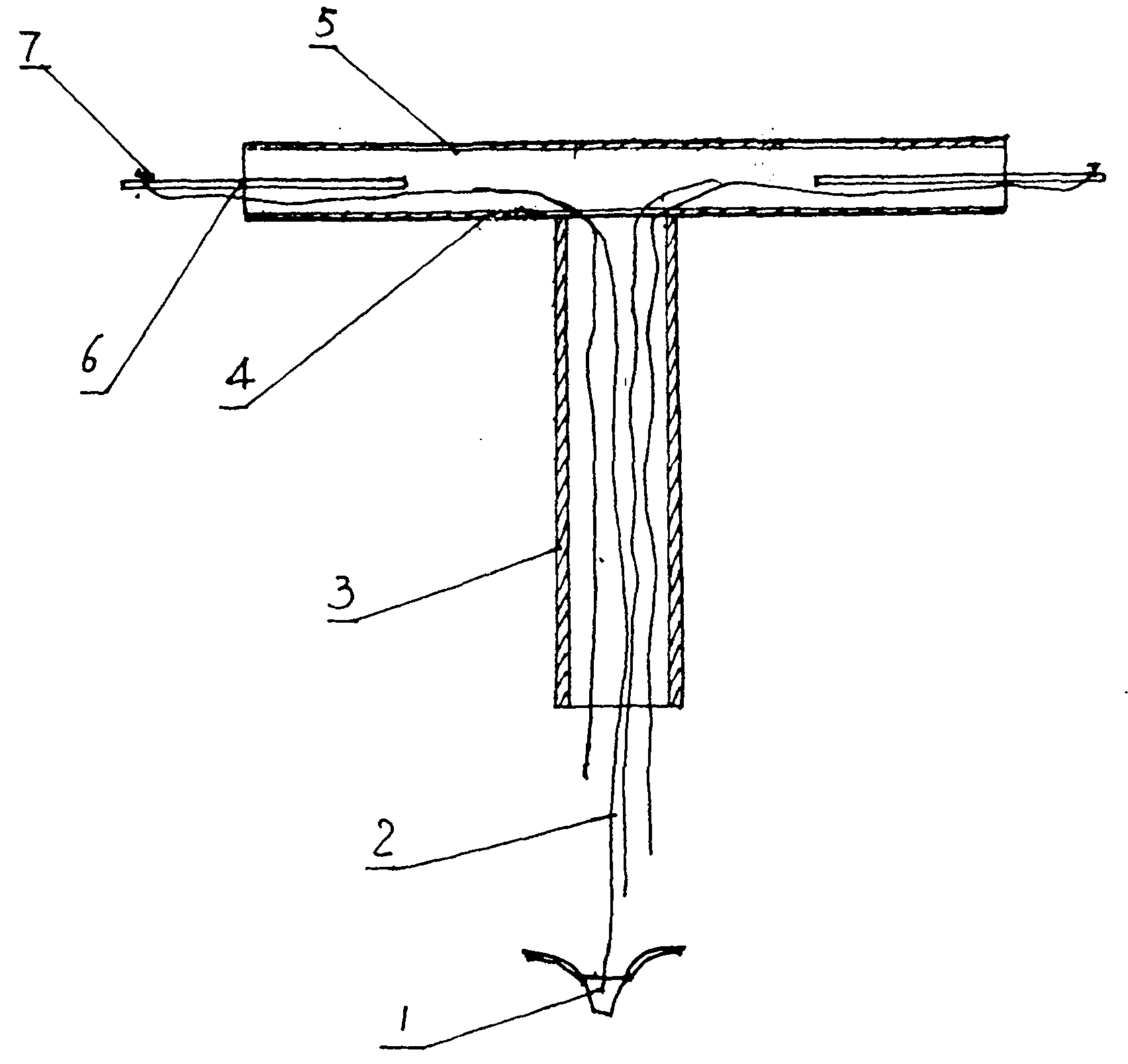

[0023] Referring to the accompanying drawings, the technical solutions of the embodiments of the present invention will be further described by taking four measuring points as examples.

[0024] Such as figure 1 with figure 2 As shown, the monitoring instrument of the embodiment of the present invention is mainly composed of a base point anchor head 1 , a stay rope 2 , a base casing 3 and a measuring ruler 6 . Connect four horizontal extension tubes 4 on the top of the base casing 3, each extension tube 4 is provided with an upward observation slot 5, and a measuring ruler 6 is installed in the extension tube 4, and the measuring ruler 6 The maximum measuring range is 150mm; there are 15 large grids, and each large grid is 10mm; each large grid is divided into 5 small grids, and each small grid is 2mm. Can see measuring ruler 6 readings from observation seam 5, and each measuring ruler 6 is all connected respective anchor head 1 by stay rope 2, and each stay rope 2 is movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com