Method for improving oxygen utilization rate of supercritical water oxidation system

An oxidation system and supercritical water technology, applied in the direction of oxidation water/sewage treatment, etc., can solve the problems of high oxygen cost and low utilization rate, and achieve the effects of improving economy, reducing the peroxygen coefficient, and improving oxygen utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

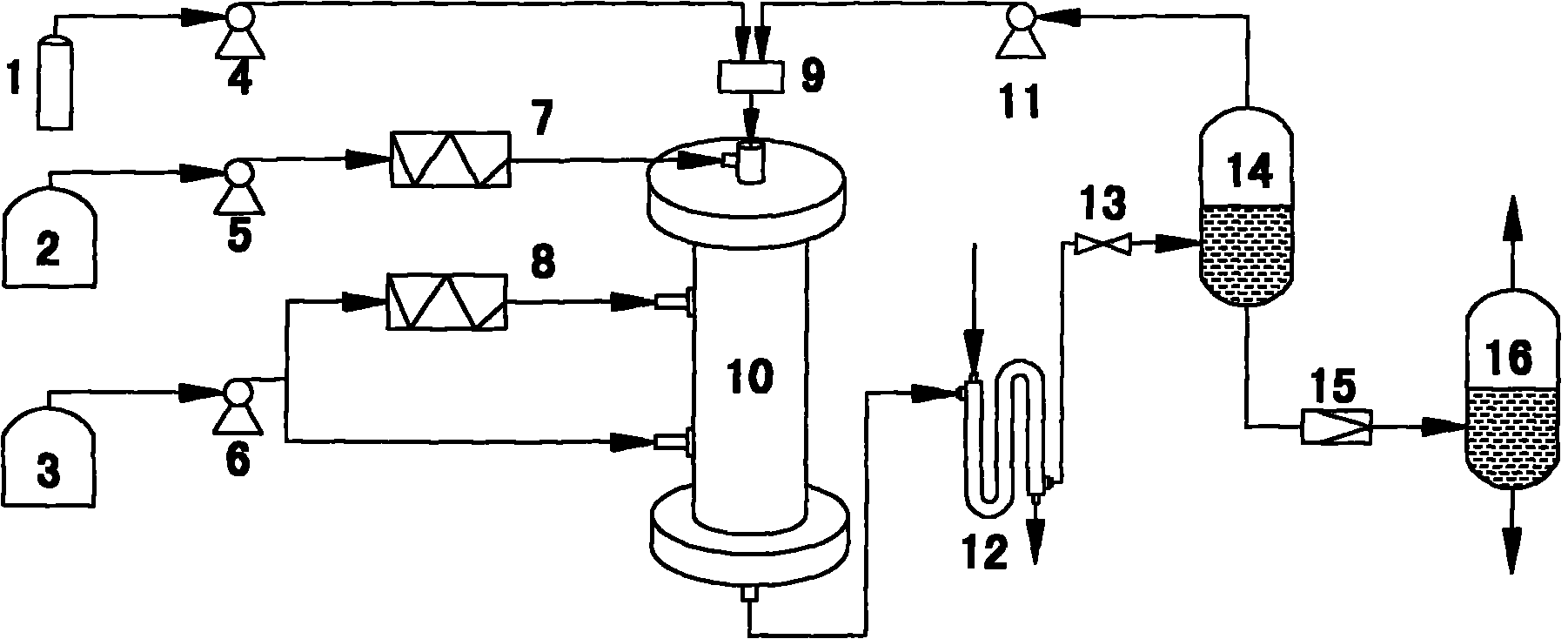

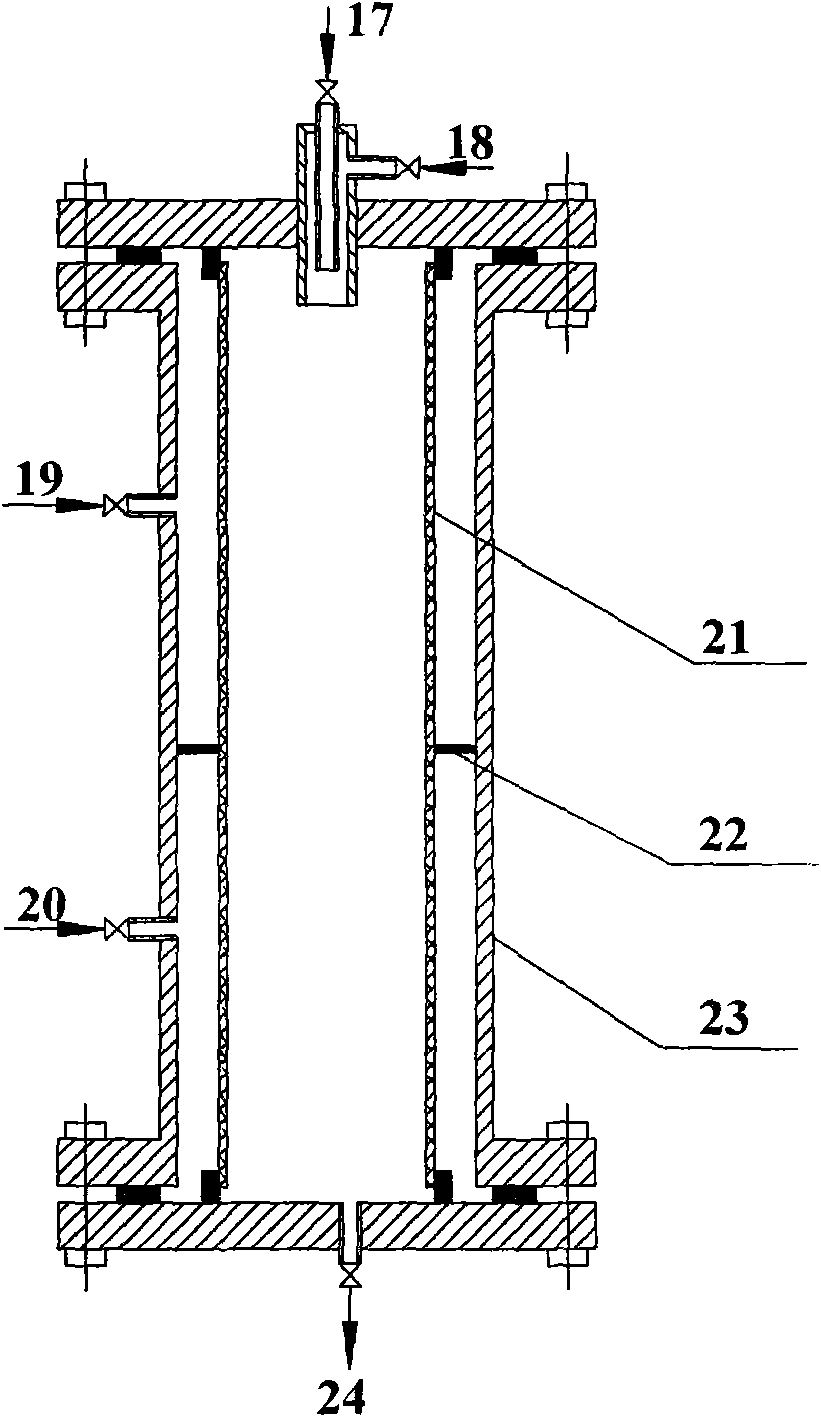

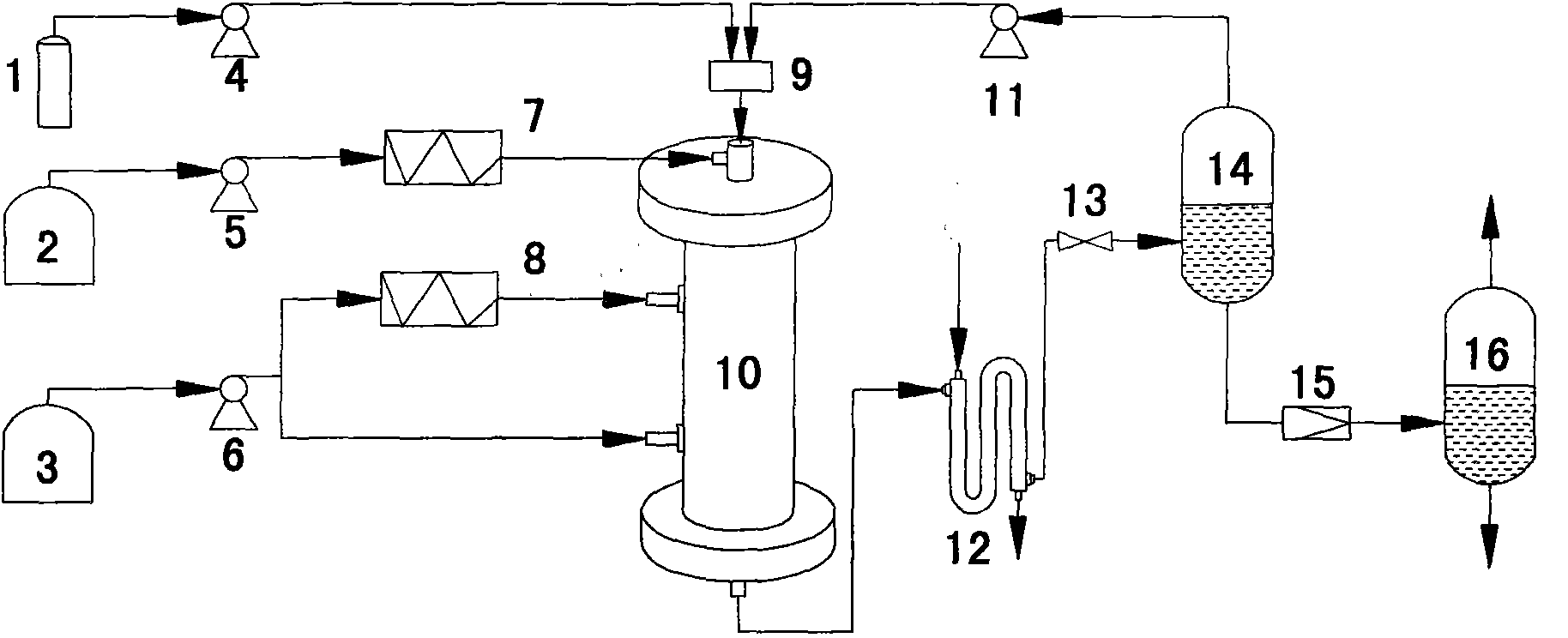

[0022] The present invention will be further described below in conjunction with the accompanying drawings and a specific embodiment given by the inventor.

[0023] The organic waste liquid with a concentration of 8wt% in the waste liquid storage tank 2 is boosted to 25 MPa by the waste liquid booster pump 5, and heated to 400° C. injection. The oxygen in the oxygen tank 1 is pressurized to 25 MPa by the oxygen booster pump 4, and is directly injected from the oxygen inlet 17 on the upper part of the evaporating wall reactor 10 without preheating with an oxygen demand twice that of the complete oxidation of organic matter. In the upper part of the evaporation wall reactor 10, oxygen and organic matter are mixed and undergo supercritical water oxidation reaction. The evaporated water in the pure water storage tank 3 is boosted to 25.1 MPa by the evaporated water increasing pump 6 at a flow rate three times the sum of the mass flow rate of the organic waste liquid and oxygen, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com