Device for conveying material by a horizontal impeller feeder

A technology of impeller feeder and impeller, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of limitation and small conveying intensity, and achieve the effect of improving the ratio and reducing the pulse effect by half

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

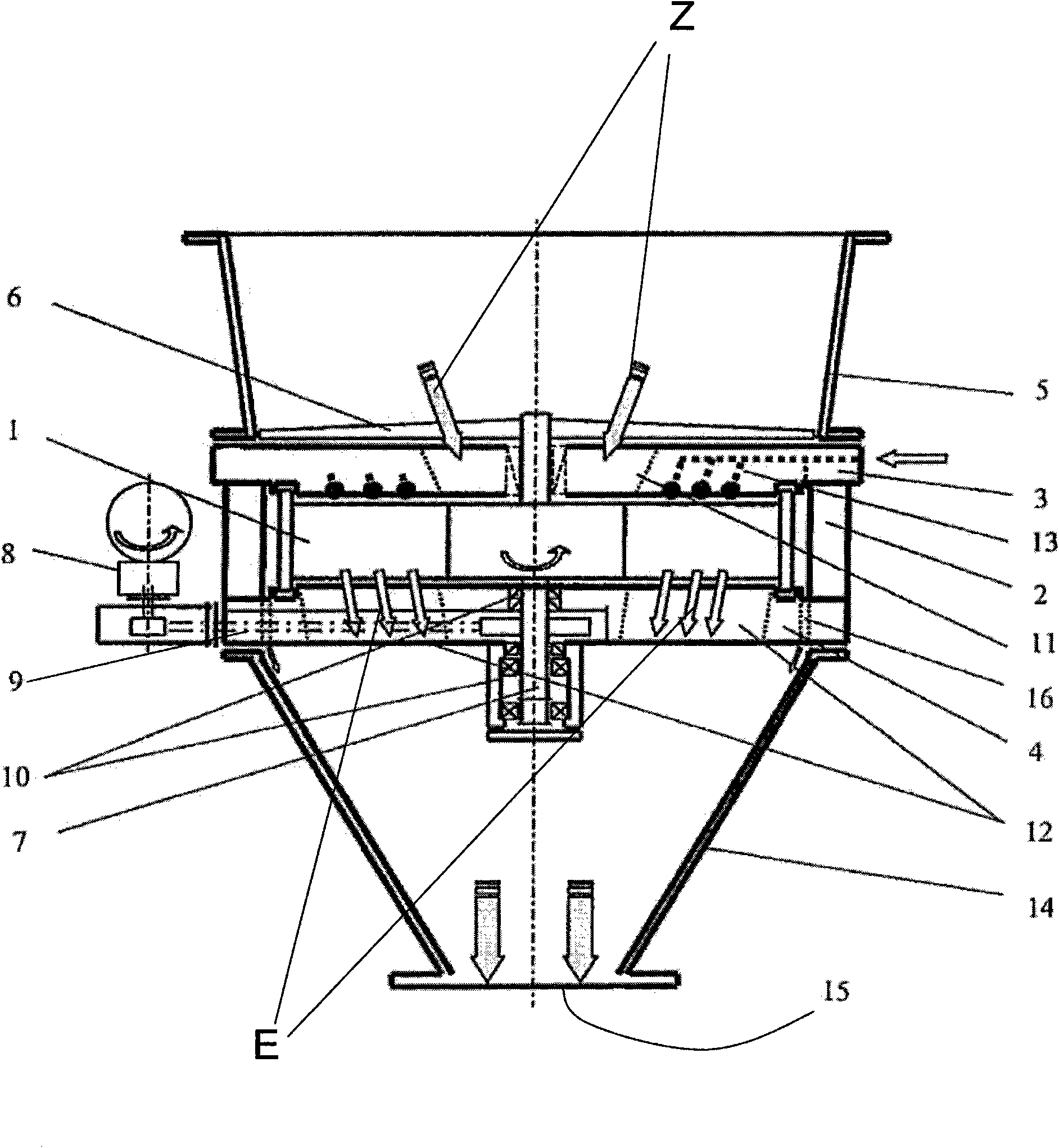

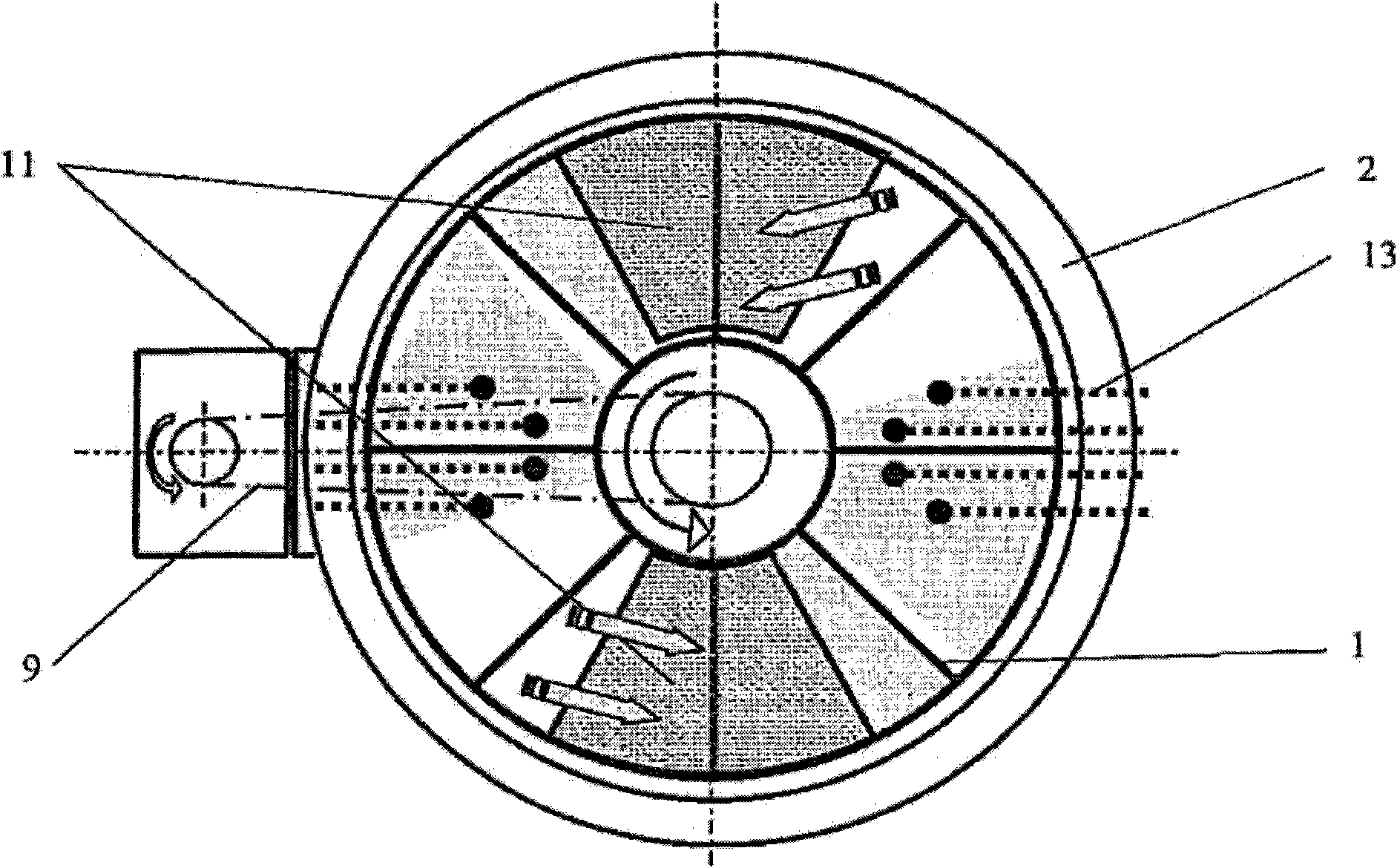

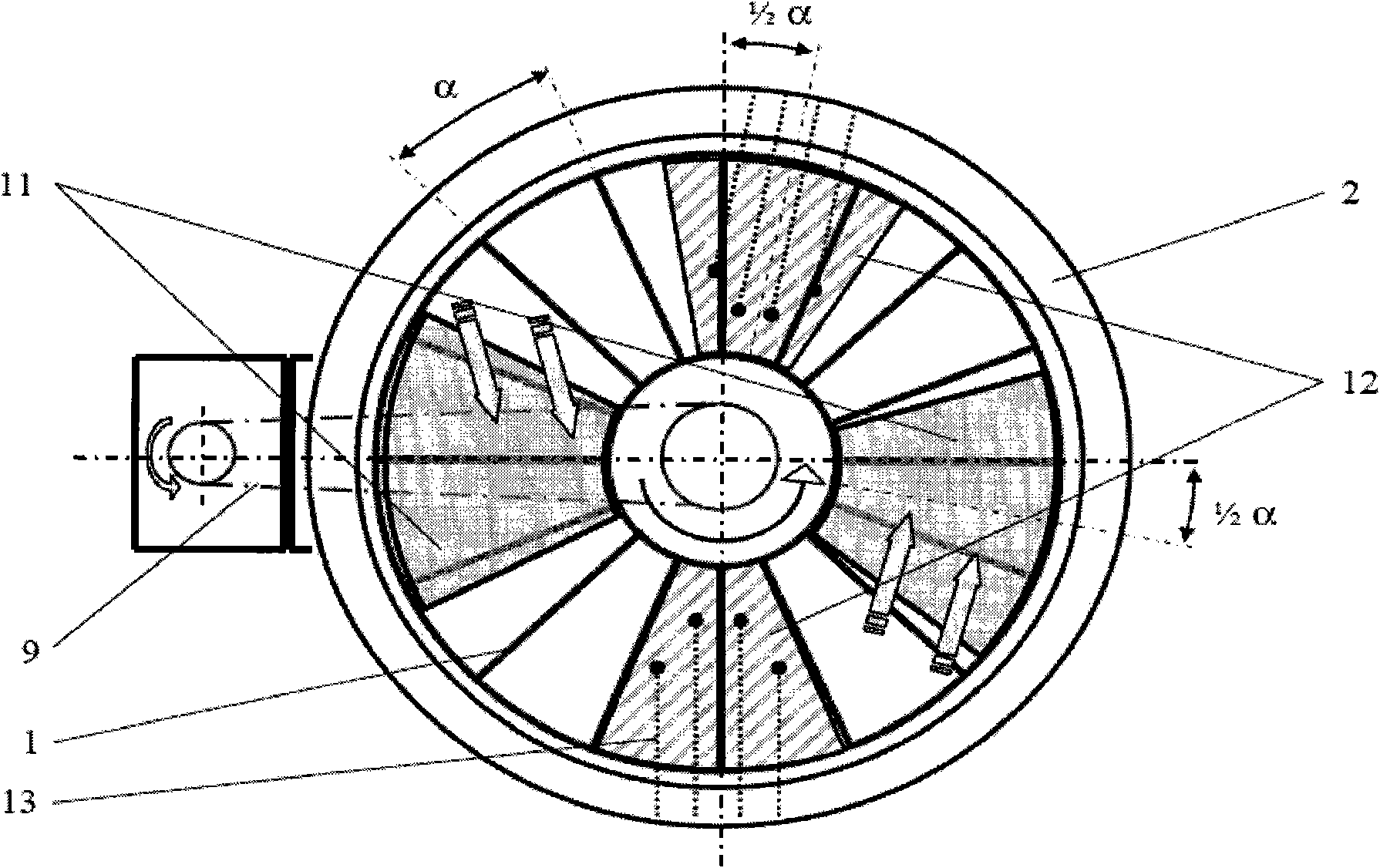

[0047] figure 1 and figure 2A preferred embodiment of a horizontal impeller feeder according to the invention is shown, which is integrated in a device for conveying material, in particular conveying and / or distributing loose material, which is shown in the figure are only partially shown. As seen in the figure, the horizontal impeller feeder has an impeller 1, which is arranged in the impeller housing 2, which is rotatable around a vertical rotation axis, wherein the material to be conveyed by the horizontal impeller feeder is fed from above the impeller housing as The arrow indicated by "Z" is directed towards the impeller, is conveyed horizontally within the impeller housing, and is directed downward from the impeller housing as indicated by the arrow indicated by "E". According to the present invention, the impeller casing 2 is arranged between the top plate 3 and the bottom plate 4, which includes at least two inlets 11 on the top plate for introducing the material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com