Material mixer

A material mixer, main motor technology, applied in mixers, mixers with rotating containers, chemical/physical processes, etc., can solve the problems of uniform mixing of materials, hot melting of materials, easy to eat materials, etc., and achieve a simple and compact structure. , The effect of mixing evenly and fully, and the cylinder rotating speed is slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

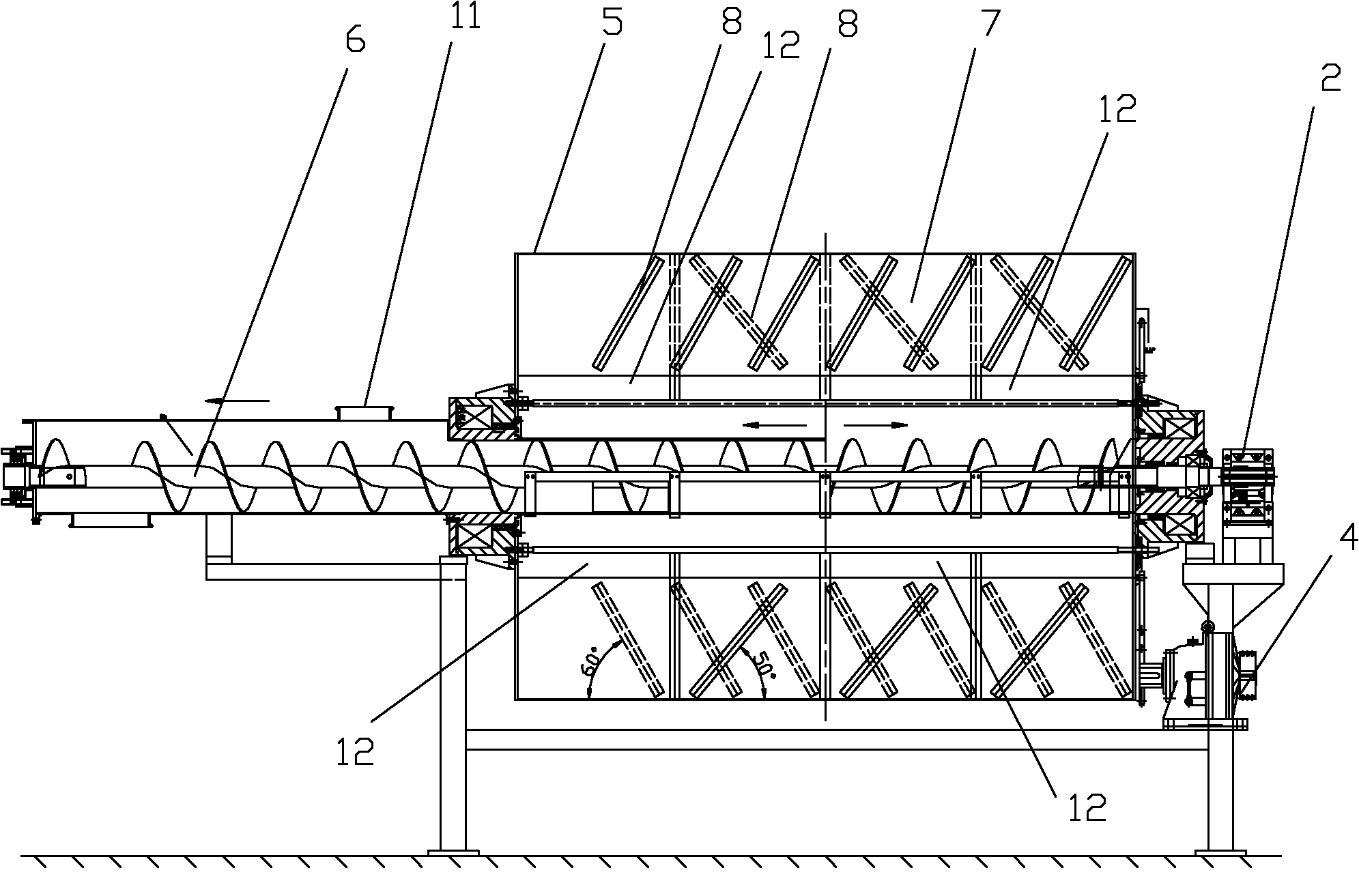

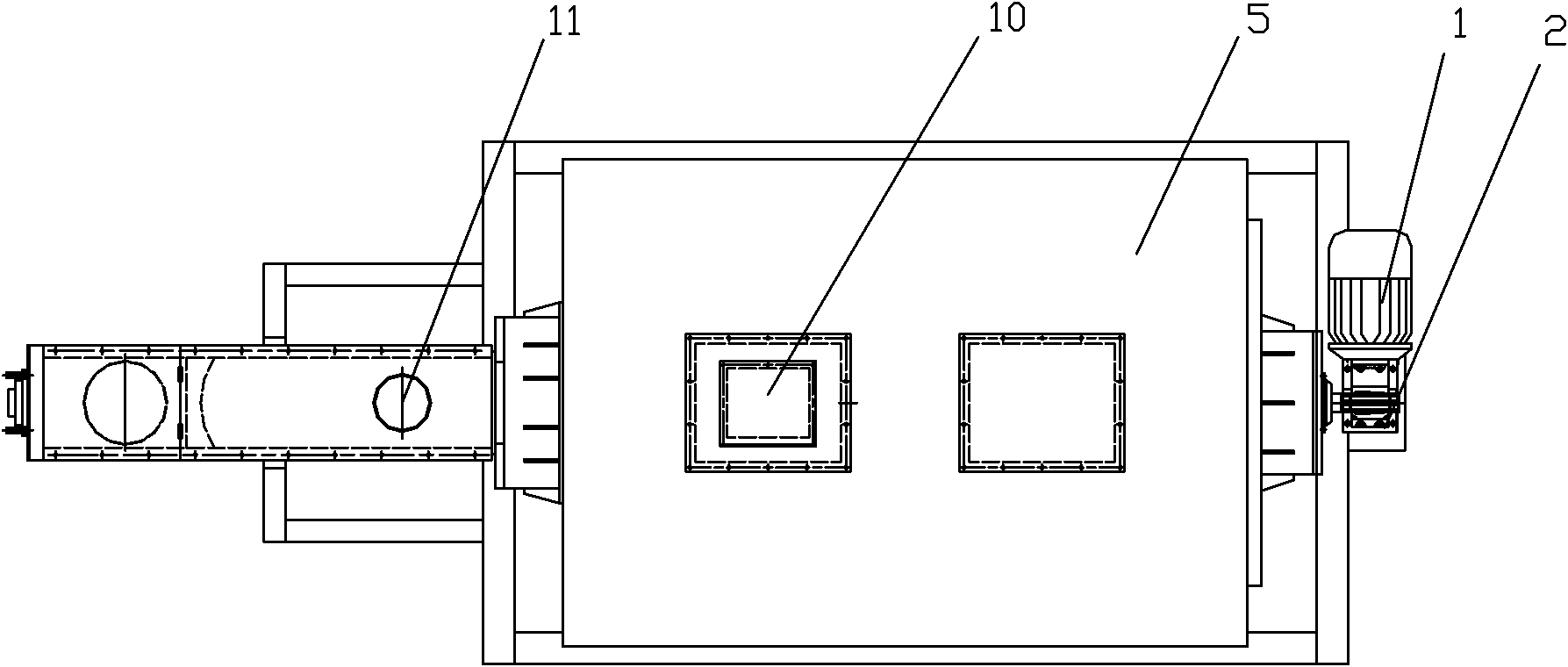

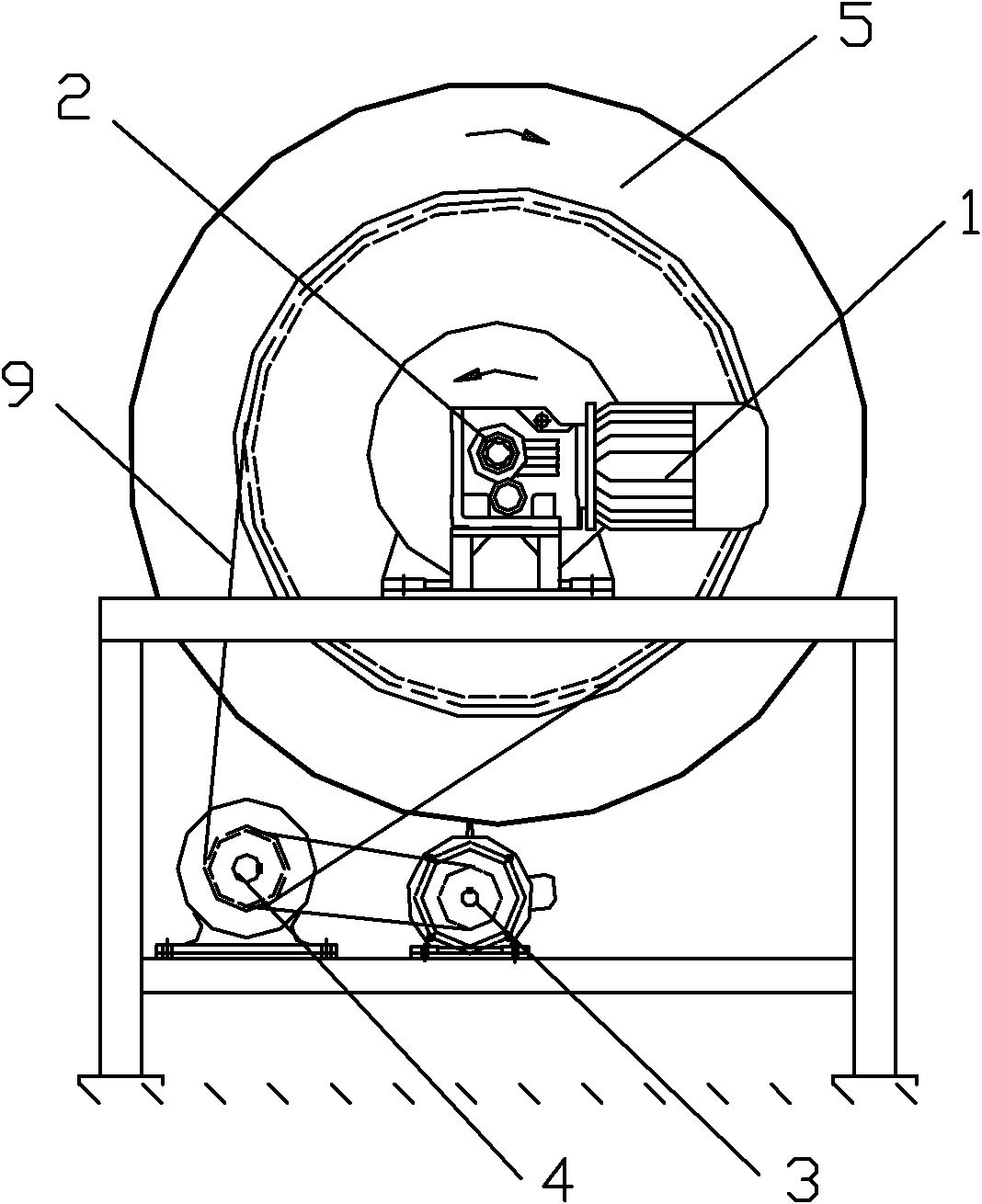

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the material mixer includes a main motor 3, an auxiliary motor 1, a main reducer 4, an auxiliary reducer 2 and a cylindrical cylinder 5, the cylinder 5 is equipped with a rotating shaft 6, and the rotating shaft 6 is provided with a spiral The screw shaft of the blade, the rotating shaft 6 is divided into two parts, the left and the right, and the helical direction of the spiral blade in the left and right parts of the rotating shaft 6 is opposite. The opposite end of 7 points to the orientation of the rotating shaft 6 and deviates a certain distance from the center of the rotating shaft 6 , and the bearing plate 7 is also provided with a guiding scraper 8 .

[0026] Specifically, a blanking groove 12 is formed at one end of the bearing plate 7 close to the rotating shaft 6 .

[0027] Specifically, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com