Electrically operated shaving appliance

A kind of equipment, electric technology, applied in the direction of metal processing, etc., can solve the problem of high manufacturing cost of shaving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

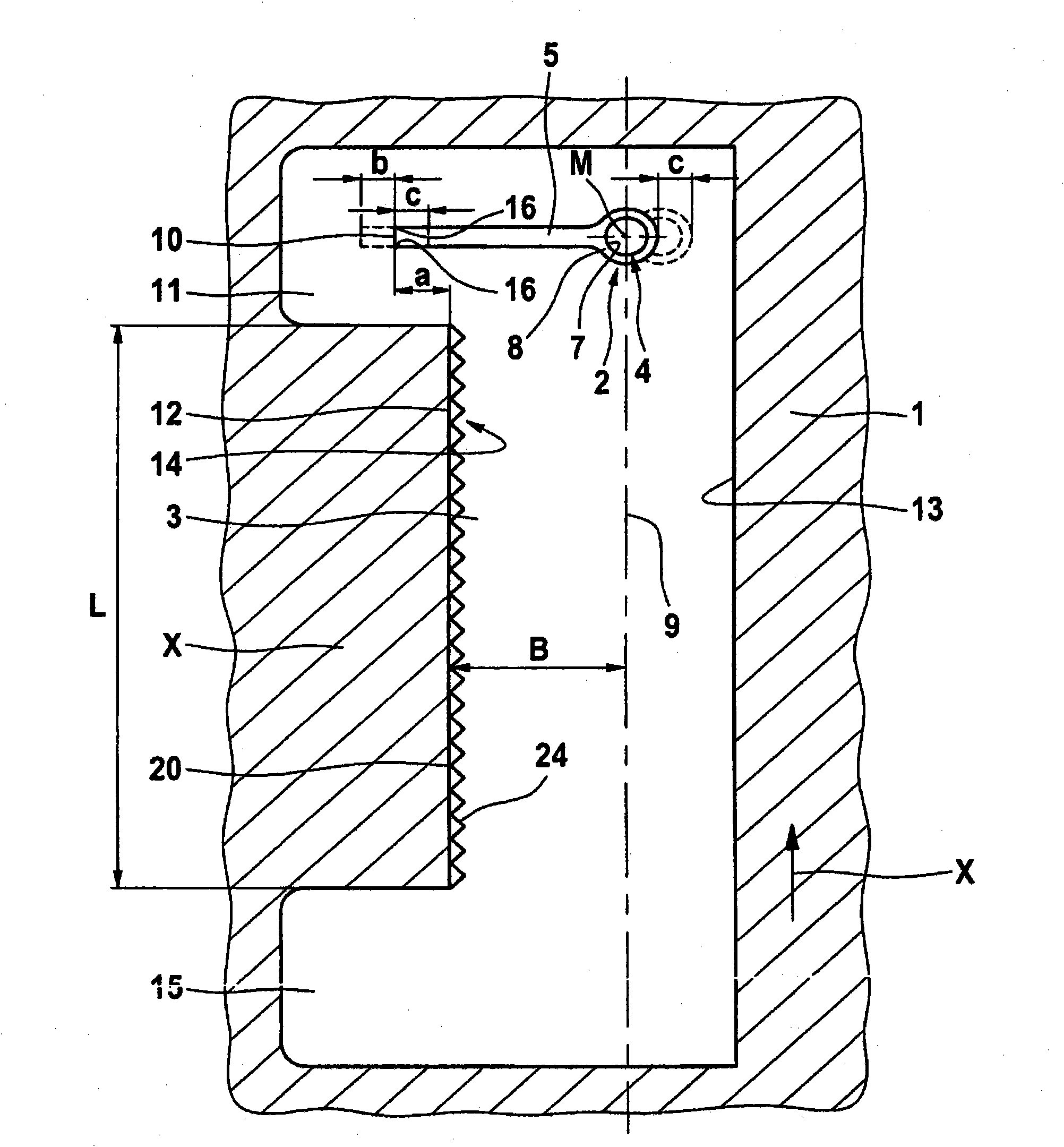

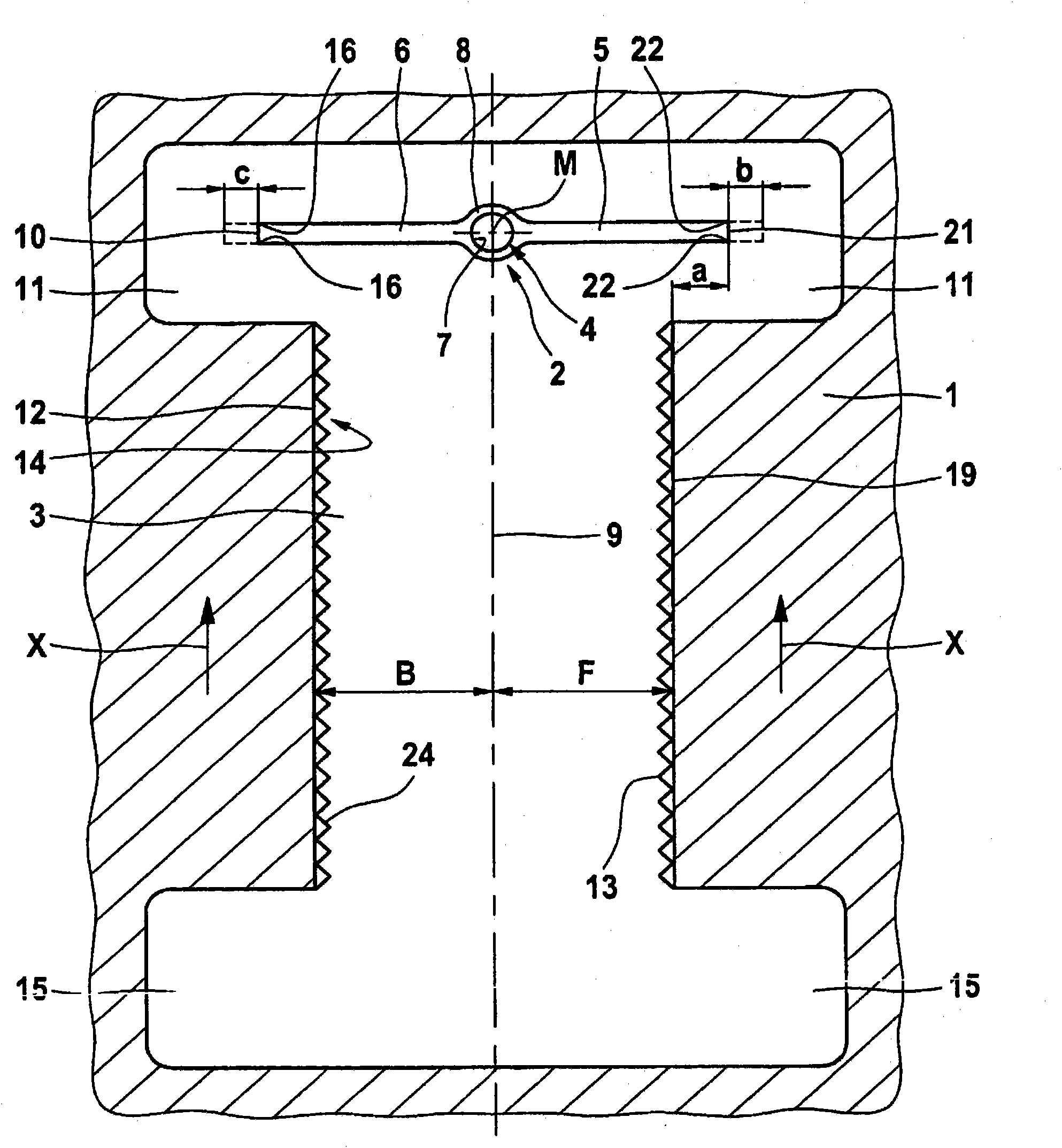

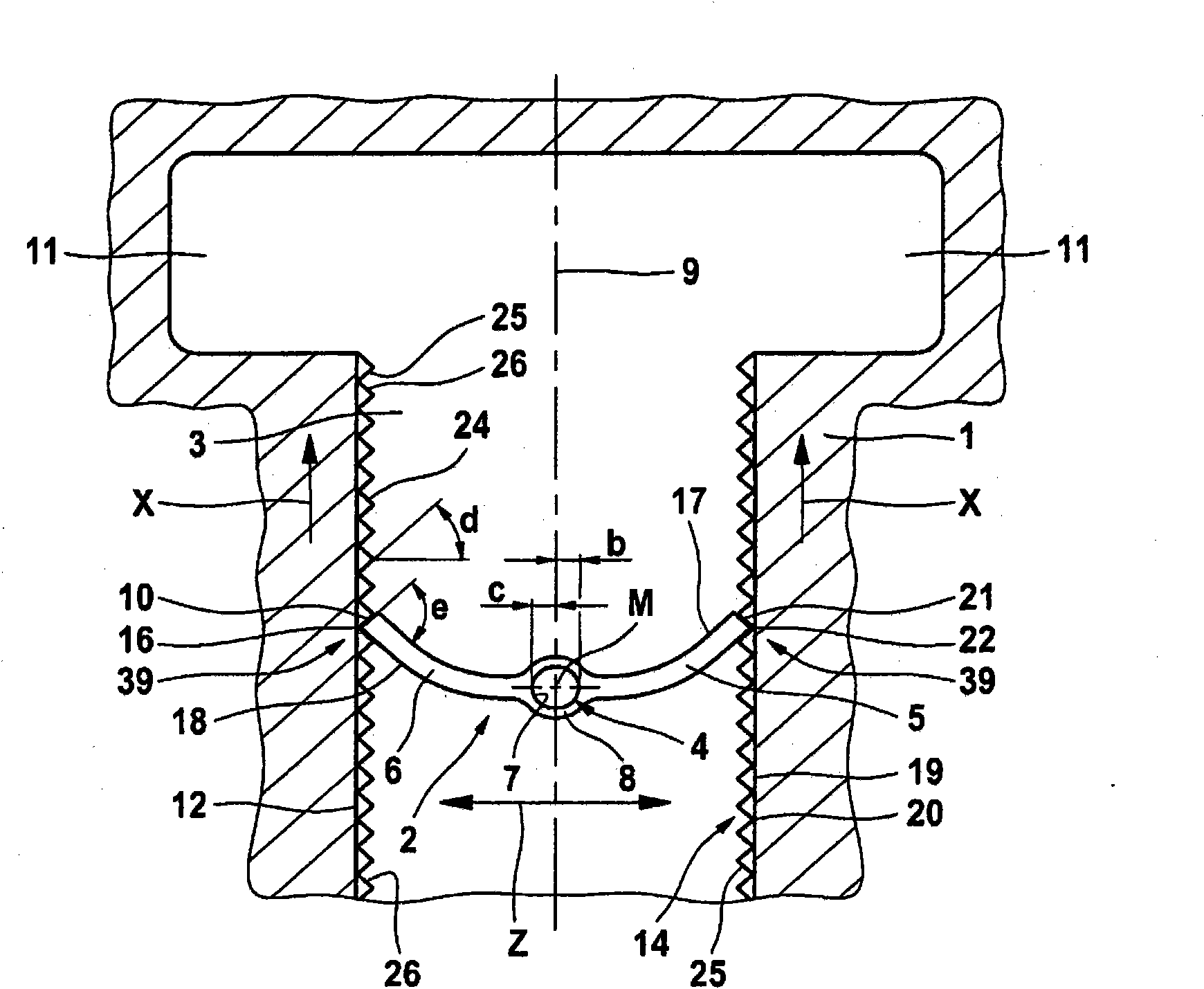

[0025] First, it should be mentioned that, Figure 1 to Figure 4 Only one section of the razor housing 1 is shown, on which the deflection device 2 can act. The illustrations are sufficient to clearly illustrate the invention. However, in order to better understand the connection between the present invention and the razor housing of the shaving apparatus, Figure 5A shaving device 25 is shown having a first cutting system 28 on the front face 26 of the shaving device 1 which can be brought into an extended or retracted position. The cutting system 28 consists of a long hair cutter having comb-shaped upper and lower blades 30, 31 which slide along each other and extend transversely to the razor housing 1 and protrude forward from said housing so as to way to better reach the user's skin surface. On the front side, a second cutting system 32 is arranged with two razor foils 33 , 34 next to each other and corresponding thereto two lower blades (not shown) swinging back and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com