Device and method for detecting mounting angle of Heidenhain length gauge

A technology of installation angle and detection device, which is applied in the non-contact measuring device and HEIDENHAIN field of horizontal installation, can solve the problems that it is difficult to apply to the measurement of large-diameter optical components, increase the risk of primary mirror detection and handling, and limit the measurement accuracy. Achieve the effect of simple structure, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

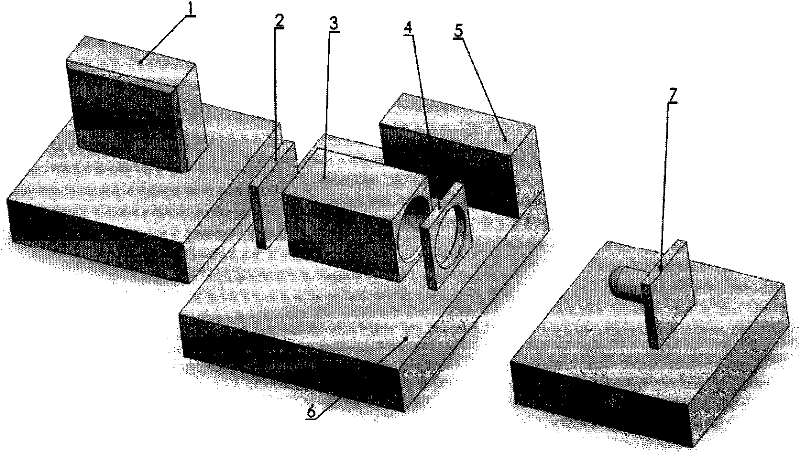

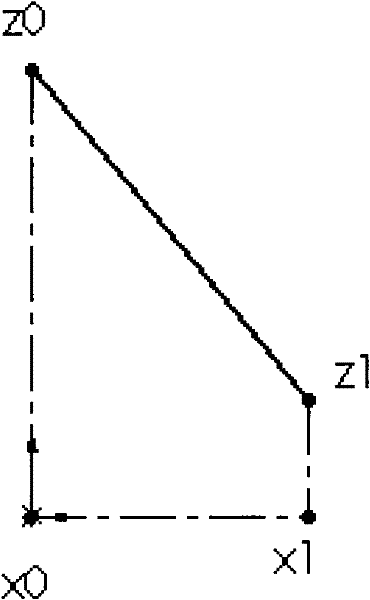

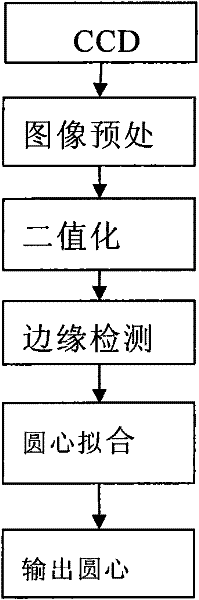

[0029] Such as figure 1 As shown, figure 1 The HEIDENHAIN Length Gauge 7 is installed horizontally. The detection device of the present invention is composed of a computer system 1, a CCD2, an imaging lens and its holder 3, an aperture 4, a level 5 and an adjustable base 6. The level 5 is located on the adjustable base 6, and used in conjunction with the adjustable base 6, so that the upper surface of the adjustable base 6 is in a horizontal position, thereby ensuring that the plane of the CCD2 is perpendicular to the ideal installation position of HEIDENHAIN; the imaging lens and its bracket make The spherical head of the measuring rod of the HEIDENHAIN length gauge 7 is imaged on the CCD plane; the diaphragm 4 is used to limit the imaging range; the computer system 1 is connected with the high-precision CCD2 to collect and process images. One measurement needs to collect two images. Heidenhain Length Gauge 7 collects one picture when the ball head of the measuring rod is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com