Integrated vertical garbage compressor

A garbage compressor and garbage compression technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of inability to receive and store garbage, affect production efficiency, and consume energy for sewage discharge, so as to improve the efficiency of garbage transfer , Improve the production environment and reduce the effect of operating failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

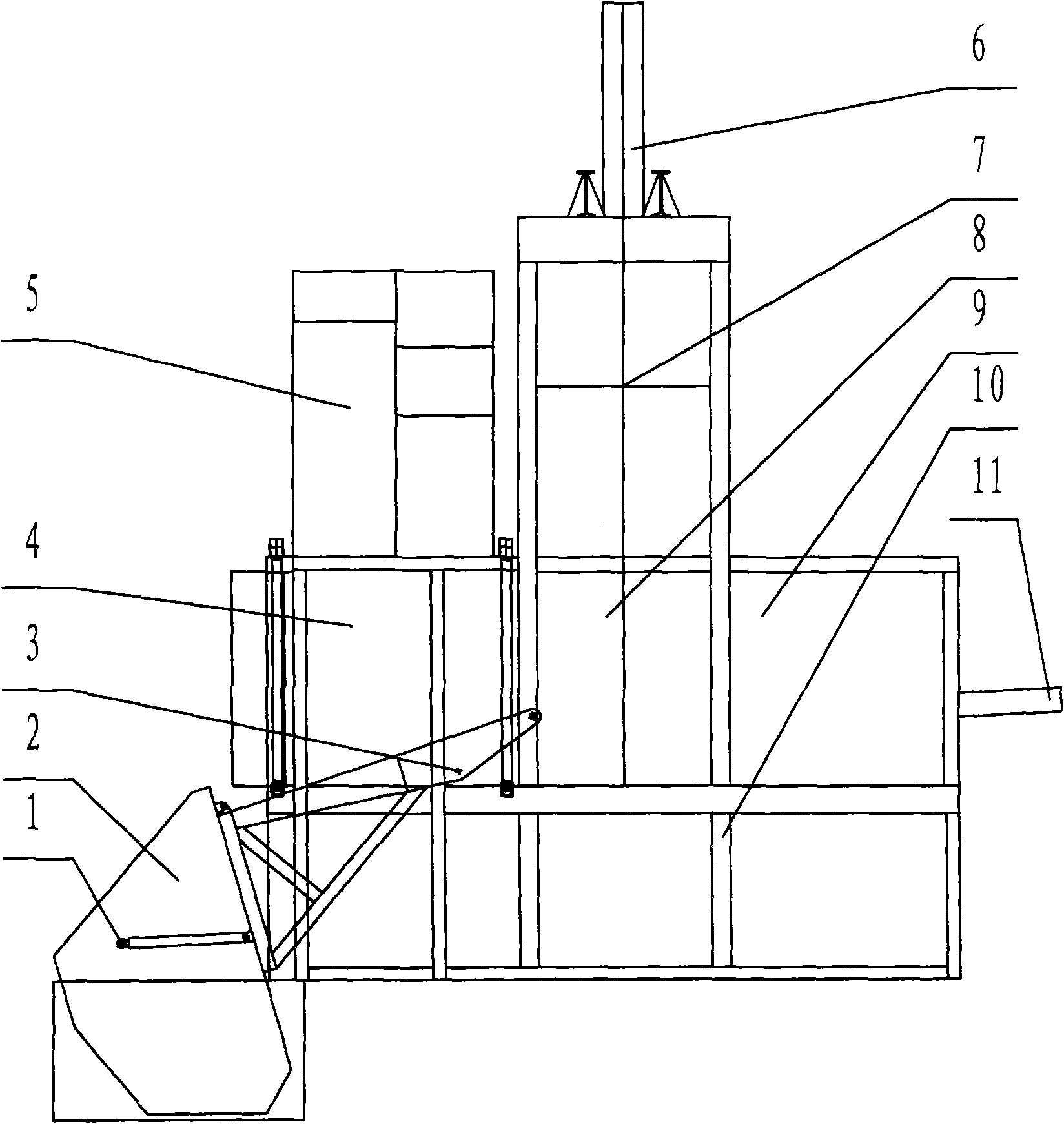

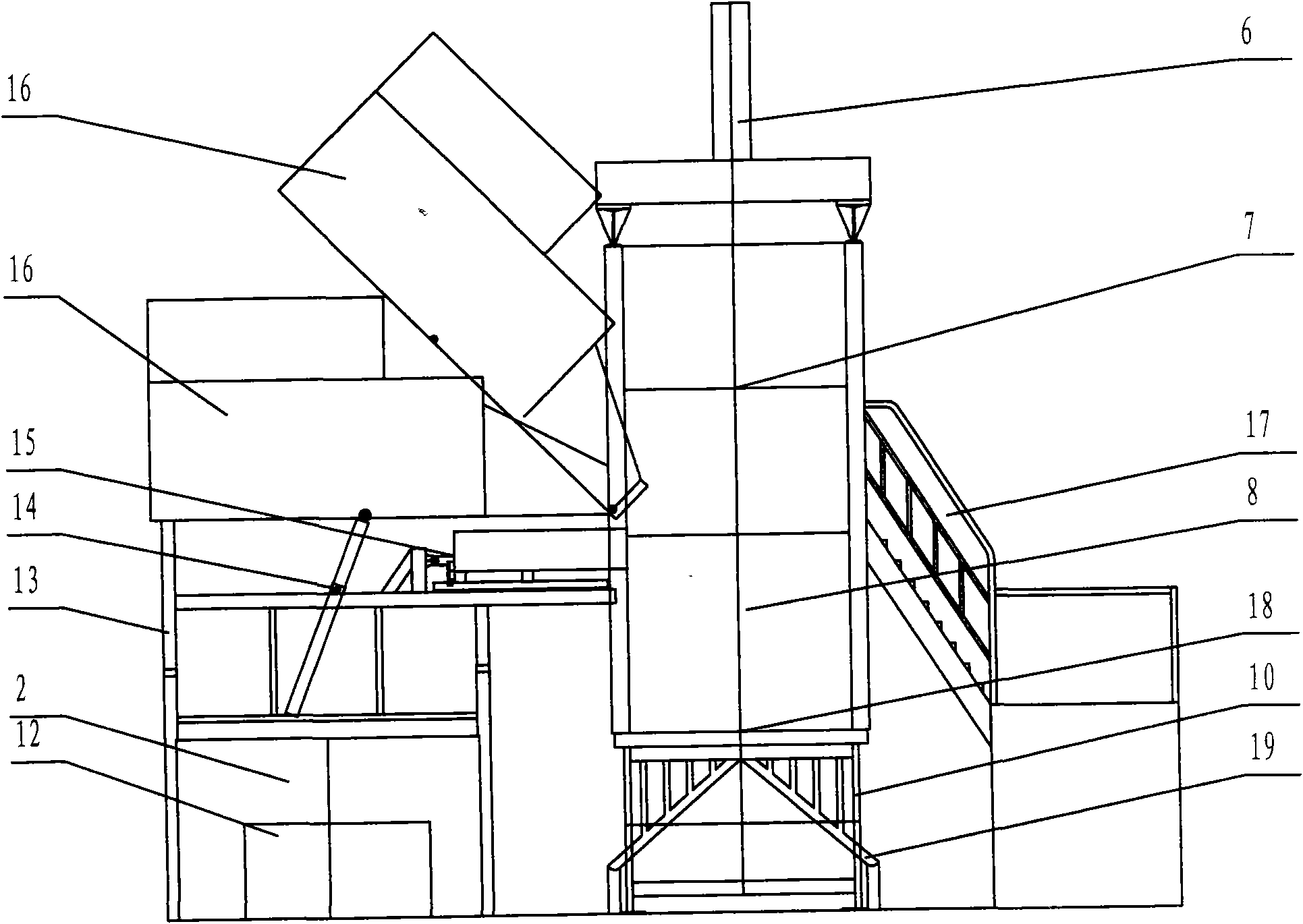

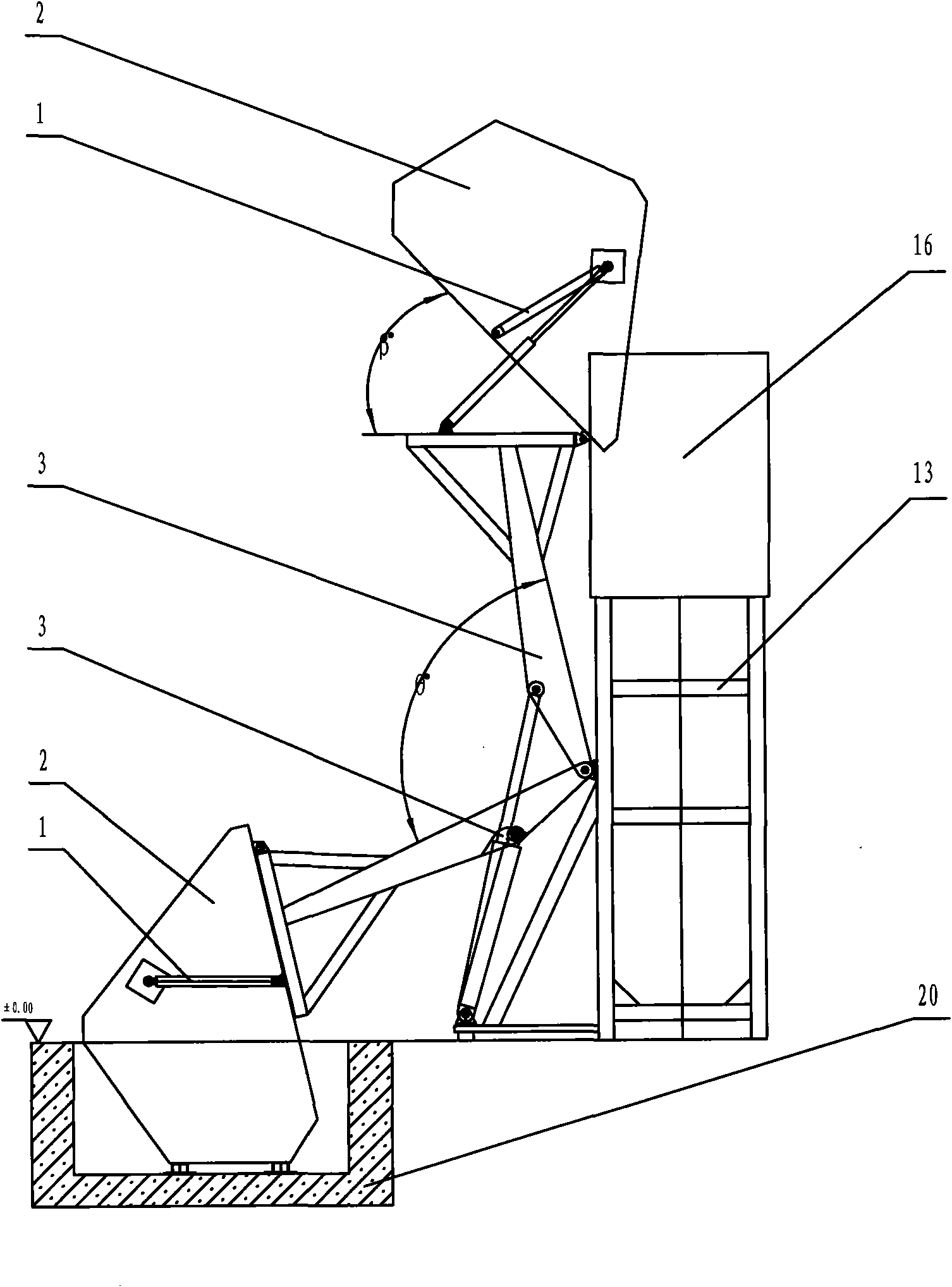

[0013] Such as Figure 1 ~ Figure 3 As shown, the integrated vertical garbage compressor of the present invention includes a garbage receiving mechanism, a garbage storage mechanism, a garbage pile shape processing mechanism 15, a garbage collection compression bin 8, a dense garbage block storage bin 4 and a dense garbage block transfer mechanism installation bin 9. An integrated box body, a compact garbage block transfer mechanism 11, a garbage compression mechanism 7, and a compression bin sewage potential energy discharge mechanism 19 placed below the compression box; the garbage receiving mechanism includes a garbage receiving hopper 2 and a hopper placed in the pit 20 The primary turning mechanism 3 and the secondary turning mechanism 1 of the hopper; the garbage storage mechanism includes a high storage trough 16, a high storage trough turning mechanism 14 and a high storage trough support 13; the garbage pile shape processing mechanism 15 includes actions Mechanism and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com