Millesimal fine adjustment tool rest

A thousand-point fine-tuning, tool holder technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of adjustment, unrealistic tool setting, unintuitive, time-consuming, etc., to reduce process costs and save adjustment. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

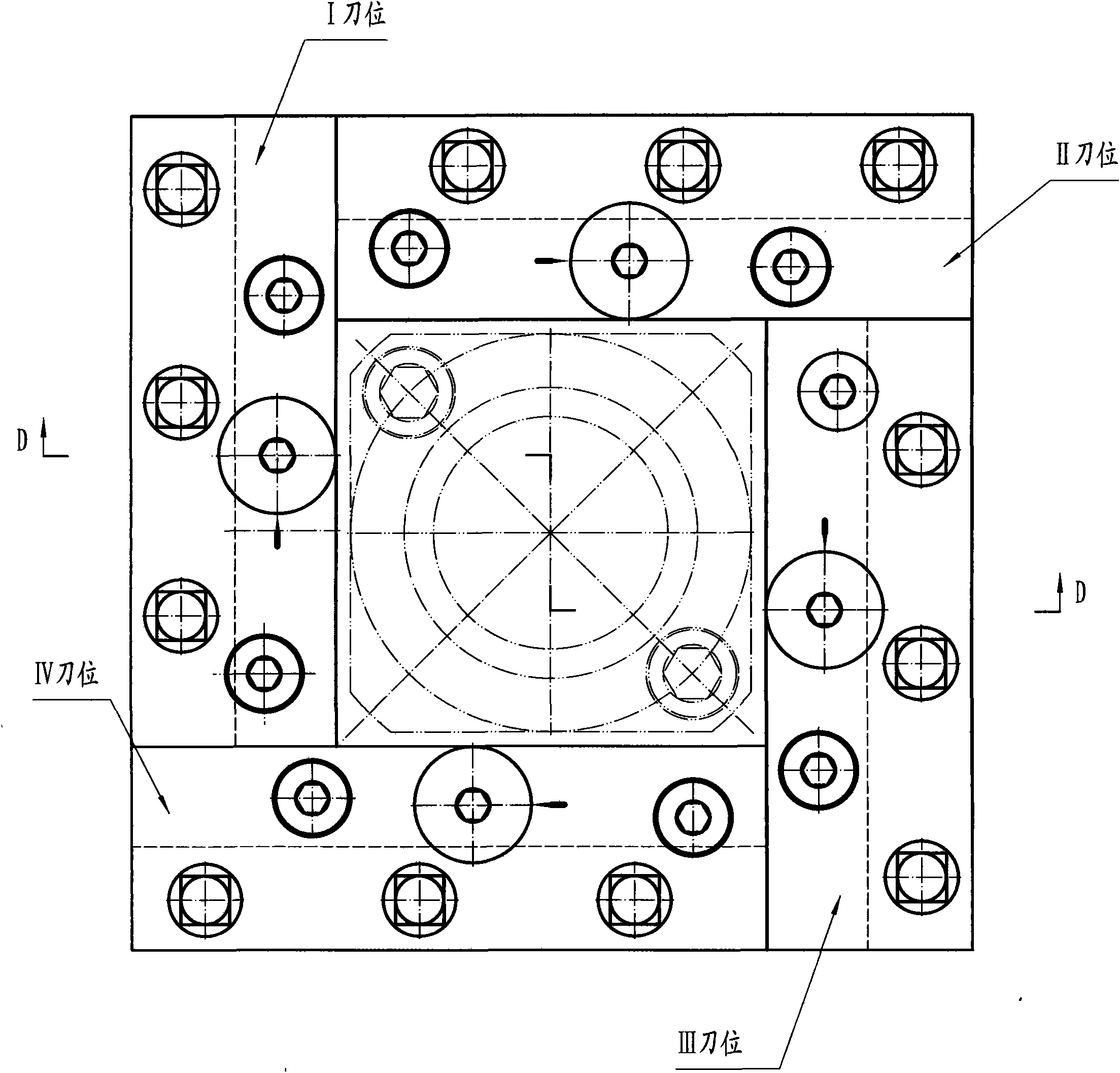

[0027] figure 1 Among them, the four tool positions are distributed on the four sides of the tool holder body.

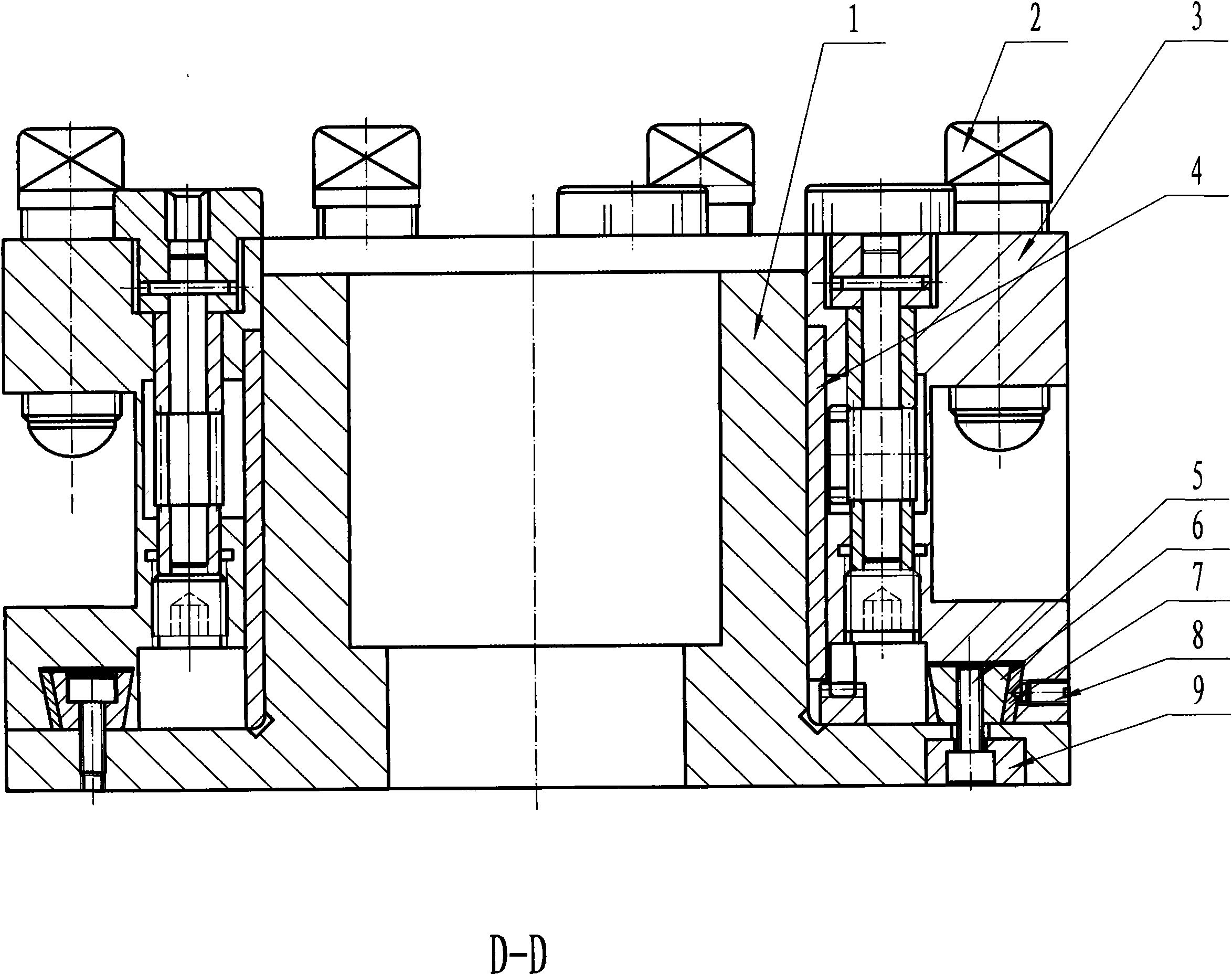

[0028] figure 2 Among them, each tool position body (3) is contained in the structure mode on the tool rest body (1). The special screw (5) fixes the guide rail (6) on the tool holder body (1), the sliding gap between the guide rail (6) and the inner surface of the tool position body (3) is adjusted by the relative rotation angle of the eccentric sleeve (9), and the outer surface The sliding gap is adjusted by the insert (7). After the adjustment is appropriate, the guide rail (6) is fixed vertically and laterally by the special screw (5) and the adjustment screw (8), so that the knife position body (3) can move in a straight line. play a guiding role. The hollow part of the tool holder body (1) is the interface between the tool holder indexing mechanism and the electric tool holder indexing mechanism of a general-purpose lathe. An ordinary general-purpose lath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com