Dustproof case

A case, dust-proof technology, applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of reducing the overall strength of the case, large electromagnetic radiation of the case, and reducing the air passing rate, etc., to achieve low noise, electromagnetic Low radiation, the effect of promoting air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

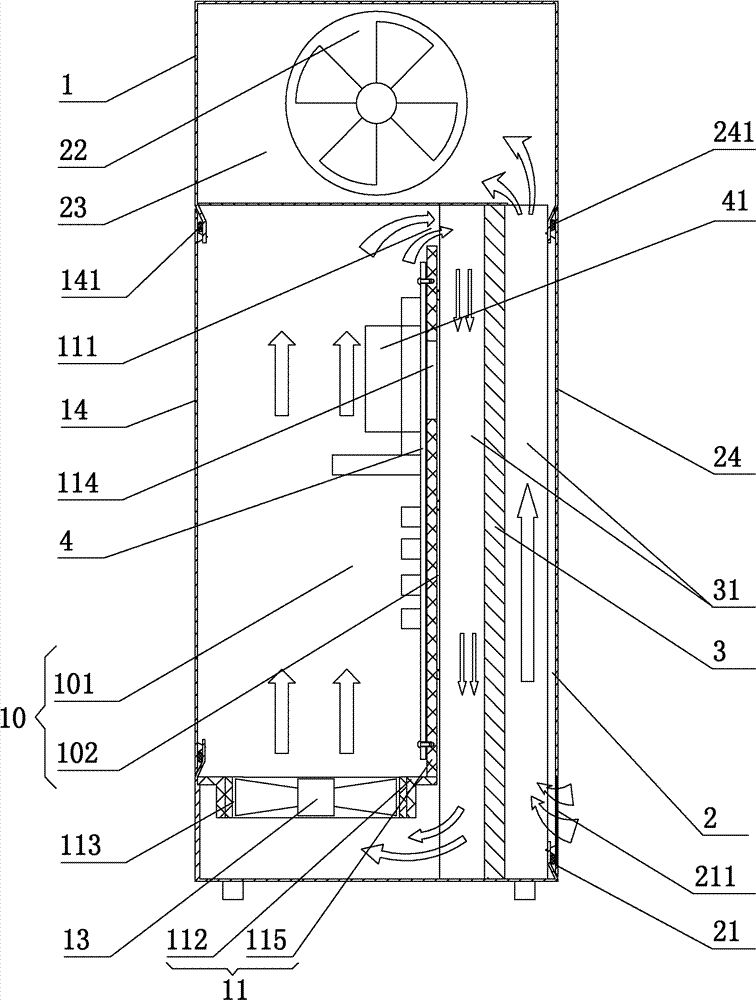

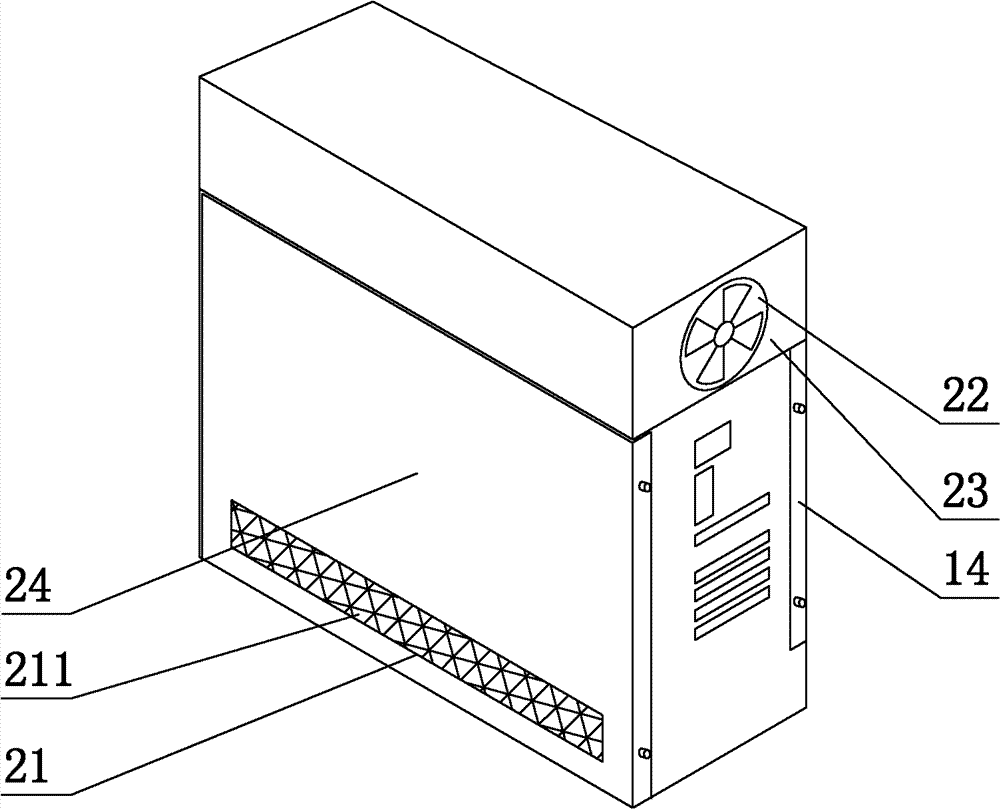

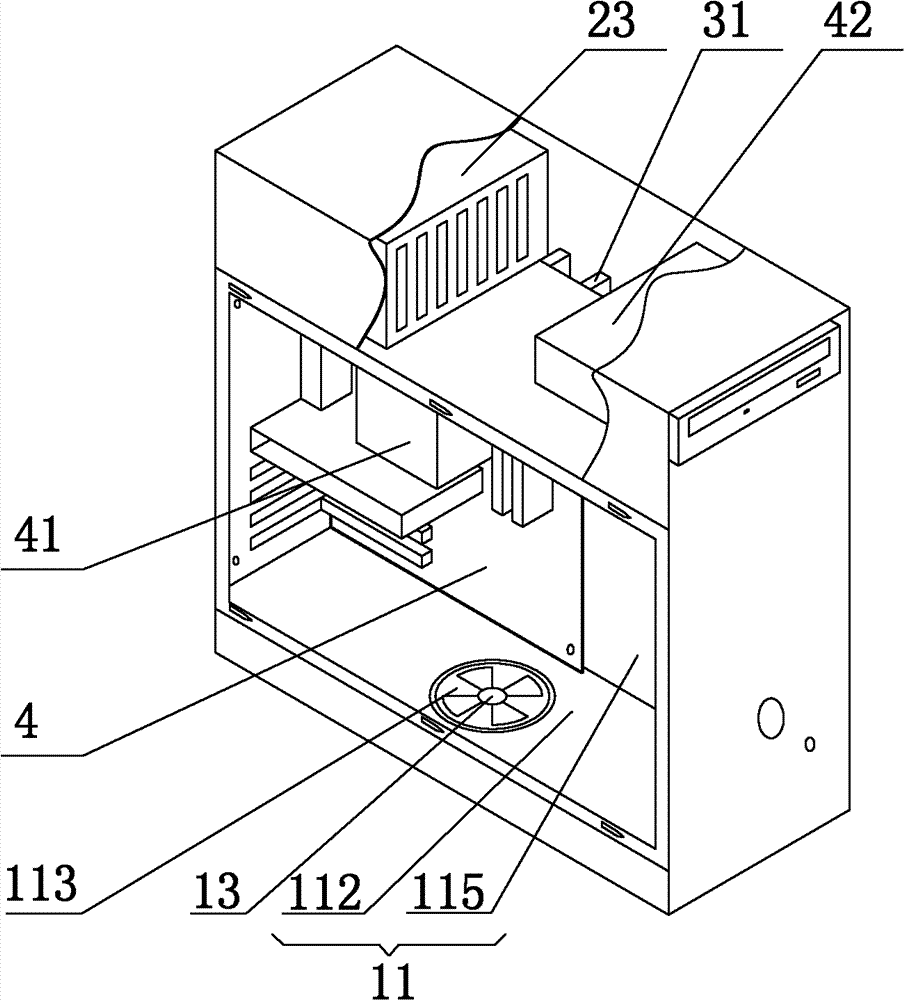

[0022] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the dustproof cabinet of the first embodiment of the present invention includes a cabinet 1 and a cabinet inner chamber 10 located inside the cabinet 1. The cabinet inner chamber 10 is a closed cavity, and one side of the cabinet inner chamber 10 is provided with a Heat exchange heat sink 3.

[0023] In this embodiment, the cooling plate 3 is arranged on the right side of the front view of the chassis cavity 10, and the chassis cavity 10 is provided with a partition assembly 11, and the partition assembly 11 divides the chassis cavity 10 into a main board accommodating cavity 101 and a The diversion cavity 102 is arranged between the partition plate assembly 11 and the heat sink 3 , the main board accommodating cavity 101 communicates with both ends of the diversion cavity 102 , and an internal circulation fan 13 is provided in the inner cavity 10 of the chassis. The partition plate assembly 11 is only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com