Bending resistance test device for valve

A strength test and anti-bending technology, applied in the mechanical field, can solve the problems of high cost, hidden safety hazards, difficult operation, etc., and achieve the effects of convenient operation, simple structure and accurate measurement values.

Inactive Publication Date: 2010-08-25

ZHEJIANG WORLD BRASS

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the actual inspection process, first of all, a pipe fitting is generally tightened at both ends of the valve and supported at a suitable position; then an object of appropriate weight is used to act on the valve body. This traditional method is not only difficult to operate, but also costly. High, there are potential safety hazards at work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

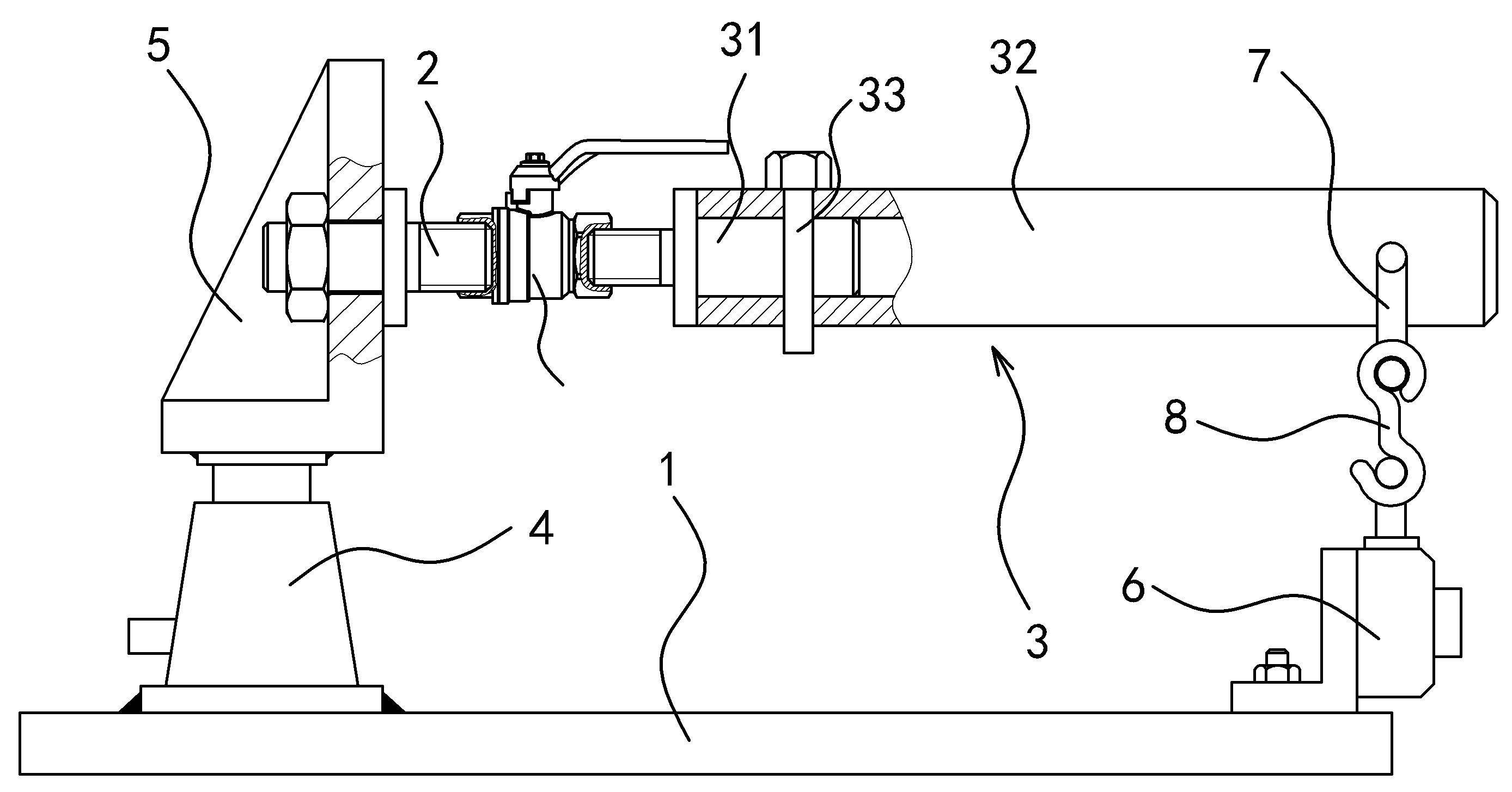

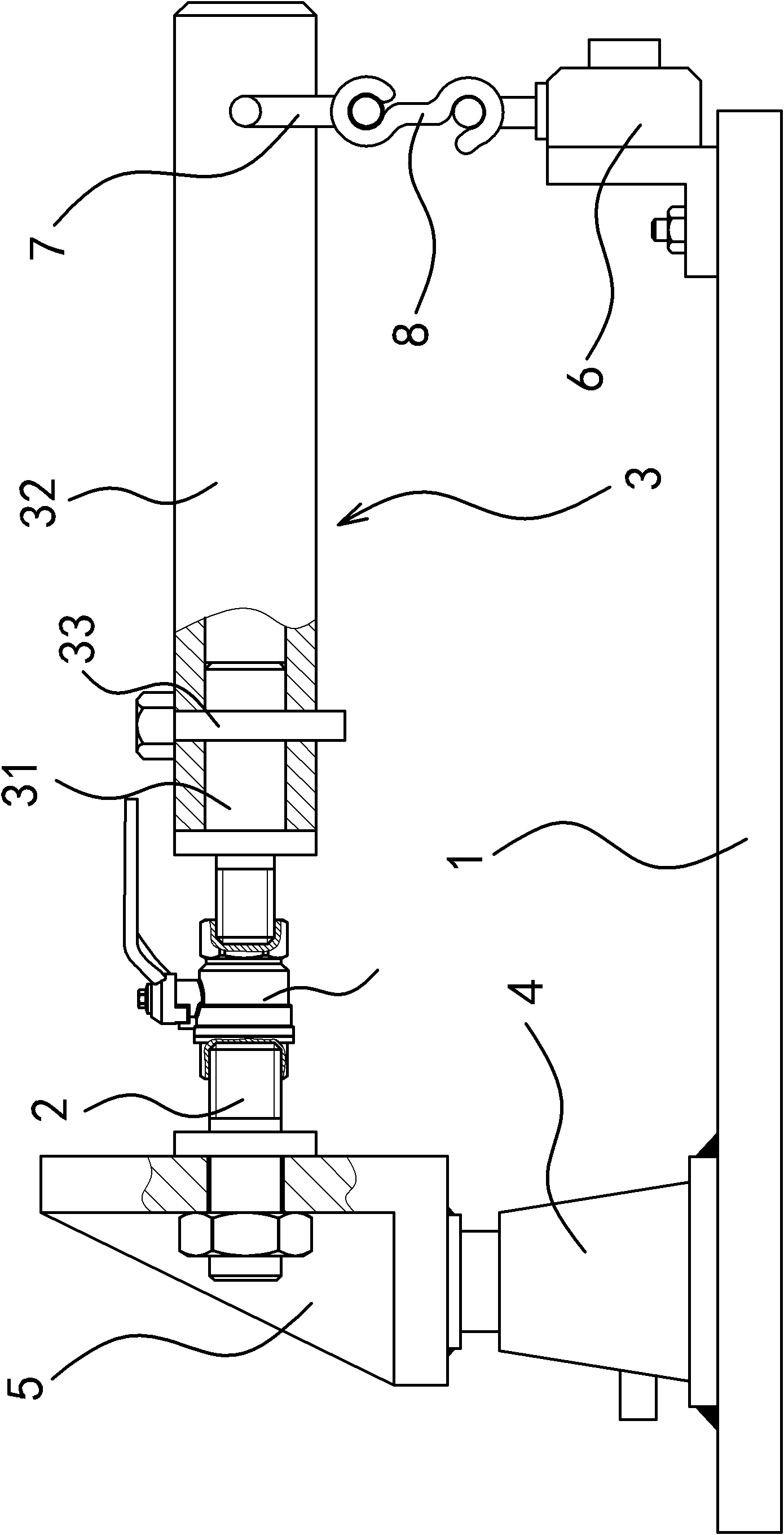

The invention provides a bending resistance test device for a valve, belonging to the technical field of machinery and solving the problems of difficult operation of the bending resistance of the traditional valve, high cost and potential safety hazard existing in operation. The bending resistance test device for the valve comprises a base, a connecting rod 1 and a connecting rod 2, wherein a force applying mechanism is fixed on the base, one end of the connecting rod 1 can be connected with one end of the valve and the other end can be fixedly connected with the force applying mechanism, the force applying mechanism can ensure the connecting rod 1 to bear a radial action force when the force applying mechanism is operated; and one end of the connecting rod 2 can be connected with the other end of the valve, and a force measurer capable of measuring a radial force-loading value of the connecting rod 2 is arranged between the other end of the connecting rod 2 and the base. The bending resistance test device for the valve has the advantages of simple structure, small occupation space, convenient operation and accurate measurement values.

Description

Valve bending strength test device technical field The invention belongs to the technical field of machinery, and relates to a test device, in particular to a valve bending resistance test device. Background technique Valves are one of the commonly used engineering components in people's life and production. With the development of society and the advancement of science and technology, products are not only updated and upgraded, but also product quality testing has been widely valued. The country has promulgated relevant testing specifications for the testing standards of valves. For the bending resistance test of valves, GB / T8464-2008 has made a clear description, but the specific equipment used has not been explained in detail. In the actual inspection process, first of all, a pipe fitting is generally tightened at both ends of the valve and supported at a suitable position; then an object of appropriate weight is used to act on the valve body. This traditional method i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M19/00G01M99/00

Inventor 卓旦春

Owner ZHEJIANG WORLD BRASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com