Method and device for calibrating three-dimensional micro tactile sensor

A tactile sensor and sensor technology, applied in measuring devices, electrical devices, optical devices, etc., can solve the problems of low accuracy, single signal, limited weak signal acquisition ability, etc., and achieve linkage and high-precision calibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

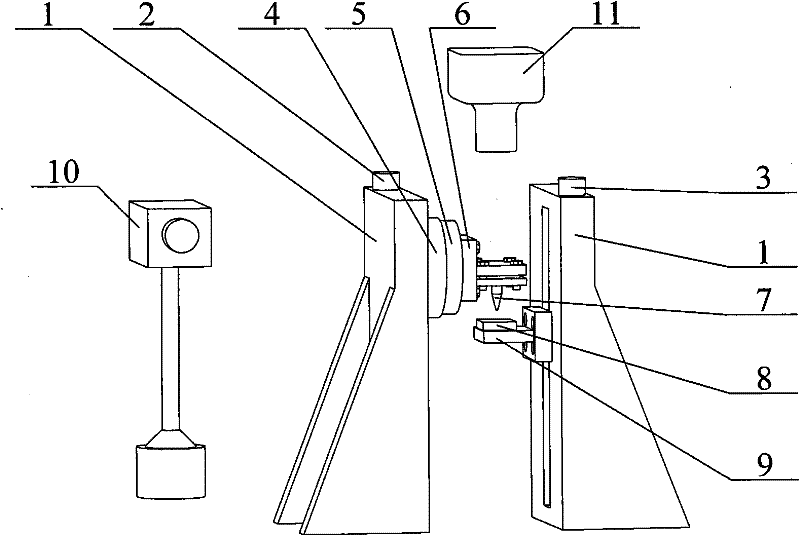

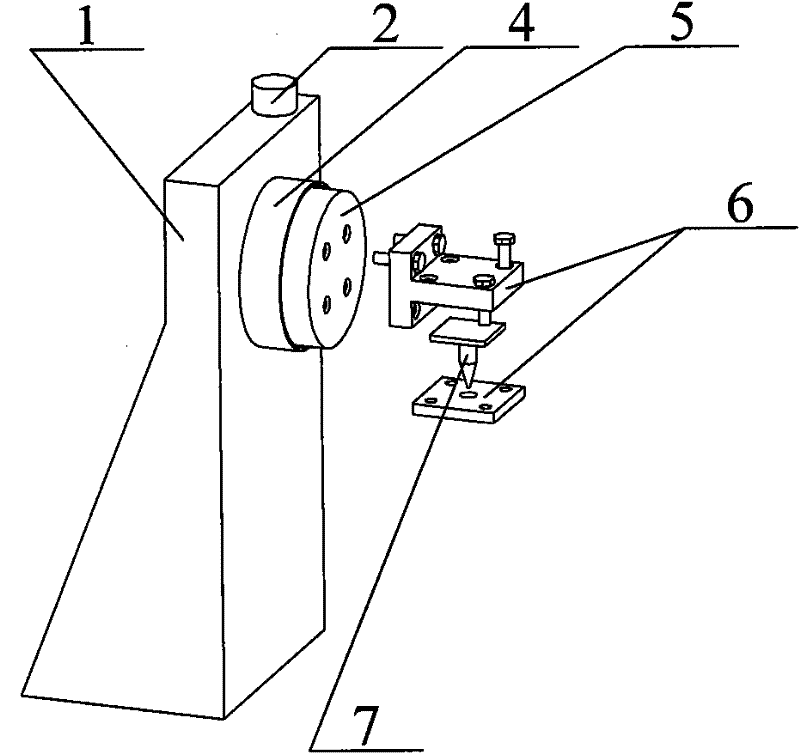

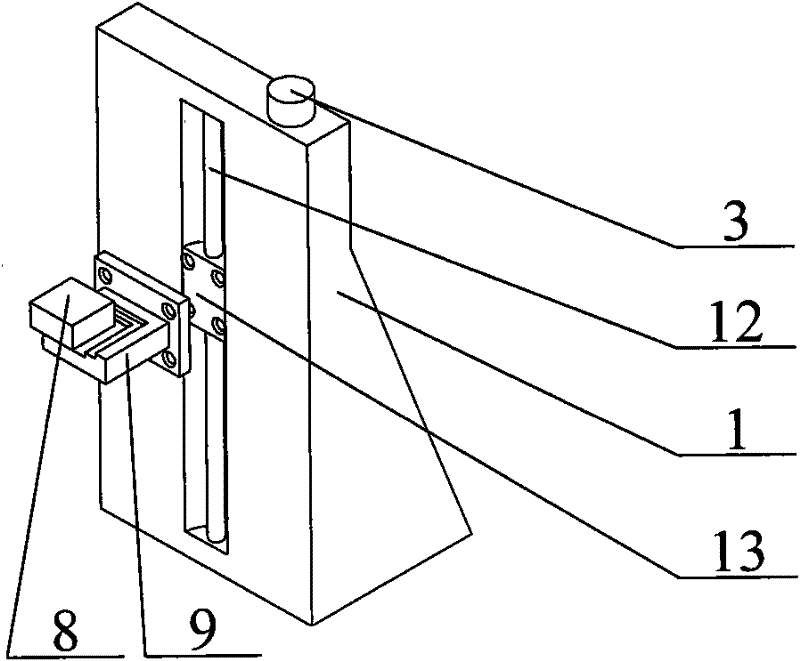

[0030] A calibration implementation method for a three-dimensional micro-tactile sensor. The three-dimensional micro-tactile sensor is fixed and positioned through a 1″ resolution rotating platform 5 and the clamping mechanism 6 of the three-dimensional micro-tactile sensor installed in different directions, and the piezoelectric ceramic 8 is fixed close to the Right below the three-dimensional micro-tactile sensor 7, and then realize the zero contact between the piezoelectric ceramic part and the three-dimensional micro-tactile sensor through manual / automatic control of the transmission mechanism. The entire measurement and calibration process passes through the CCD camera system 10 installed in the vibration isolation cavity, and the CCD The monitor monitors in real time, so as to clearly identify the degree of contact between the three-dimensional micro-tactile sensor components and the piezoelectric ceramics. After the three-dimensional micro-tactile sensor has zero contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com