Flow control valve

A flow control valve and fluid technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of low efficiency, complex structure, high cost, and achieve the effect of low noise and no magnetic field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

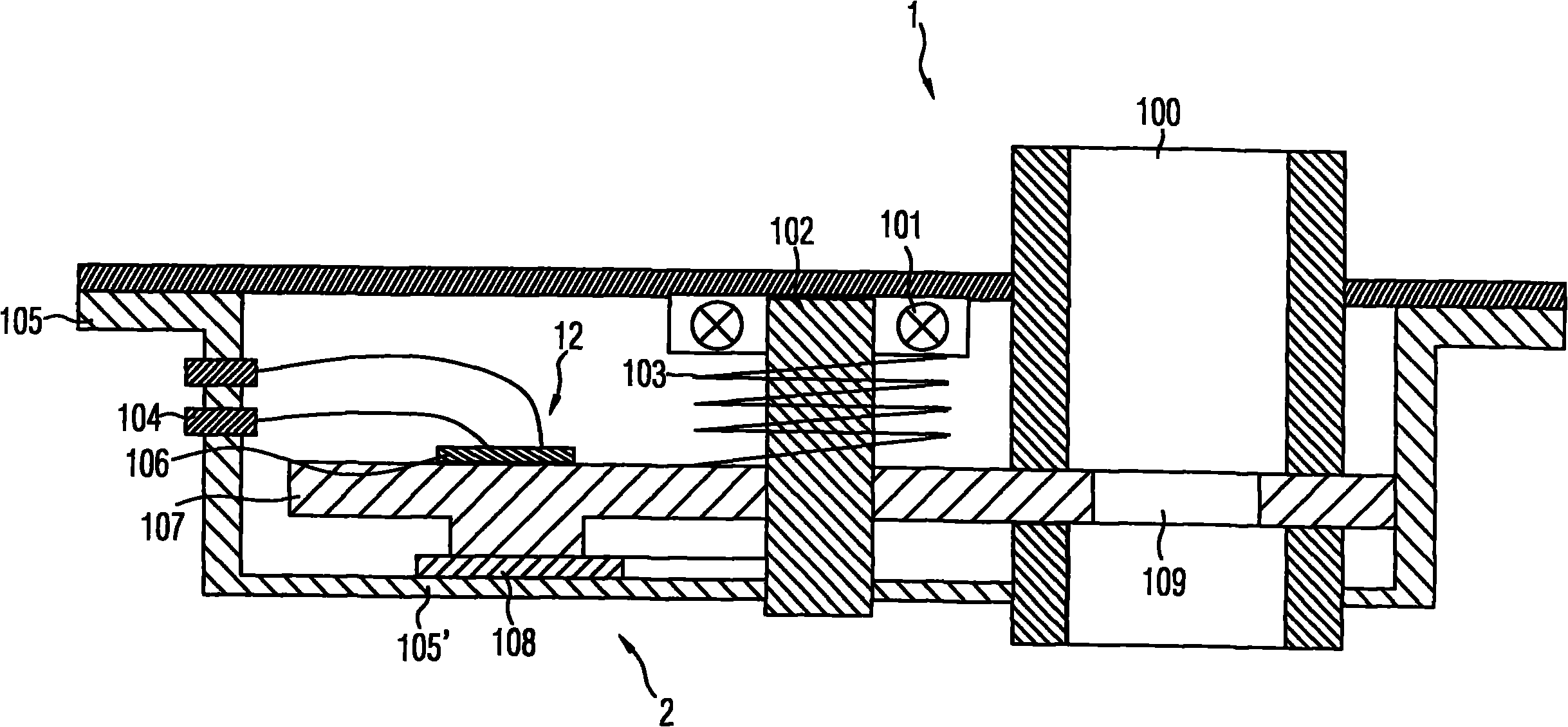

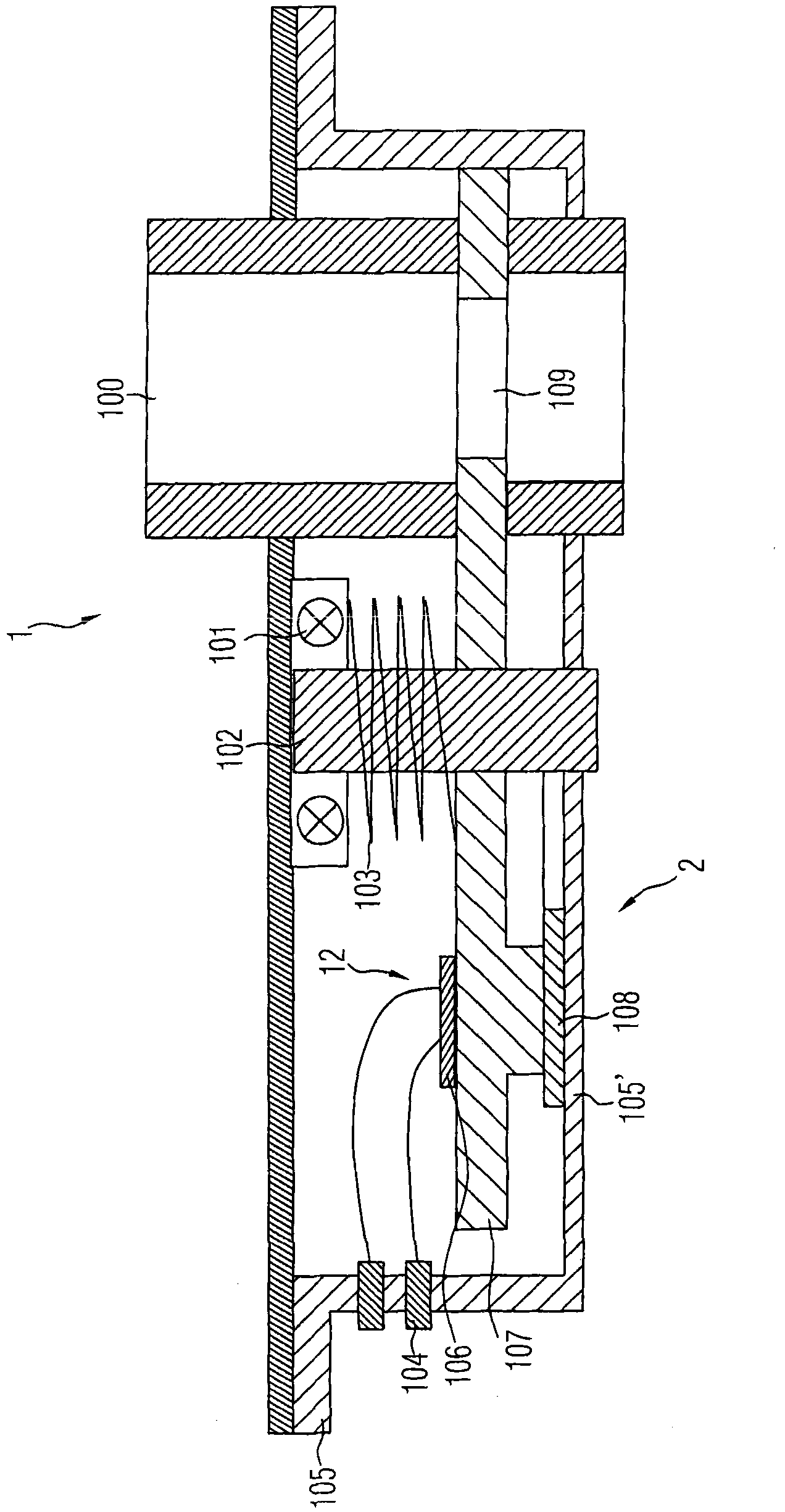

[0041] Fig. 1 is a schematic cross-sectional view of a flow control valve according to a specific embodiment of the present invention. As shown in the figure, the flow control valve 1 of this embodiment has a pipeline 100 for fluid to pass through, and a rotating piece 107 for cutting off the pipeline 100 is arranged along the vertical direction of the pipeline 100. The pipe 100 overlaps the opening 109 , wherein the diameter of the opening 109 is not larger than the outer diameter of the pipe 100 .

[0042]It can be seen from the figure that the pipeline 100 is actually composed of two parts separated by the rotating piece 107, and the rotating piece 107 is vertically i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com