Drilling platform pipe racking system and method

A drilling platform and drill pipe technology, which is applied to drill pipes, drilling equipment, drill pipes, etc., can solve the problems of low work efficiency of the drilling platform pipe arrangement system, save space, improve production efficiency, and simplify equipment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

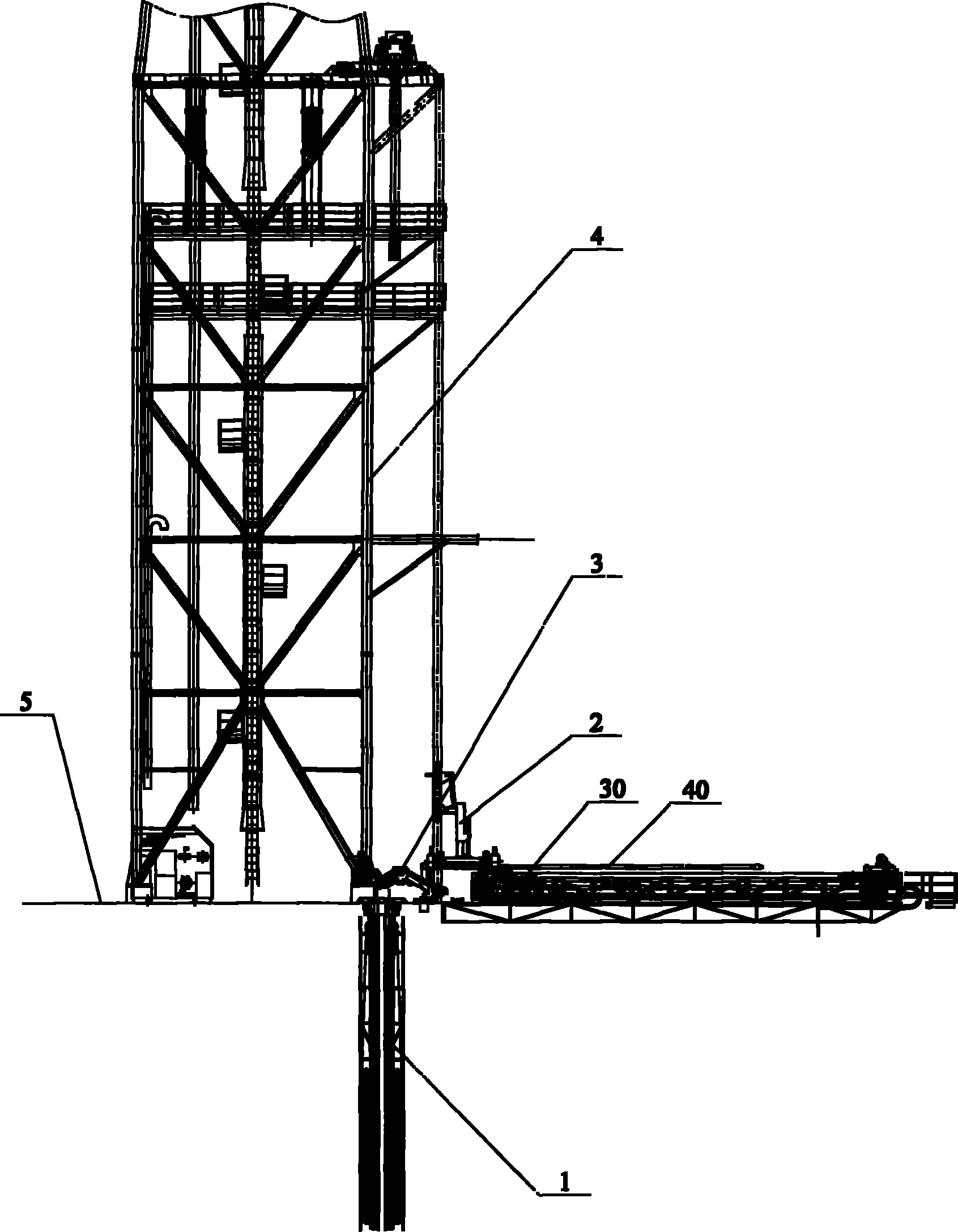

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] As shown in Fig. 1, the present invention comprises multi-station rat hole 1, derrick 4, pipe gripping manipulator 2 and iron driller 3, and described multi-station rat hole 1 is fixed below drilling platform 5, and provides at least two Drill pipe insertion station; the derrick 4 is fixed on the drilling platform 5; the pipe grabbing manipulator 2 is fixed on the derrick 4, and is used to pick up the drill pipe 40 conveyed by the catwalk machine 30 and put it into the mouse hole body and from Drill pipes are raised from the mouse hole body; the iron driller 3 is arranged on the drilling platform and is used for docking two drill pipes.

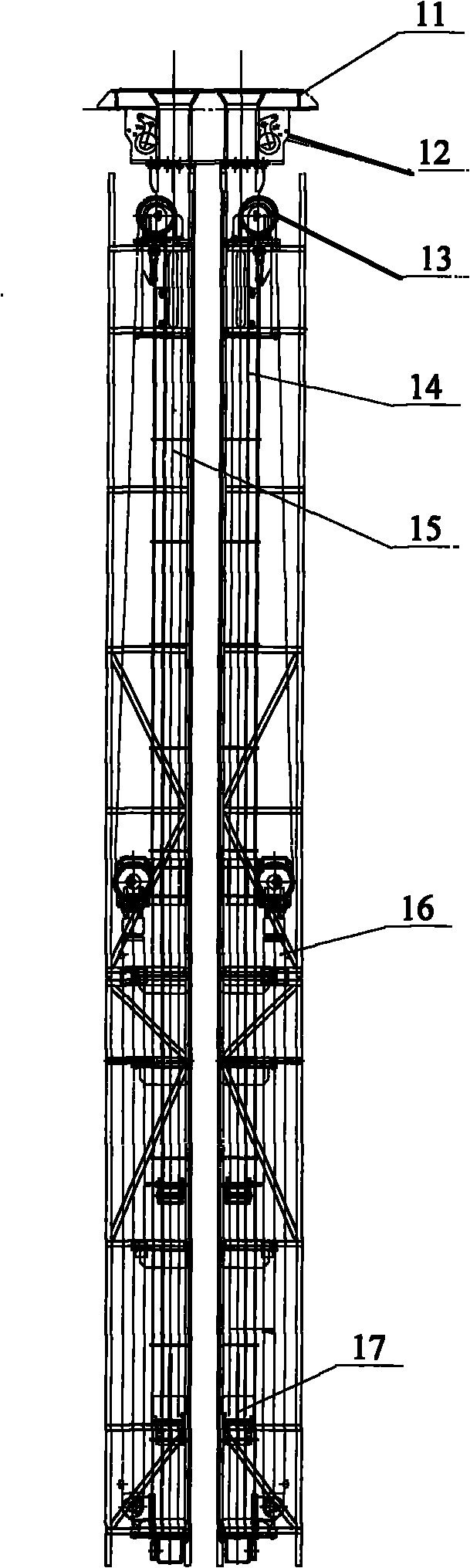

[0024] As shown in Figure 2, the multi-station rathole includes a top support frame 11, two rathole bodies 14, 15 and a drill pipe centering device 12, a lifting hydraulic pressure Cylinder 16, drill pipe buffer device 17 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com