A type zeolite and preparation method thereof

A zeolite and paper technology, applied in the field of A-type zeolite and its preparation, can solve the problems of high production cost of A-type zeolite, reduced zeolite performance stability, difficulty in controlling zeolite quality, etc., and achieves increased market competitiveness and fast crystallization speed. , the effect of significant economic benefits

Inactive Publication Date: 2010-08-25

杨辉

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a type A zeolite and its preparation method; to solve the problems of high production cost and complicated process steps of type A zeolite in the prior art, and mainly solve the problem of using rice husk ash, bagasse ash, diatomaceous earth, etc. When the combustion ash is used as raw material, the performance stability of the generated zeolite is reduced, and it is difficult to control the technical problem of the quality of the zeolite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2A

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

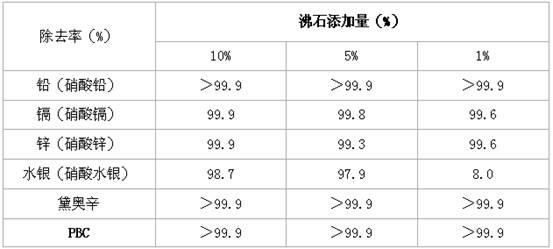

The invention provides an A type zeolite and a preparation method thereof. The invention solves the problems of high manufacture cost and complex process step of the A type zeolite in the prior art and the technical problems of reduced performance stability of the generated zeolite and difficult control of zeolite quality when the combustion ash, such as paddy husk ash, bagasse ash, diatomite, and the like are adopted as raw materials. The A type zeolite is prepared from burning ash, the main component of which is SiO2, as a raw material in an alkaline solution through hydrothermal reaction. The method comprises the following steps of: hydrothermally dissolving the burning ash in the alkaline solution; adding sodium metaaluminate for crystallization; washing in water, filtering and drying to obtain the A type zeolite. The method has shorter reaction time, high crystallizing speed, more favorable and stable performance of the generated A type zeolite and obvious economic benefit, obviously reduces the production cost, simplifies the preparation step, and improves the yield and the market competition of products.

Description

technical field The invention belongs to the technical field of A-type zeolite, and more specifically relates to an A-type zeolite and a preparation method thereof. Background technique Previously, zeolites were produced by various methods. Among them are production methods using industrial waste as raw materials. For example, using combustion ashes such as rice hull ash, bagasse ash, and diatomaceous earth as raw materials to produce zeolite, but due to the SiO in these combustion ash 2 with Al 2 o 3 The content ratio of zeolite is often uncertain and not a stable fixed value, so the performance stability of the generated zeolite is reduced, and it is difficult to control the quality of zeolite. Generally speaking, due to the SiO contained in these combustion ash 2 and Al 2 o 3 , if the hydrothermal reaction is carried out directly in the alkaline solution, when the initial reaction is carried out in the alkaline hot water, the two components are selectively dissolve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B39/14B09B3/00

Inventor 古川祖东

Owner 杨辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com