Novel V-B consistometer

A Weibo consistency meter, a new technology, applied in the field of Weibo consistency meter, can solve the problems of low versatility, low alignment, difficulty in adjusting the axis of the feed port and the container, and the axis of the measuring rod and the container. Adjust the range, improve the versatility, and improve the effect of the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

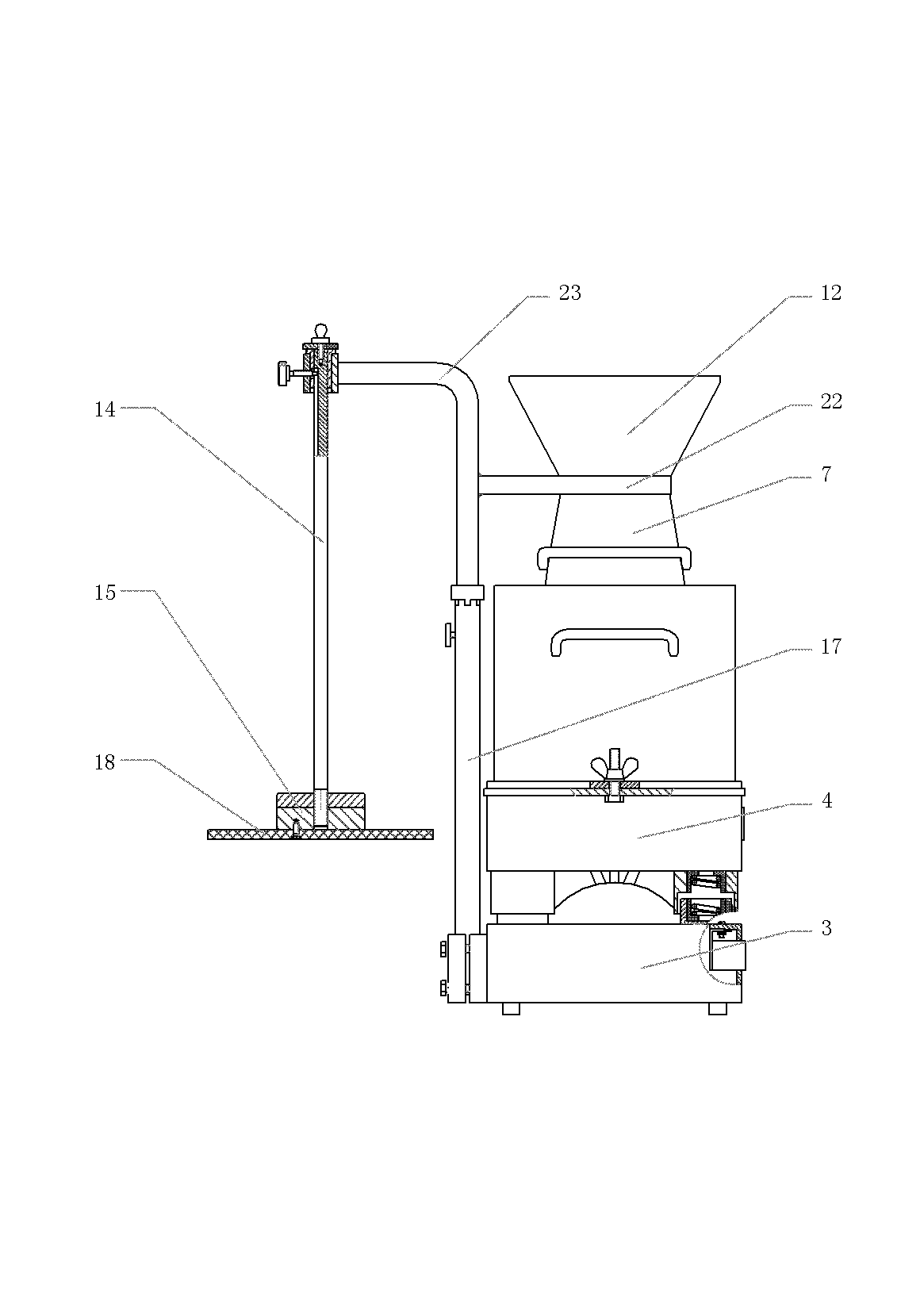

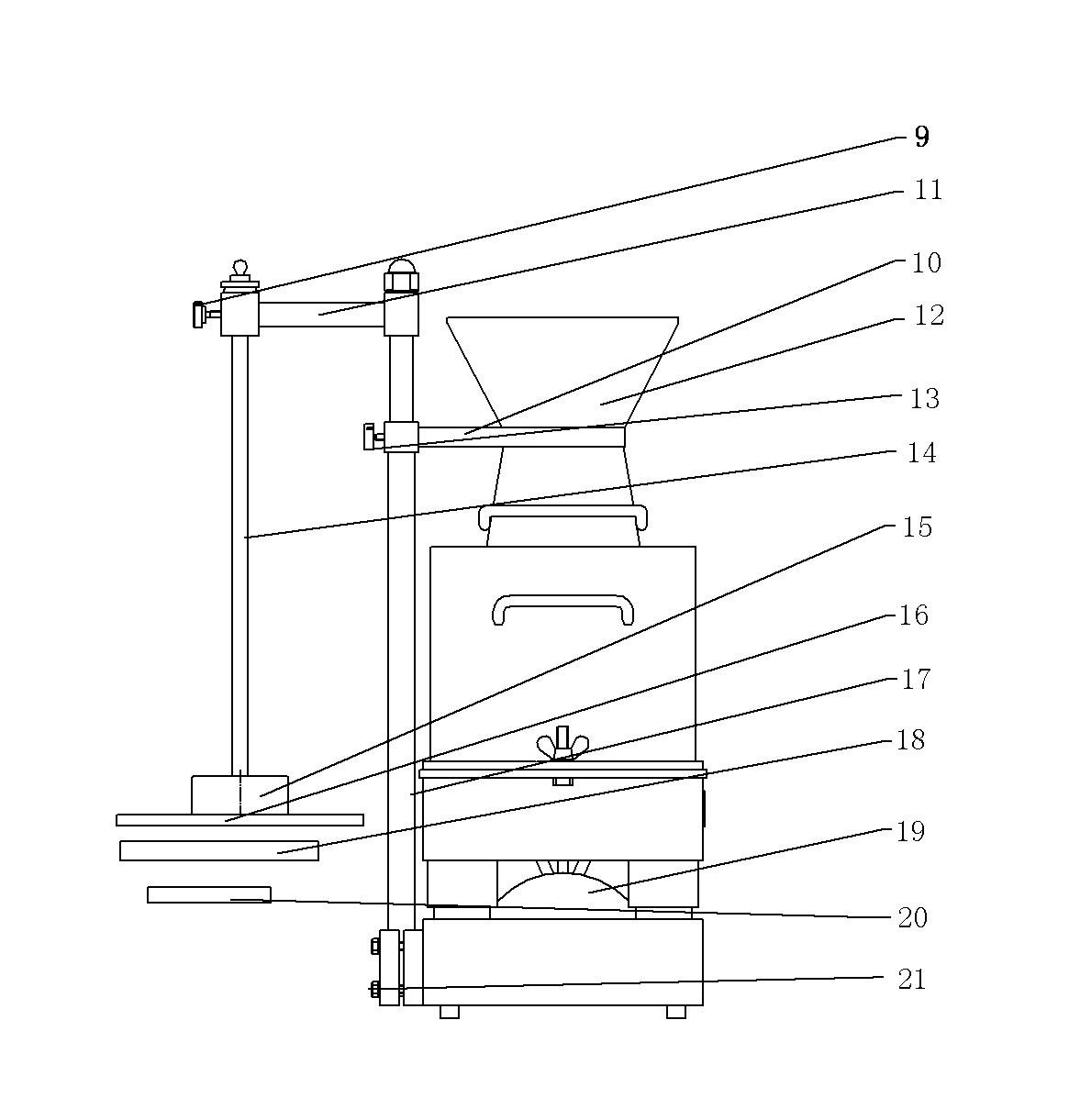

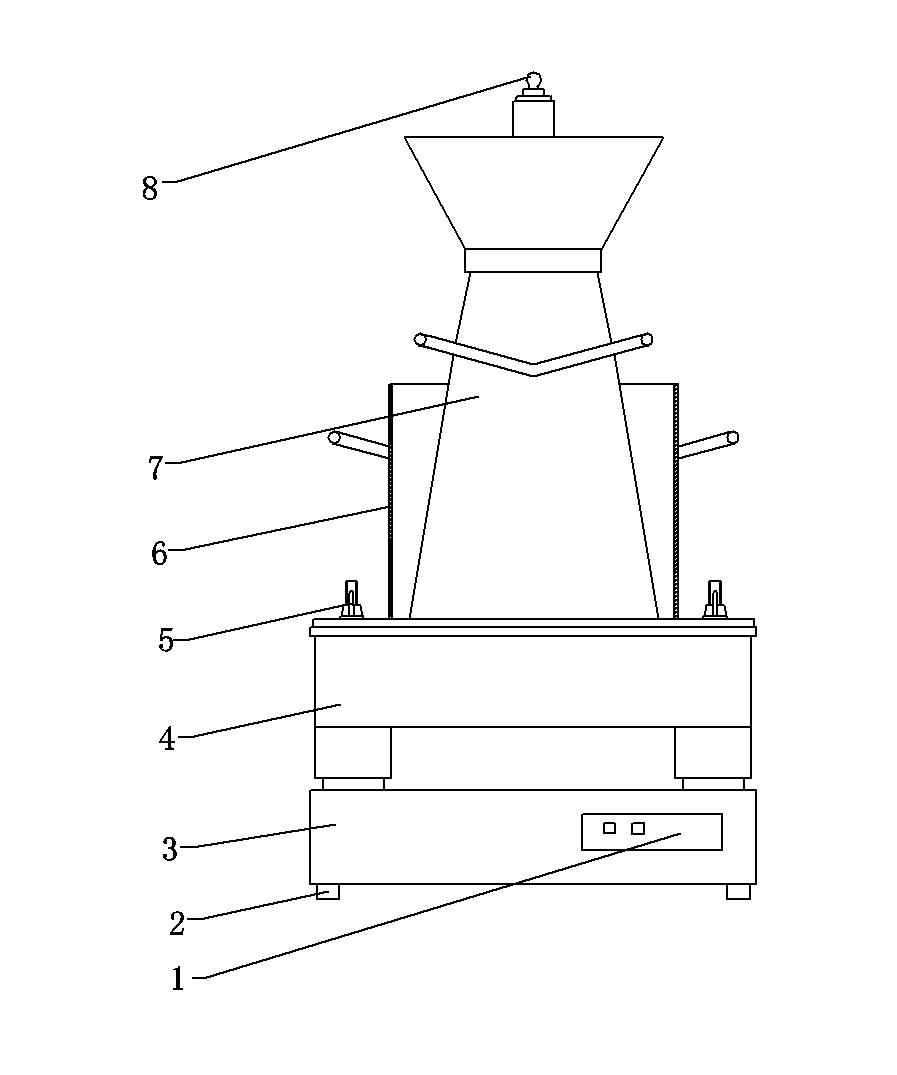

[0010] See figure 2 and image 3 , the present invention includes a slump cylinder 7, the slump cylinder 7 is placed in the container 6, the container 6 is placed on the upper seat 4, the upper seat 4 is installed on the base 3, and the upper part of the slump cylinder 7 is buckled with a feed port 12, The base 3 is fixed with a column 17 by a bolt 21, and the top of the column 17 is equipped with a swivel frame 11, and the lateral end of the swivel frame 11 is equipped with a measuring rod 14, and the bottom of the measuring rod 14 is equipped with a transparent disc 15 and a counterweight. The weight is installed on the bottom of the transparent disc 15, and the rotating frame 11 passes through the fixing screw (the fixing screw is in the figure 2 Blocked by the column 17, invisible) is installed on the top of the column 17, and the horizontal fixed rod 10 of the feed inlet is connected with the column 17 by the fixing screw 13. There are three counterweights, 16, 18 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com