Special MDEA formula solution activated by functional ion liquid for CO2 gas absorption separation

A technology for ionic liquid and gas absorption, applied in separation methods, dispersed particle separation, chemical separation, etc., can solve problems such as corrosion, loss of materials, absorption capacity, and volatilization loss, and achieve high energy consumption, less material loss, and green high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

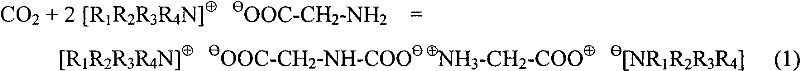

Method used

Image

Examples

Embodiment 1

[0047] 35 grams of N-methyldiethanolamine, 20 grams of triethylbutylammonium L-alaninate ionic liquid, 30 grams of polyethylene glycol dimethyl ether and 15 grams of deionized water were mixed and fully stirred to obtain the present invention MDEA formula absorbent.

Embodiment 2

[0049] 40 grams of N-methyldiethanolamine, 15 grams of triethylbutylammonium glycinate ionic liquid, 25 grams of polyethylene glycol dimethyl ether and 20 grams of deionized water were mixed and fully stirred to obtain the MDEA formulation absorption of the present invention. liquid.

Embodiment 3

[0051] 45 grams of N-methyldiethanolamine, 20 grams of trimethylbutylammonium acetate ionic liquid, 20 grams of sulfolane and 15 grams of deionized water were mixed and fully stirred to obtain the MDEA formula absorption solution of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com