Smoothwall blasting method for digging tunnel

A technology of smooth blasting and tunneling, applied in the field of blasting, which can solve the problems of large damage and disturbance of rock mass, increase of engineering cost, over-excavation, etc., and achieve the effects of saving excavation costs, simple and economical construction, and beneficial to over-excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

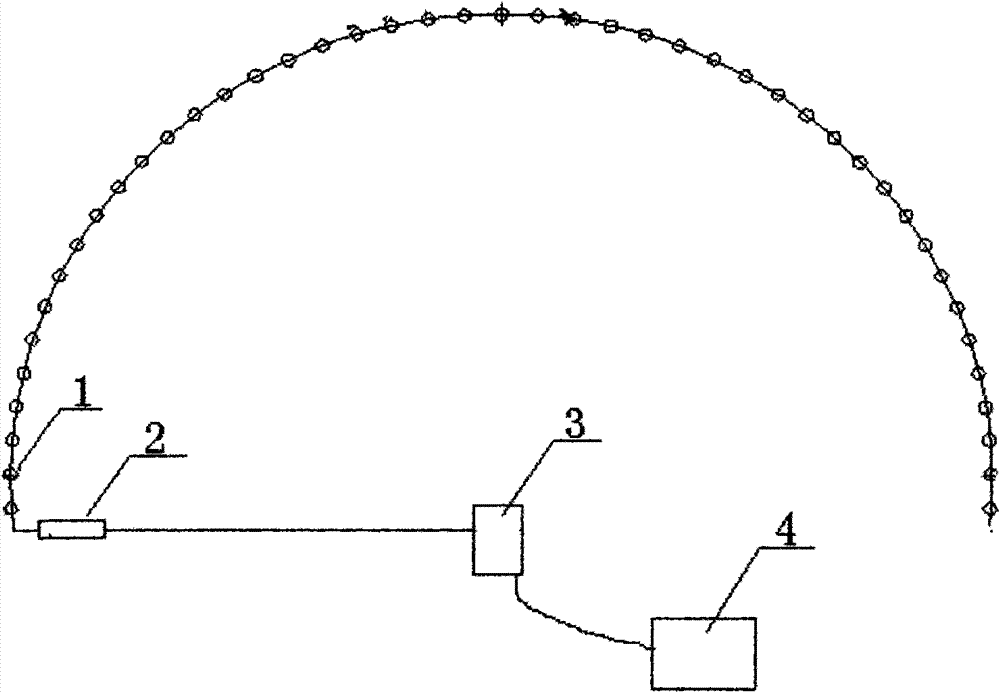

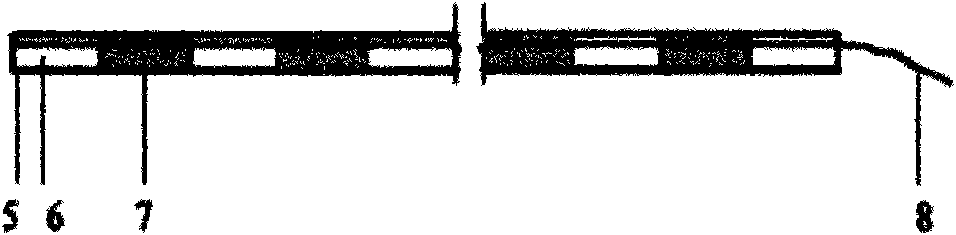

[0024] Excavate a tunnel with an arch height of 5.5 meters, drill in front of the eyes, the surveyors use a total station to accurately determine the center line of the tunnel and the elevation of the vault surface, in order to achieve the best blasting effect, first mark the blasting point 1 on the rock to be excavated, mark The method is: the first layer of the rock is the center layer of the rock, the center layer marks a central blasting point, draws concentric circles with the center blasting point as the center, marks the blasting point 1 on the semicircular arch circle of the ninth layer of the rock, and the same The distance of each blasting point 1 on the arch circle is 35cm, it can be calculated that 45 blasting points are needed, mark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com