Weft storage device and weaving system

A technology of weft storage and driving device, which is applied in textile, loom, textile and paper making, etc., can solve the problem of large damage of weft yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

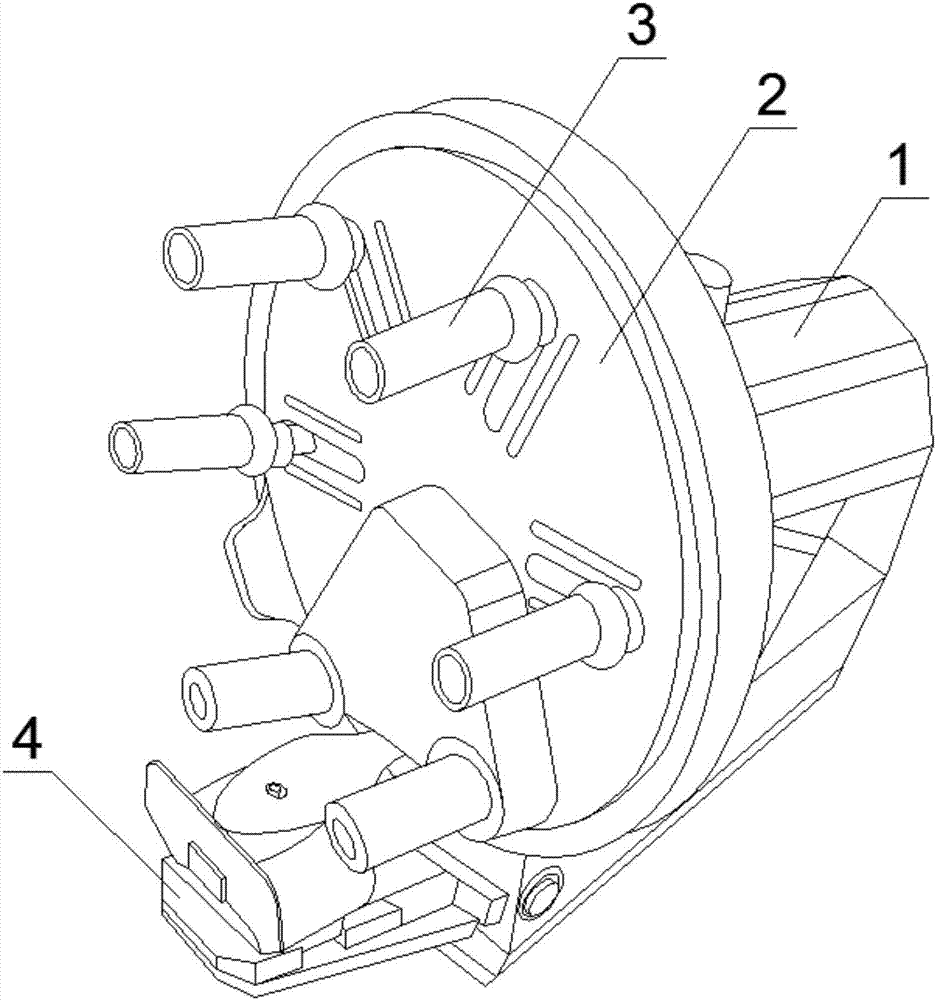

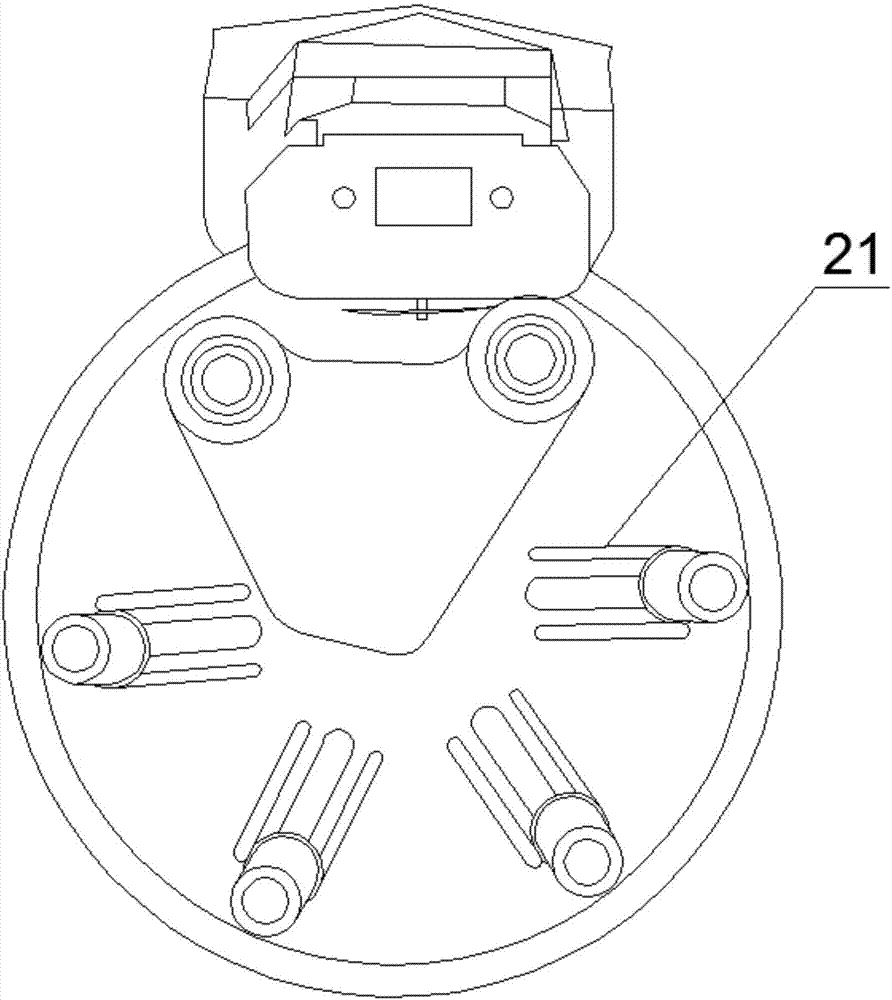

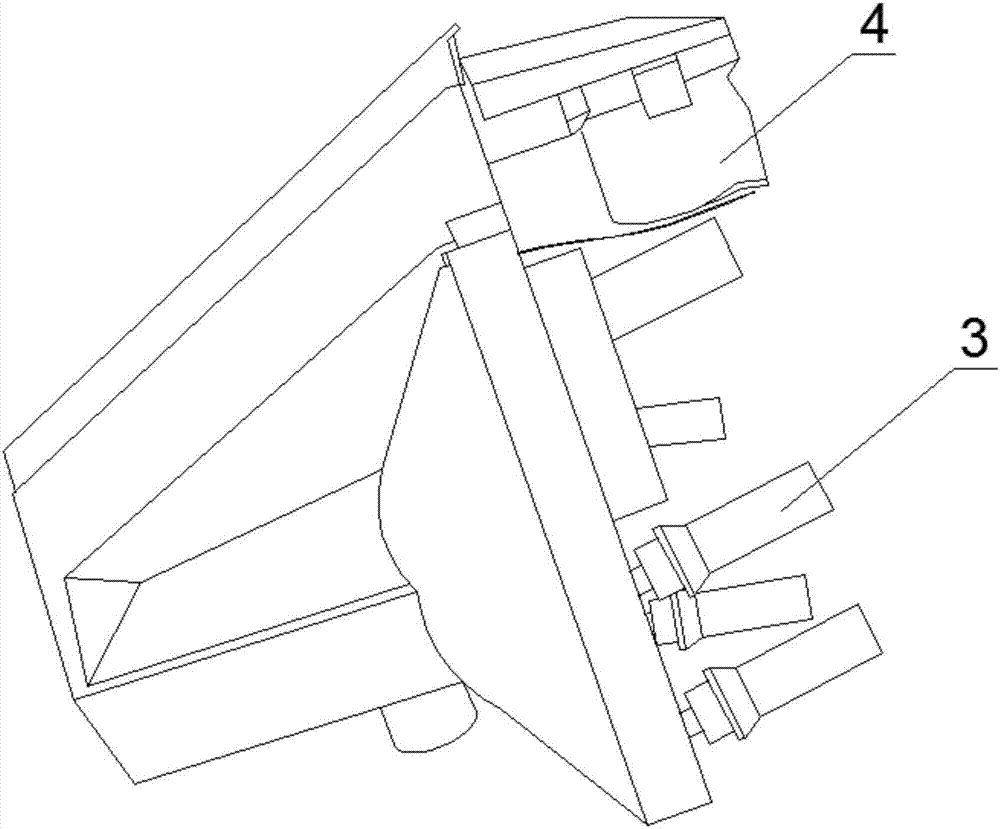

[0053] In the optional scheme of this embodiment, such as Figure 1 to Figure 4 As shown, a weft storage device provided in this embodiment includes a housing 1, a driving device, a yarn winding disc 2, a yarn winding guide roller 3 and an electromagnetic control device 4; Above; the first end of the yarn winding guide roller 3 is set on the yarn winding disc 2, the second end of the yarn winding guide roller 3 is free, and the yarn winding guide roller 3 can rotate around its first end at a fixed point; the driving device is arranged on the housing 1, used to drive the yarn winding disk 2 to rotate; the electromagnetic control device 4 is arranged on the housing 1, and is located in the radial direction of the yarn winding disk 2, and is used to control whether to put weft or not.

[0054] In this embodiment, the yarn winding disc 2 is fixedly rotated on the housing 1 and can rotate on the housing 1; one end of the yarn winding guide roller 3 is set on the yarn winding disc 2...

Embodiment 2

[0074] In an optional solution of this embodiment, a weft storage device provided by this embodiment includes a housing 1, a driving device, a winding disk 2, a winding guide roller 3 and an electromagnetic control device 4; The shaft rotation is set on the housing 1; the first end of the yarn winding guide roller 3 is arranged on the yarn winding disk 2, the second end of the yarn winding guide roller 3 is free, and the yarn winding guide roller 3 can rotate around its first end at a fixed point The driving device is arranged in the casing 1 for driving the rotation of the yarn winding disk 2; the electromagnetic control device 4 is arranged on the casing 1 and is located in the radial direction of the yarn winding disk 2 for controlling whether to put weft.

[0075] In this embodiment, since the included angle between the yarn winding guide roller 3 and the yarn winding disc 2 is adjustable, the tension of the yarn winding is adjustable when winding the yarn, and the degree o...

Embodiment 3

[0086] In an optional solution of this embodiment, a weaving system provided by this embodiment includes the weft storage device as described in Embodiment 1 or Embodiment 2.

[0087] In this embodiment, the weft storage device can efficiently perform weft supply, weft storage, and fixed-length weft release, and the yarn winding tension is adjustable. The greater the damage to the weft yarn, the greater the degree of damage to the weft yarn. Flat, the dyed cloth is evenly colored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com