PETG (Polyethylene Terephthalate Glycol) printing sheet for RFID (radio frequency identification device) label and manufacture process thereof

A technology of RFID tags and sheets, applied in the field of polyester resin, can solve problems affecting product quality and output, difficult to obtain wetting tension, and difficulty in stacking, so as to reduce production costs, meet process defoaming requirements, and produce finished products high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

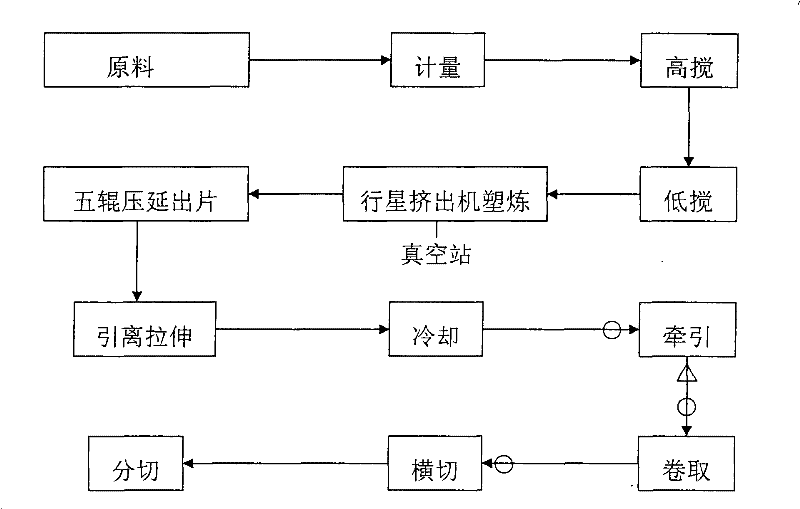

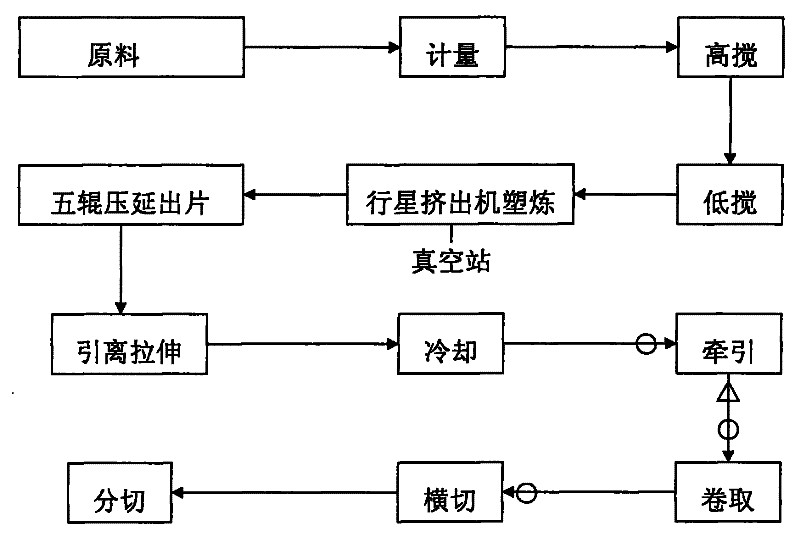

Method used

Image

Examples

Embodiment 1

[0054] Recipe: 100 GS 2 Type PETG resin, 10 parts ADD 2 Type PETG resin, 15 parts of rutile RFC5 type titanium dioxide, 15 parts of nano calcium carbonate (CaCO 3 ) SP-100, 5 parts of UV absorber 3039, 8 parts of antioxidant 168, 2 parts of lubricant WAX-E, 0.03 parts of antistatic agent HS1.

[0055] Manufacturing process:

[0056] a. Raw material preparation: Weigh the raw material according to the formula, crush the PETG raw material to 40 mesh, and dry it;

[0057] b. High-speed stirring: the raw materials are heated and melted, the temperature is controlled at 102°C, the first speed of high stirring is controlled at 900 rpm, stirring for 10 minutes, the second speed of high stirring is controlled at 1800 rpm, stirring for 3 minutes, and the third speed of high stirring is controlled At 900 rpm, stir for 10 minutes;

[0058] c. Stirring at low speed: the temperature is controlled at 53°C, stirring at 80 rpm, and the stirring time is 15 minutes;

[0059] d. Planetary e...

Embodiment 2

[0067] Recipe: 100 GS 2 Type PETG resin, 13 parts ADD 2 Type PETG resin, 12 parts of rutile RFC5 type titanium dioxide, 12 parts of nano calcium carbonate (CaCO 3 )SP-100.

[0068] Manufacturing process:

[0069] a. Raw material preparation: Weigh the raw material according to the formula, crush the PETG raw material to 50 mesh, and dry it;

[0070] b. High-speed stirring: the raw materials are heated and melted, the temperature is controlled at 100°C, the first speed of high stirring is controlled at 900 rpm, stirring for 12 minutes, the second speed of high stirring is controlled at 1700 rpm, stirring for 5 minutes, and the third speed of high stirring is controlled At 900 rpm, stir for 10 minutes;

[0071] c. Stirring at low speed: the temperature is controlled at 50°C, stirring at 70 rpm, and the stirring time is 20 minutes;

[0072] d. Planetary exhaust extruder plastication: the temperature is controlled at 180°C, and at the same time, a vacuum station is used for v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com