Electric positioning impact wedging machine

An electric positioning and impact technology, applied in the field of die forging hammers in the mechanical field, can solve the problems of occupation, large hammer, large workshop area, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

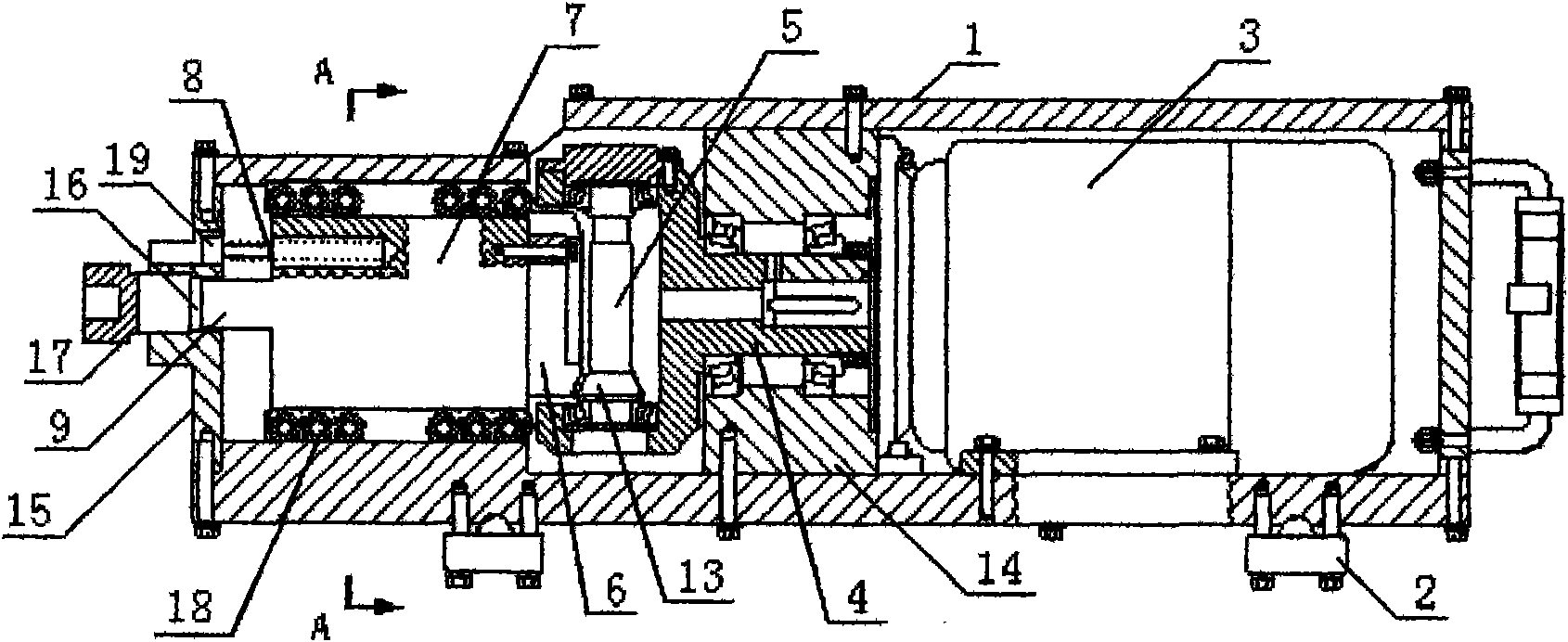

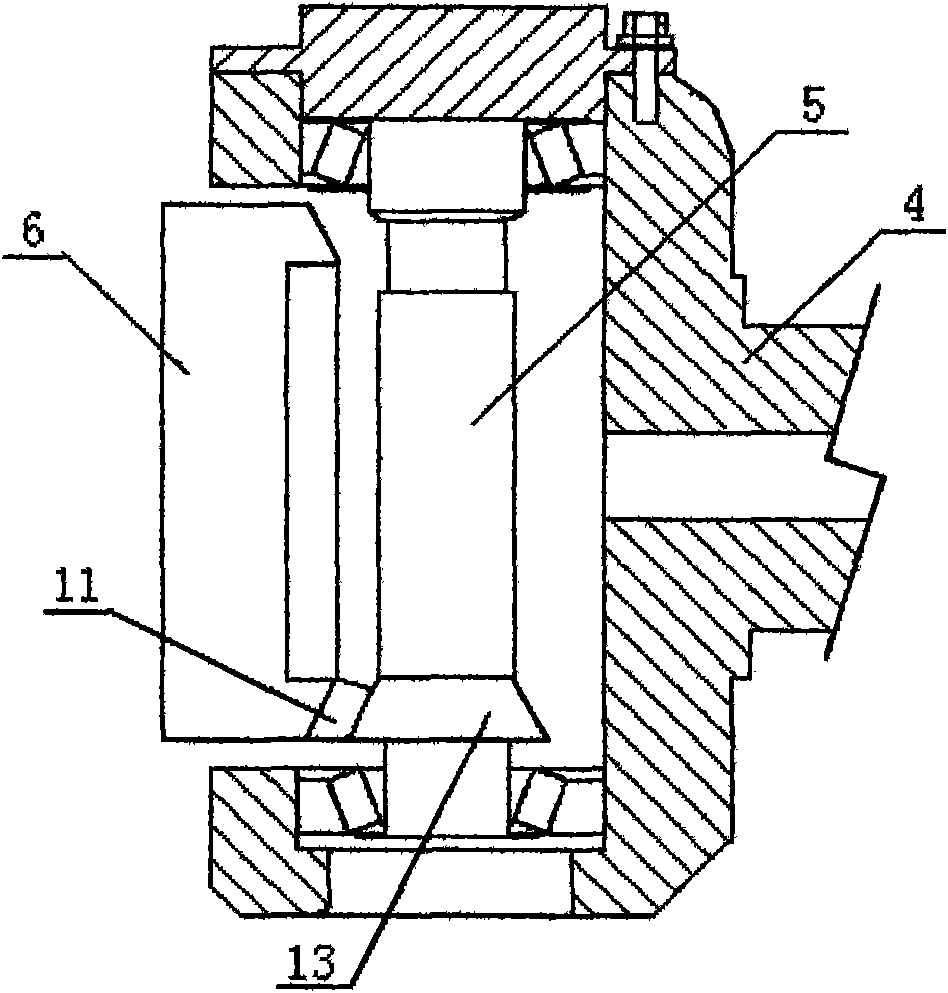

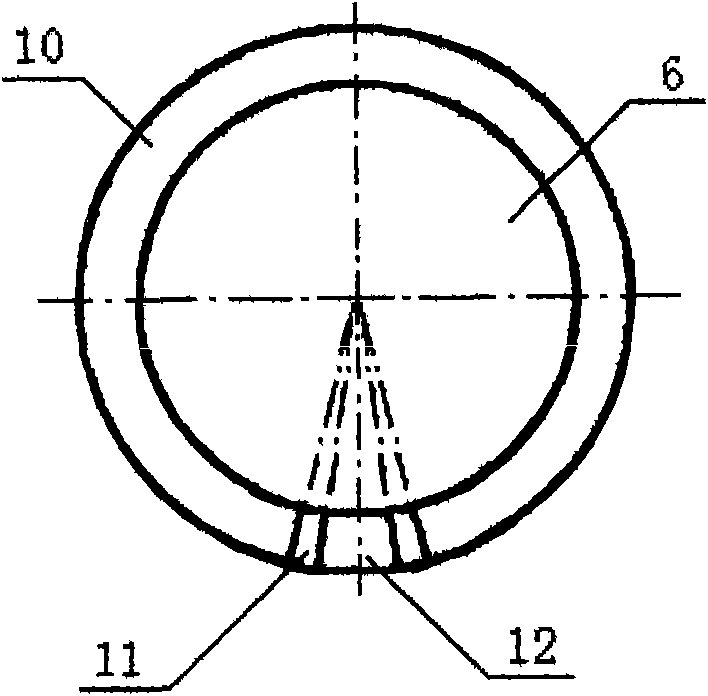

[0020] Such as Figure 1 to Figure 5 As shown, an electric positioning impact type wedge tightening machine is composed of a body 1, an impact mechanism, and a hoisting mechanism 2. The body 1 has a hoisting mechanism 2, and the body 1 has an impact mechanism. The impact mechanism consists of a motor 3, a pulley frame 4, The pulley shaft 5, the plane cam 6, the impact iron block 7, and the return spring 8 are composed of one end surface of the plane cam 6 with a smoothly connected in-situ conical surface 10, a spiral conical surface 11, and a raised conical surface 12, forming a continuous curved surface , the convex conical surface 12 is 5-10mm higher than the in-situ conical surface 10 in the axial direction, the angle of the spiral conical surface 11 on the end face circumference of the plane cam 6 is 9-18°, and the pulley shaft 5 is on the plane cam 6 The conical frustum 13 whose continuous curved surface angle matches, the pulley shaft 5 is connected with the pulley frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com