Tool for making microstructured articles

A microstructured and structured technology, applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of difficult, expensive, and increase the overall cost of microstructured graphics, reducing pre-preparation time, Easy and fast changing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

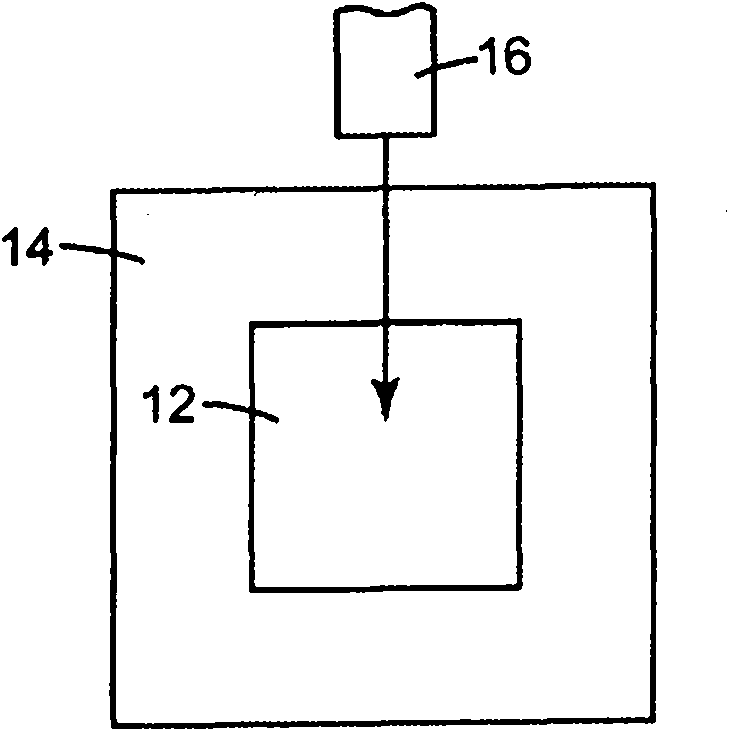

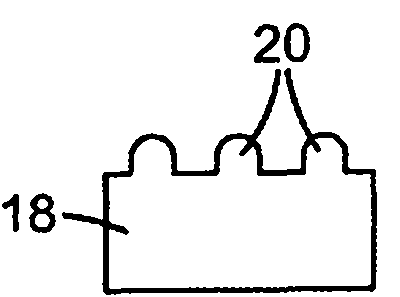

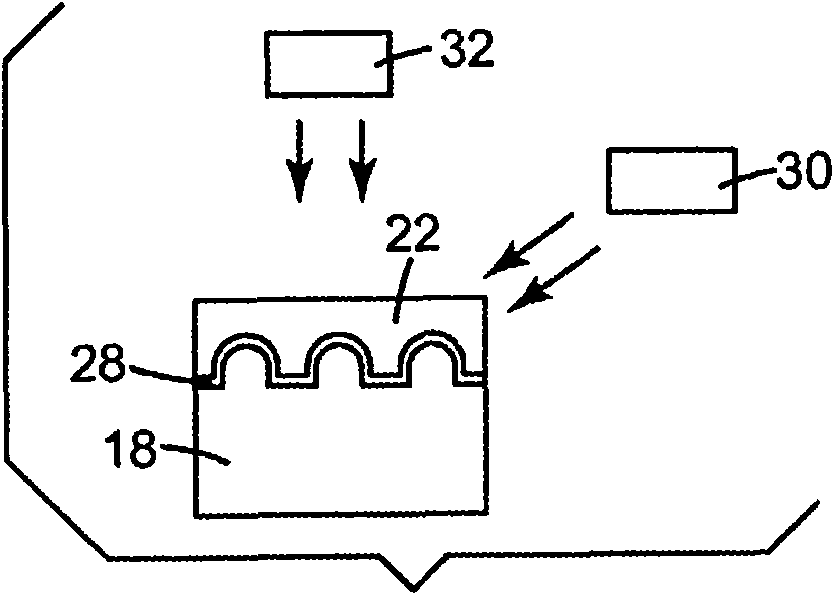

[0017] The present invention relates to a method for the preparation of replication tools which can then be used for the preparation of microstructured articles. As noted above, microstructured articles have microstructured surface features having structures (protrusions, depressions, grooves, etc.) on their surface that are microstructures in at least two dimensions. As used herein, the term microscopic refers to dimensions that are indistinguishable to the human eye without the aid of a microscope. A usable resolution of the microscopic exists as described by Smith in Modern Optic Engineering, (1966), pages 104-105 (Modern Optical Engineering (1966), pp. 104-105), where visual acuity is defined and expressed as Measured by the corner size of the smallest recognizable character. Normal visual acuity allows the detection of characters subtending an elevation angle of 5 minutes of arc on the retina. In some cases, the dimensions of the microstructures are less than 1000 micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com