Method for controlling a crane

A technology of cranes and machinery, which is applied in the direction of clockwork mechanism, load hanging components, hoisting device, etc., which can solve the problems of short service life of ropes and achieve the effect of prolonging and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

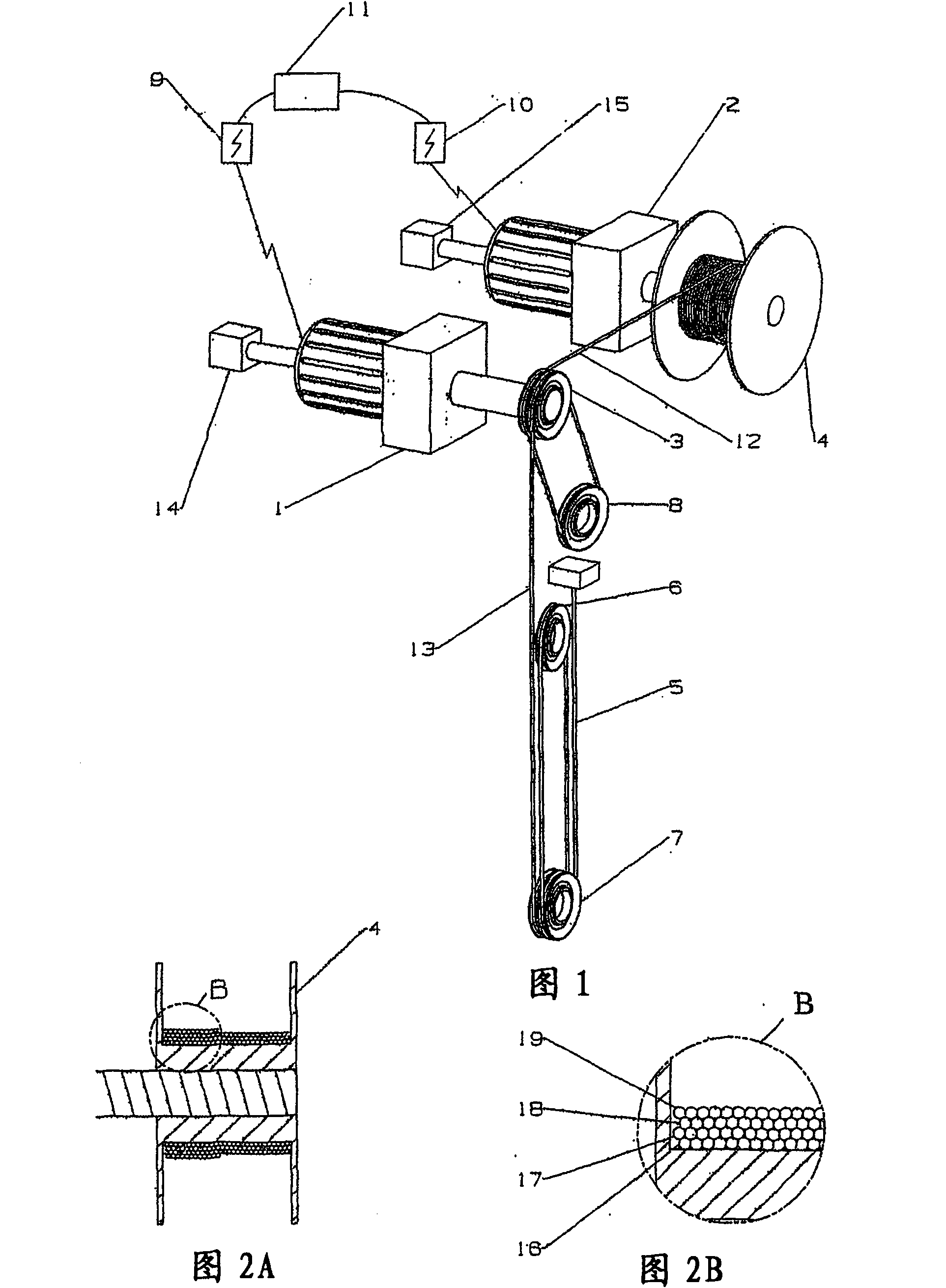

[0015] figure 1 The structure of the crane used in the method of the invention is shown in more detail. Part 1 and Part 2 are mechanical devices. The mechanical part 1 is driven by an electric drive 9 and the mechanical part 2 by an electric drive 10 . The electric drive is usually a variable frequency drive, but a similar invention can also be realized with a DC drive. The mechanism 1 drives the friction drive wheel 3 and the mechanism 2 drives the storage reel 4 . Pulley 8 is used to obtain a large enough rope grip angle. Increasing the grip angle increases friction. The pulley system 6 and 7 constitutes a conventional rope drive for reducing the required rope force. The hook of the crane (not shown) is fastened to the lower pulley system 7 . The rope portion 5 is fastened to a fixed point of the crane superstructure. The shaft of the mechanism includes angle sensors 14 and 15 which provide velocity and position information of the mechanism. In particular, location i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com