Universal expansion board clamping and pressing element

An expansion board and universal technology, which is applied in the field of universal expansion board pressing parts, can solve the problems of design difficulties, understanding of board size and size, etc., and achieve the effect of simple structure, convenient operation and use, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

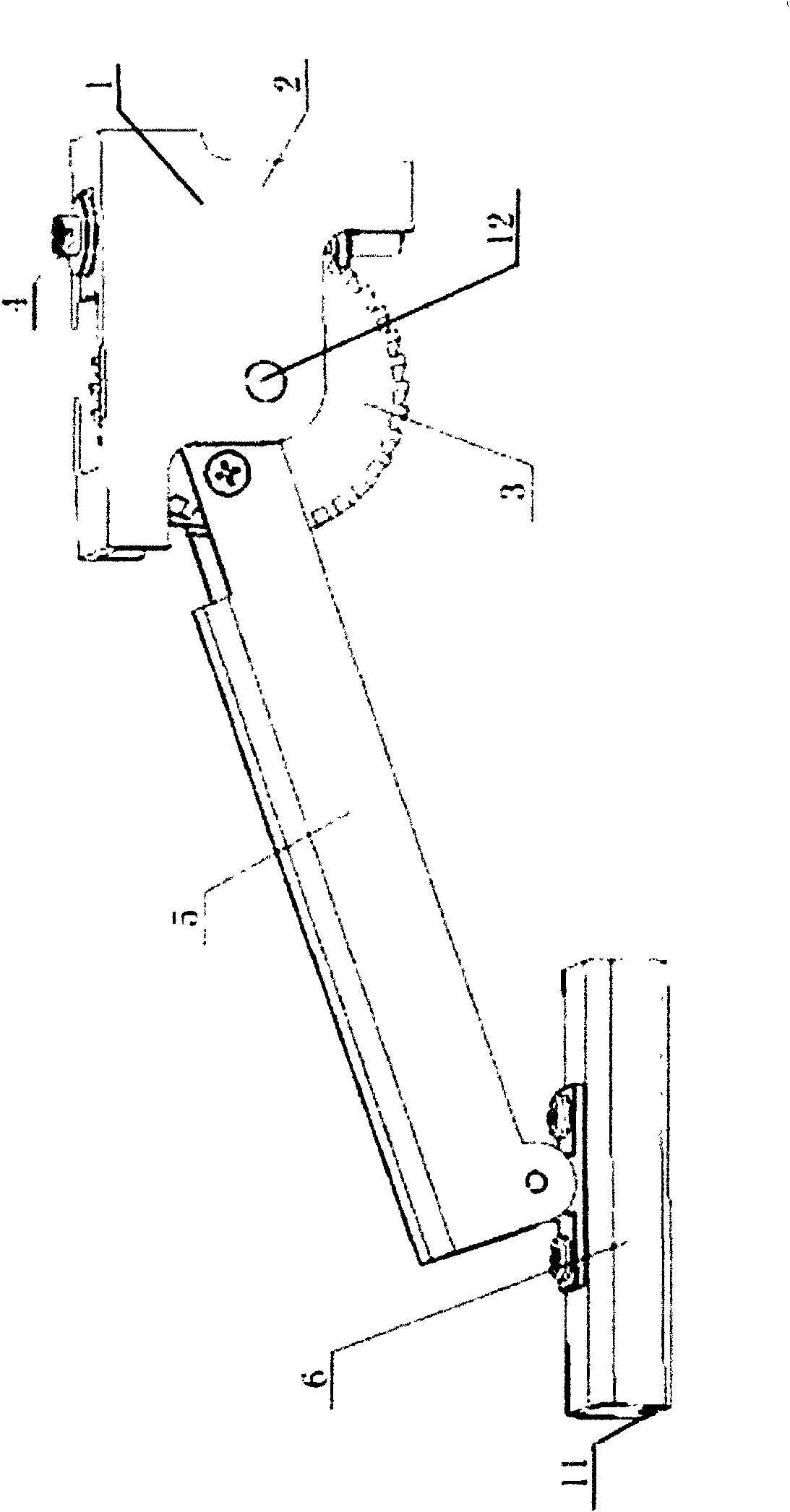

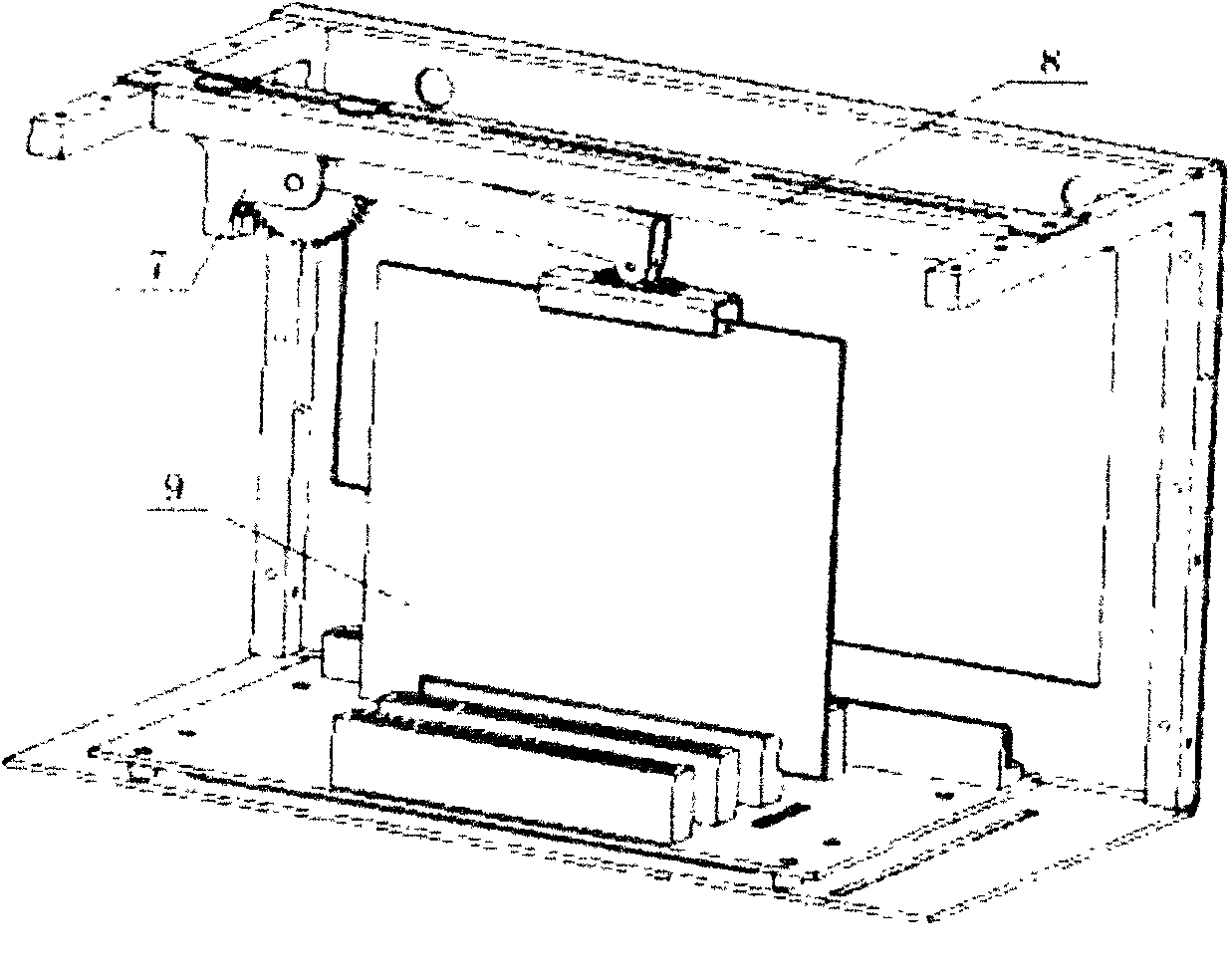

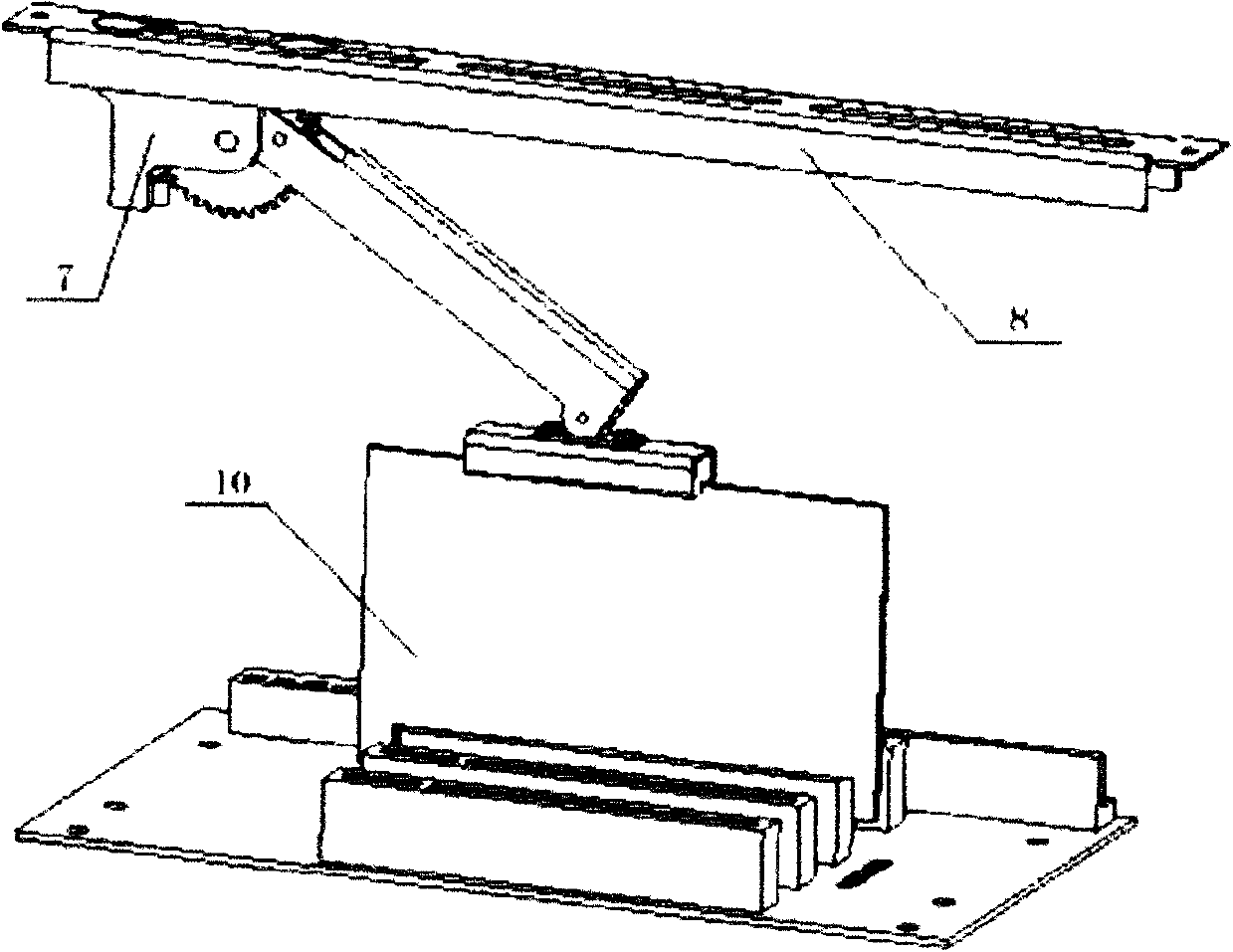

[0027] The structure of the universal expansion board pressing member of the present invention includes a worm gear mechanism 1, a connecting rod 5 and a board pressing block 6, the worm gear mechanism 1 is connected to one end of the connecting rod 5, and the other end of the connecting rod 5 is connected to the board pressing block 6, The worm gear mechanism 1 drives the connecting rod 5 and presses the pressing block 6; the worm gear mechanism 1 includes a base 2, a worm gear 3 and a worm 4, the worm gear 4 is fixed on the base 2, and the worm gear 3 is arranged on the base 2 through a bearing 12 Above, the worm wheel 3 is matched with the worm screw 4, and the connecting rod 5 is inlaid and fixed on both sides of the worm wheel 3.

[0028] There is a rubber presser foot groove 11 at the bottom of the board pressing block 6 .

[0029] The worm gear mechanism 1 drives and exerts force on the connecting rod 5, and the connecting rod 5 is vertically pressed against the board p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com