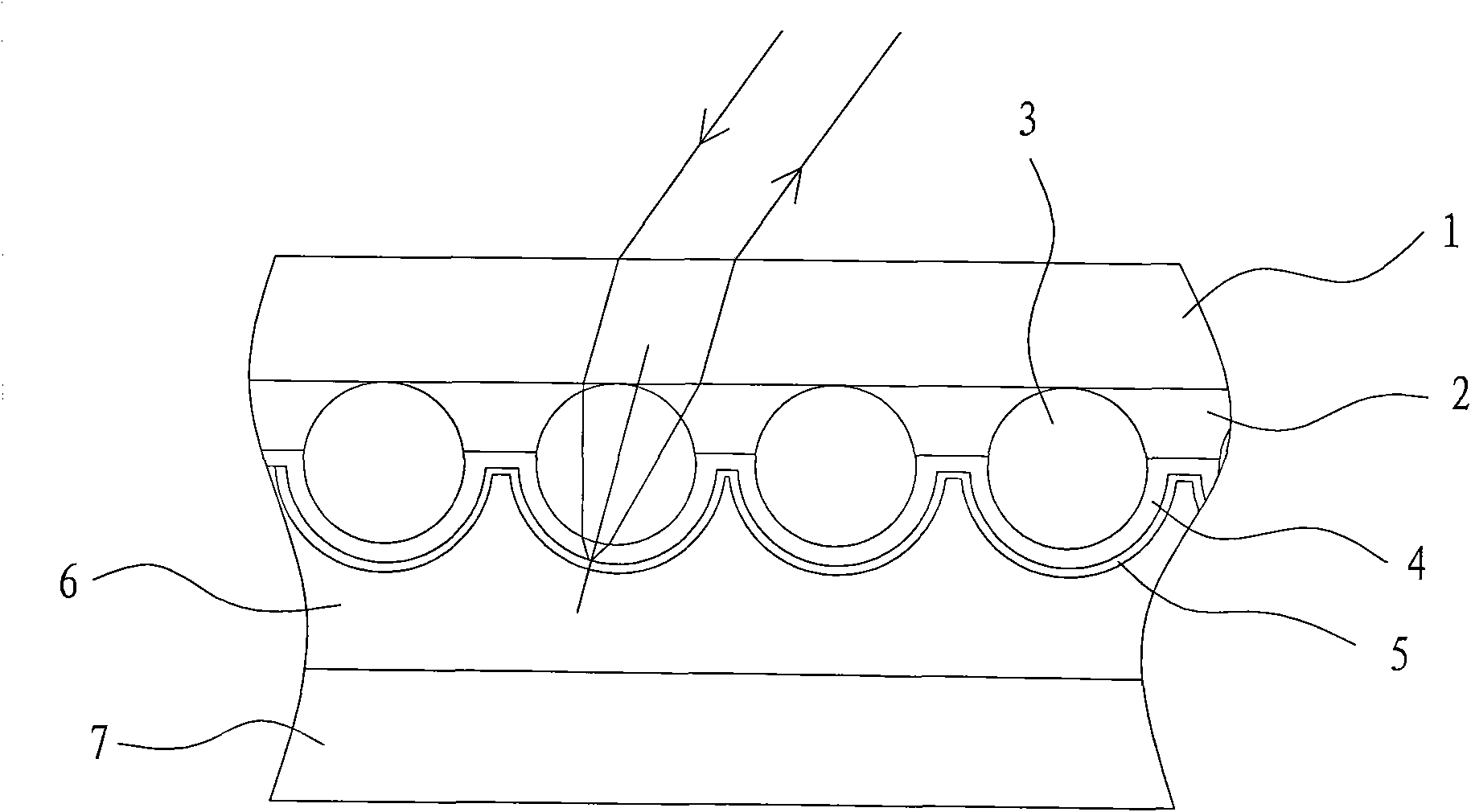

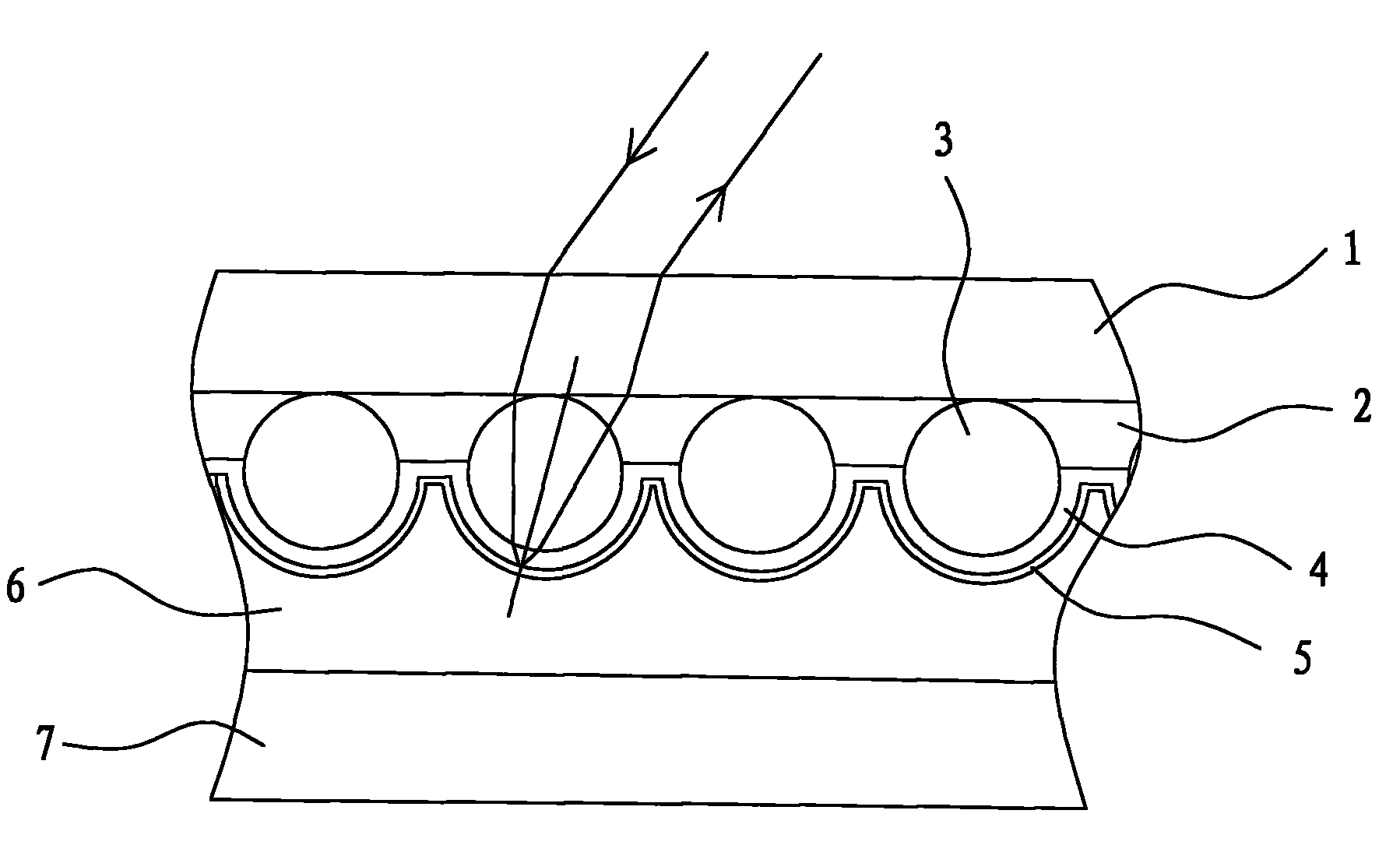

Preparation method of oriented reflective membrane surface material

A technology of surface material and reflective film, applied in optics, optical components, instruments, etc., can solve the problems of high cost and insufficient physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiment discloses a method for preparing a surface layer material of a directional reflective film, comprising the following steps:

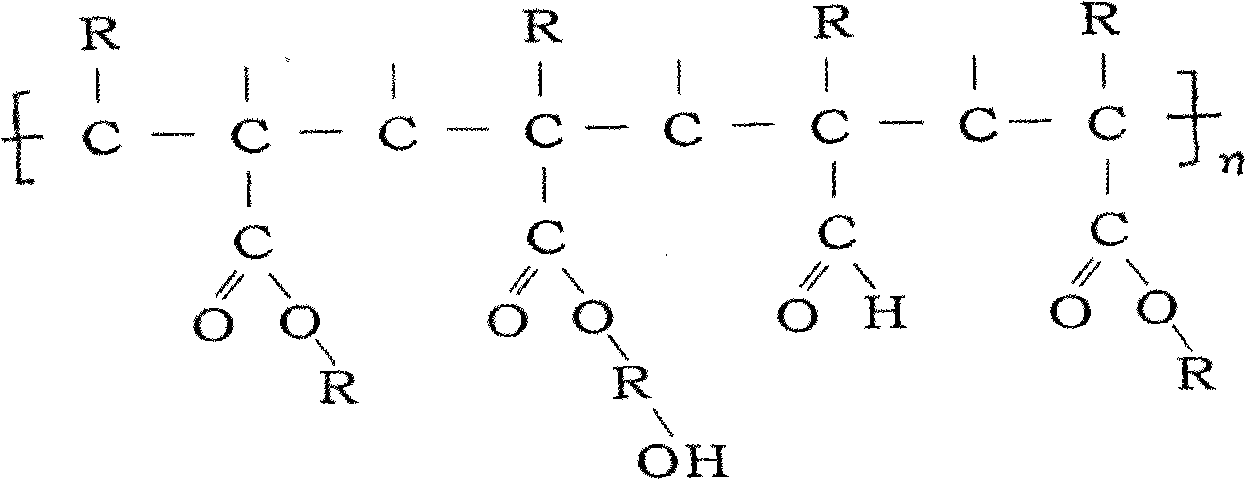

[0042] 1. Preparation of hard acrylic resin:

[0043] a), the following components are prepared according to the corresponding percentages by weight, and the xylene and butyl acetate are mixed to obtain a solvent mixture, and 4 / 5 parts by weight of the solvent mixture are placed in the reaction still, and heat the solvent mixture in the reaction kettle to 120°C and keep stirring; the reaction kettle involved in this step is a common chemical equipment, which has a stirring function and a heating function, and is well known to those skilled in the art. Equipment, 4 / 5 parts by weight is relative to the total amount of dimethylbenzene and butyl acetate in this step. As for the heating temperature, the experimental results show that there is no obvious impact on the finished product within the range of 120 °C plus or minus 5 °C. , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com