Valve mechanism of switch cabinet

A technology for switch cabinets and valves, which is applied in the direction of pull-out switch cabinets, switch devices, guard plates/protection devices of switch devices, etc., and can solve the problem of reduced service life of switch cabinet valve mechanisms, reduced service life of ropes, and increased rope loads, etc. problems, to achieve the effect of improving the service life, reducing the rope load and preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

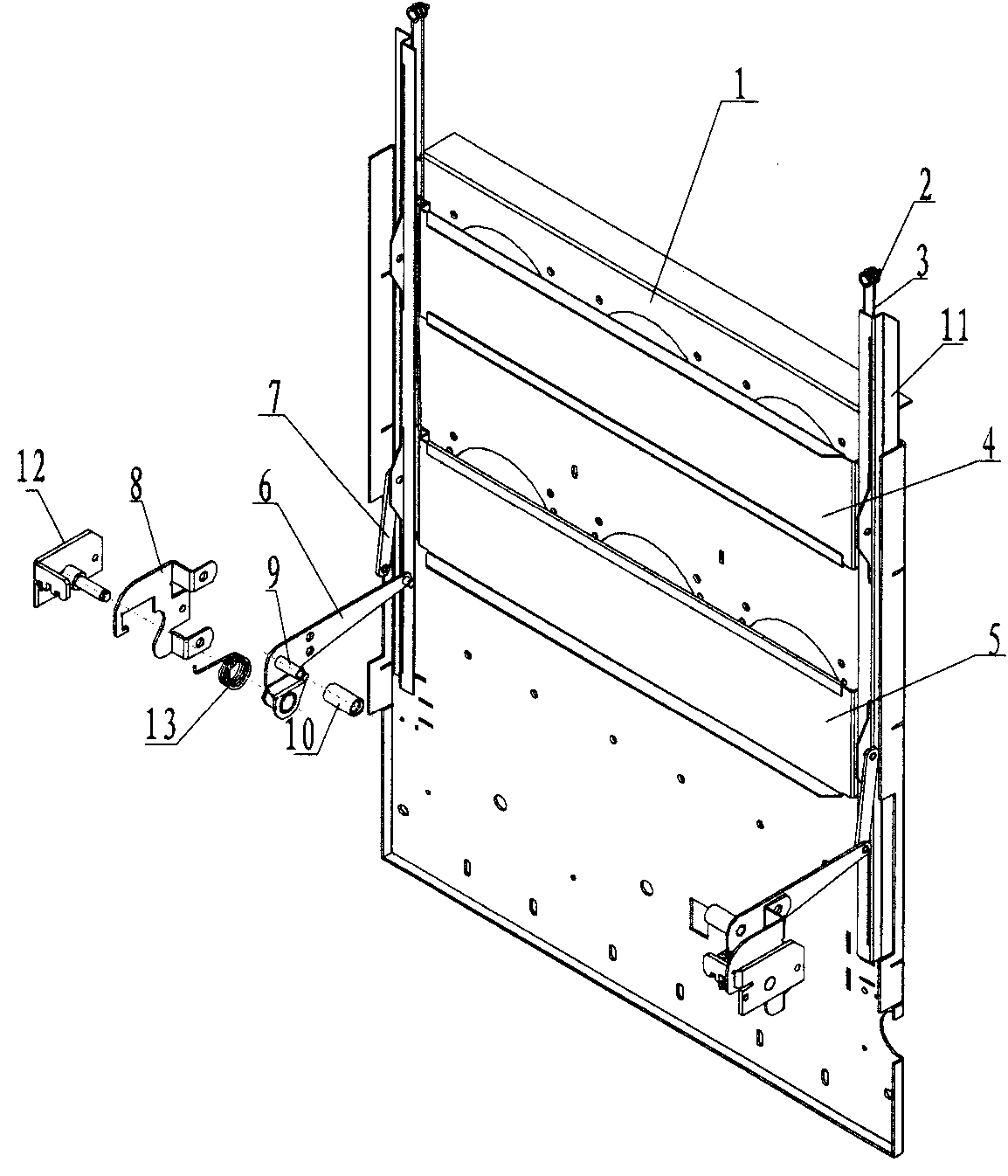

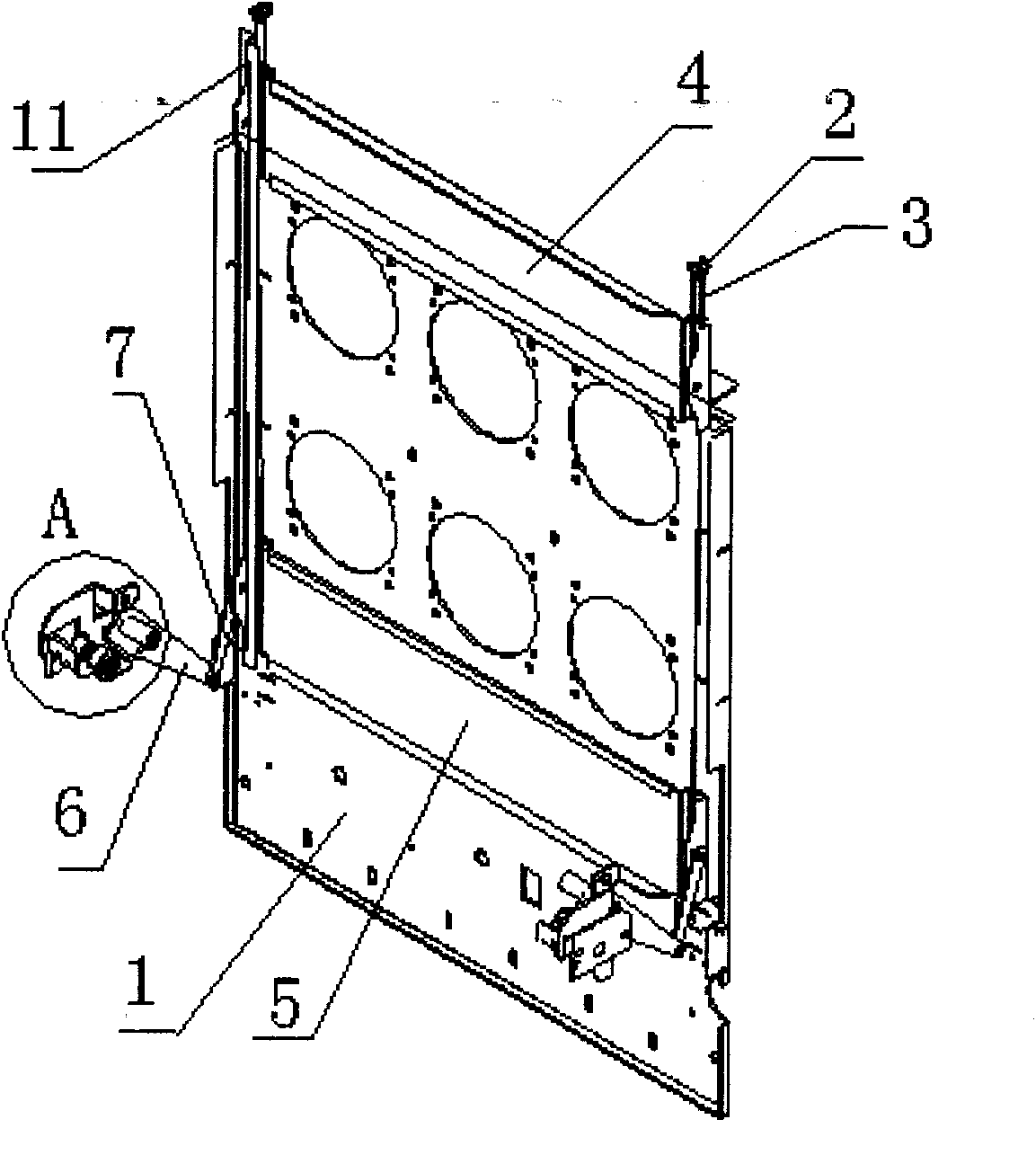

[0031] Such as Figure 1 to Figure 4 As shown, a switchgear valve mechanism of this embodiment includes a middle partition 1, and upper and lower contact box holes are formed on the middle partition 1;

[0032] Fixed pulley 2, the fixed pulley 2 is provided with two, respectively fixed on the cabinet above the left and right sides of the middle partition 1;

[0033] Rope 3, said rope 3 is provided with two, respectively wound on the corresponding said fixed pulley 2;

[0034] Upper and lower valves, one end of the same side of the upper valve 4 and the lower valve 5 is respectively arranged on the two ends of the same side of the rope 3, and the upper valve 4 and the lower valve 5 are wound on the fixed pulley The up and down movement of the rope 3 on the 2 drives the movement of the upper valve 4 and the lower valve 5 so as to realize the opening and closing of the upper and lower contact box holes;

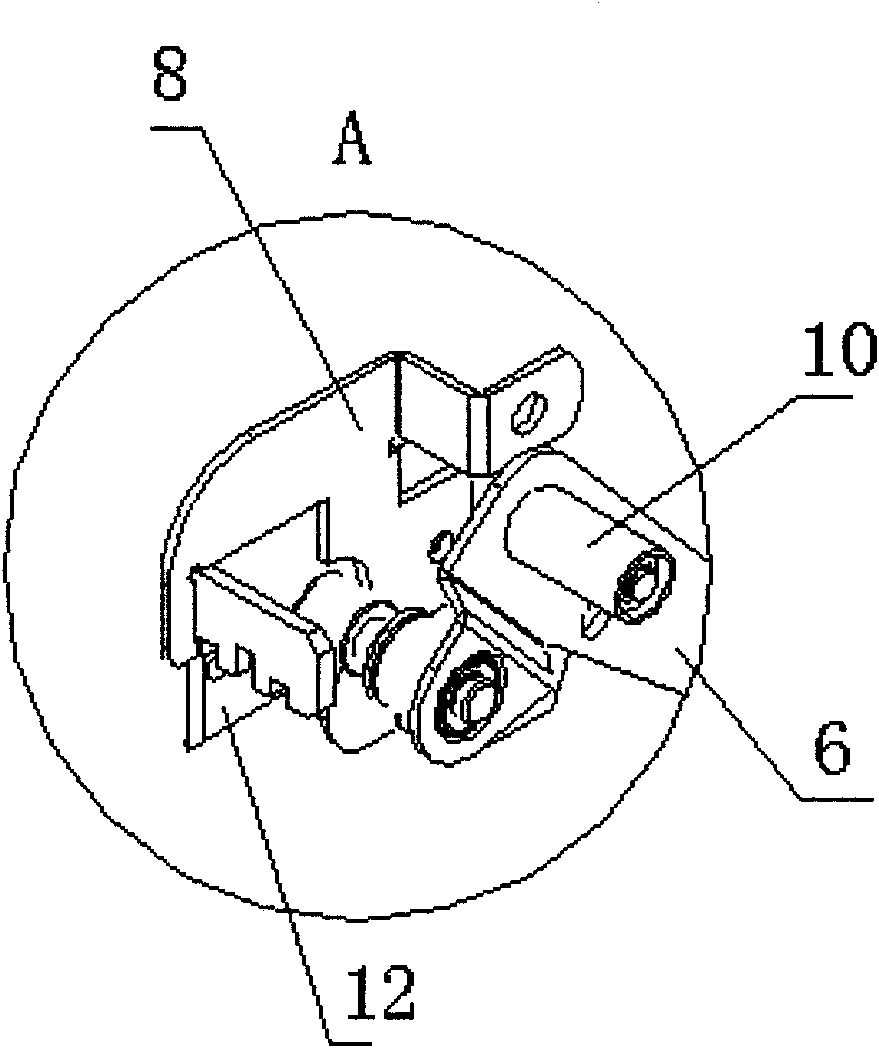

[0035] The lower valve operating mechanism, the lower valve operating mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com