Phase-changing and temperature-regulating blended yarn and production process thereof

A production process and blended yarn technology, which is applied in the field of textile production, can solve the problems such as the difficulty of phase-change temperature-adjusting fiber yarn formation, and achieve the effects of improving the difficulty of yarn formation, improving wearability, and poor air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

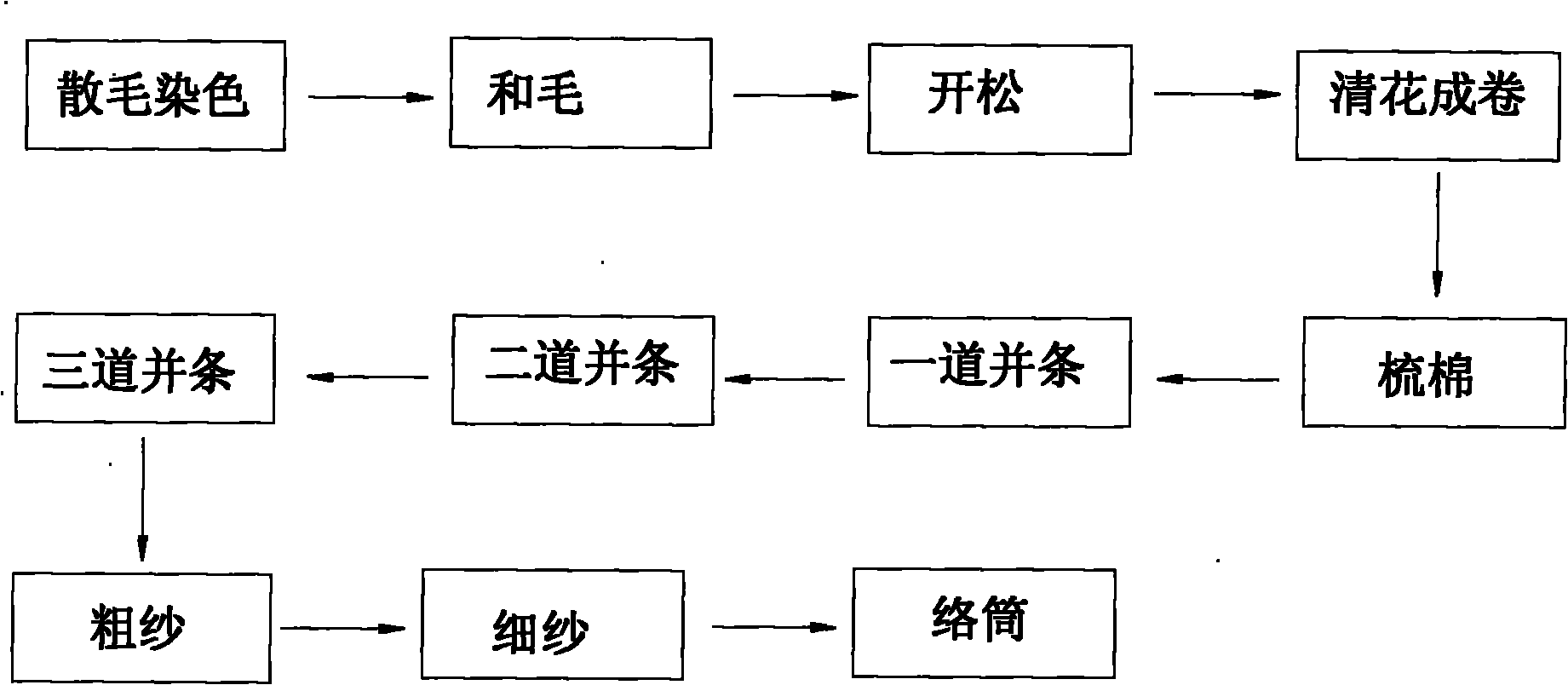

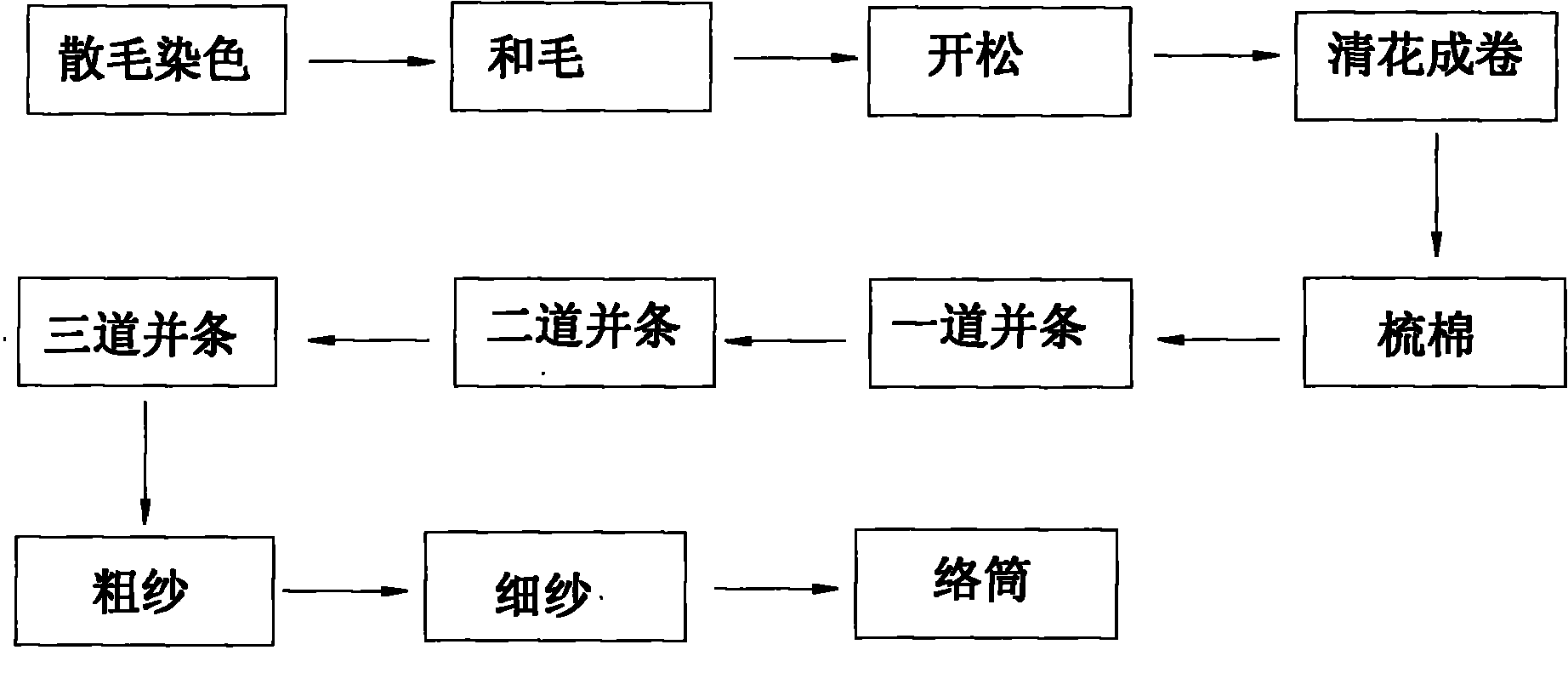

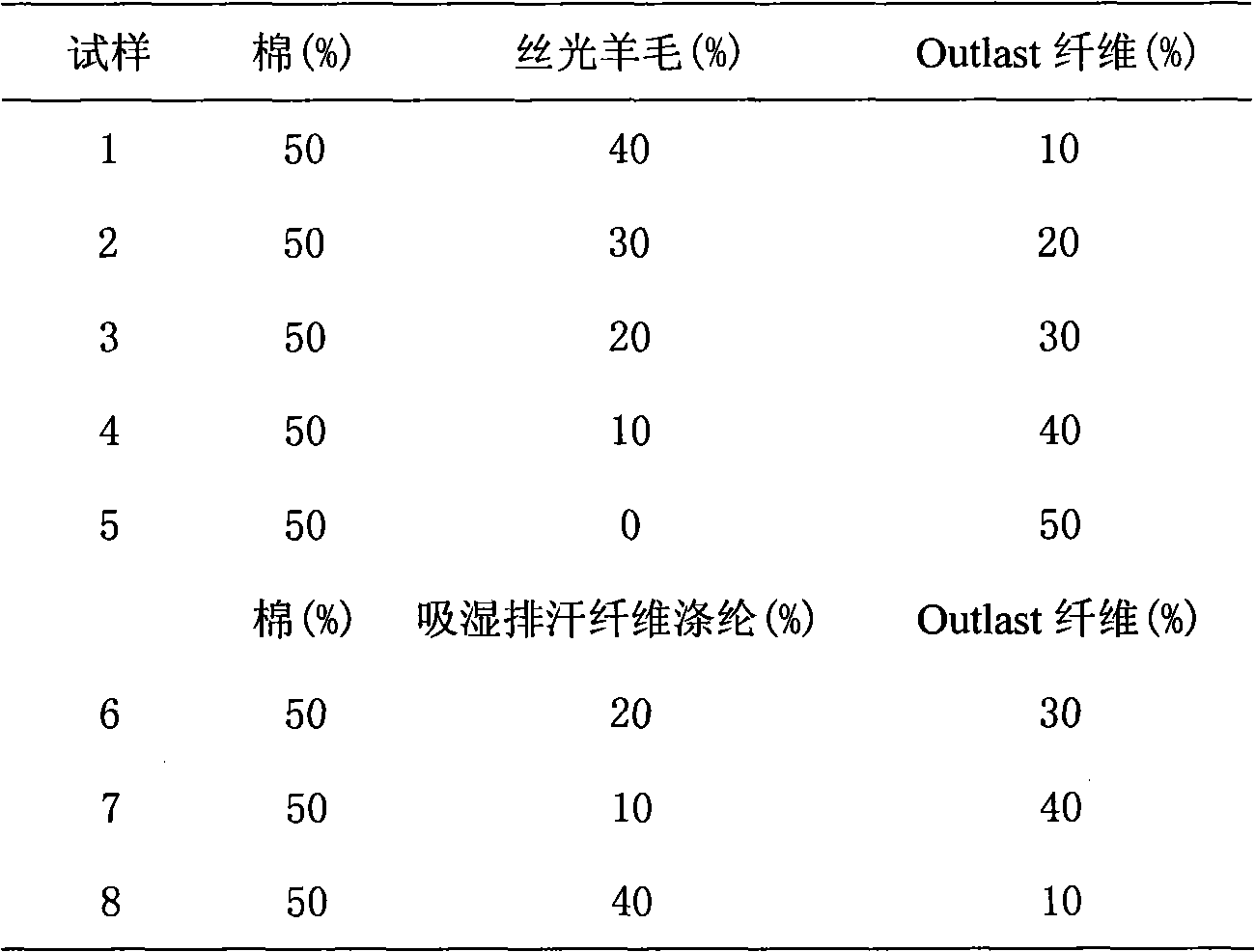

[0028] Cotton, mercerized wool, Outlast fiber, and moisture-absorbing and sweat-wicking fiber are blended, and the structure and performance of each fiber raw material are greatly different. In order to achieve the required blended yarn quality, the present invention uses a semi-worsted wool spinning system for spinning. Its basic process mode is: woolen and woolen equipment in the front, carding frame and draw frame for cotton spinning, roving frame for wool spinning, spinning frame for cotton spinning, and winding, doubling and two-for-one twisting equipment for worsted spinning in the rear . Semi-worsted blends have the finish of worsted wool and the bulk of carded wool. The process flow is as follows (equipment models used are in brackets):

[0029] Dyeing of loose wool → and wool (BC262) → loosening (FA100) → cleaning and coiling (A035C; FA046; A176E; A045B combination) → carding (A186H) → one-stage drawing (FA304) → two-stage drawing (FA304 )→three-way drawing (FA304)→...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com