Improved novel middle roller vellicating device of six-roller mill

A technology of six-high rolling mill and intermediate roll, which is applied in the driving device of metal rolling mill, metal rolling, metal rolling, etc., can solve the problems of complex structure and poor twitch synchronization, and achieve good synchronization, reliable action, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

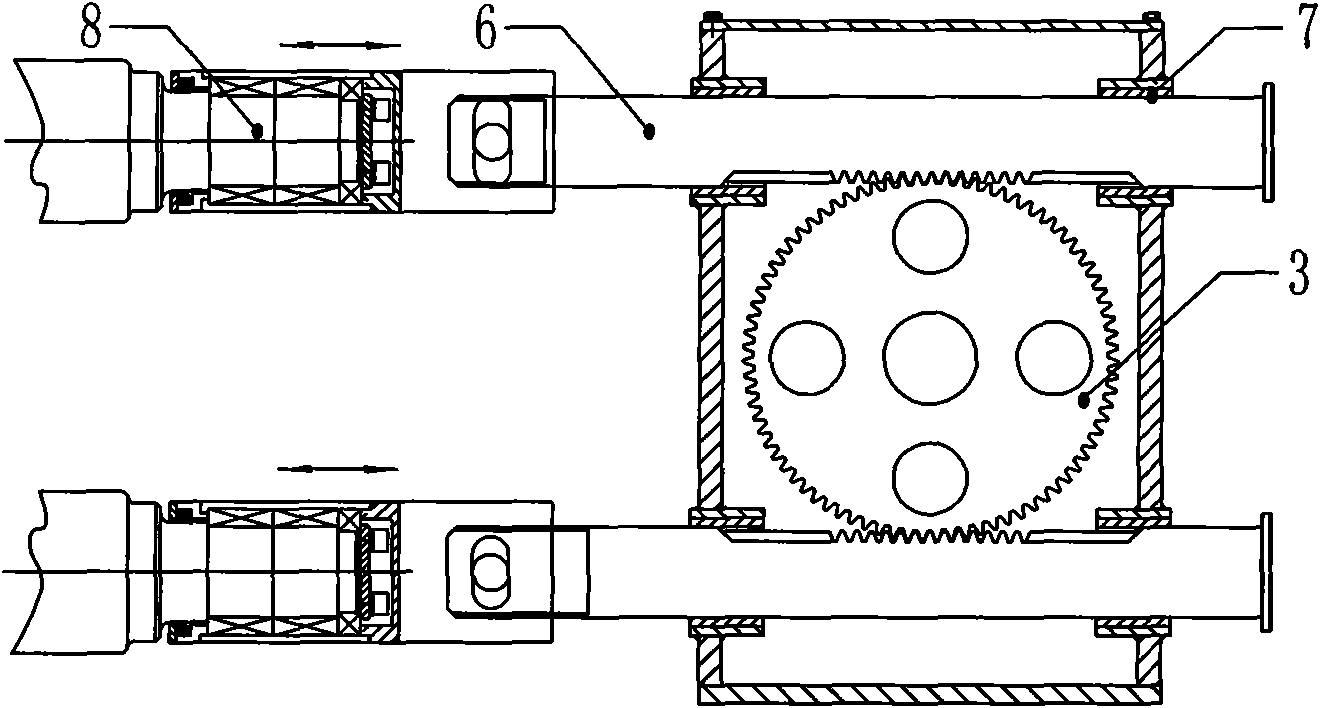

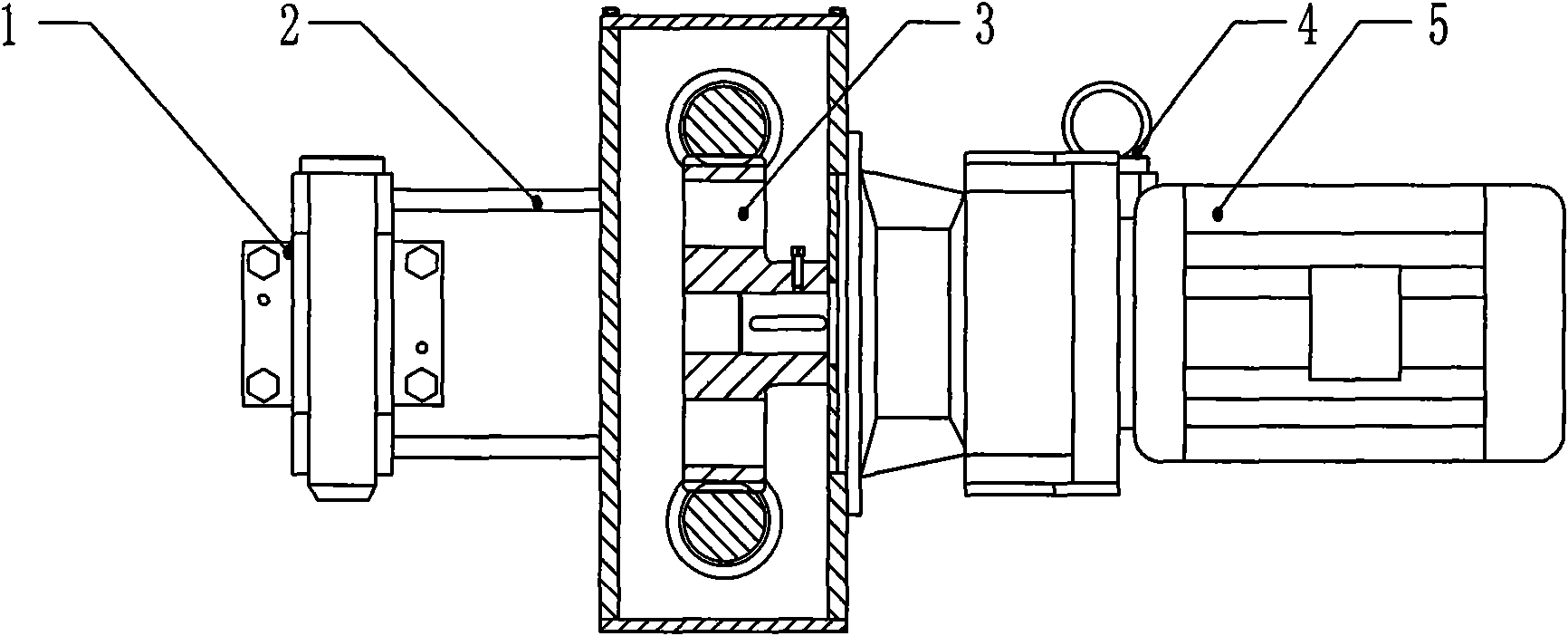

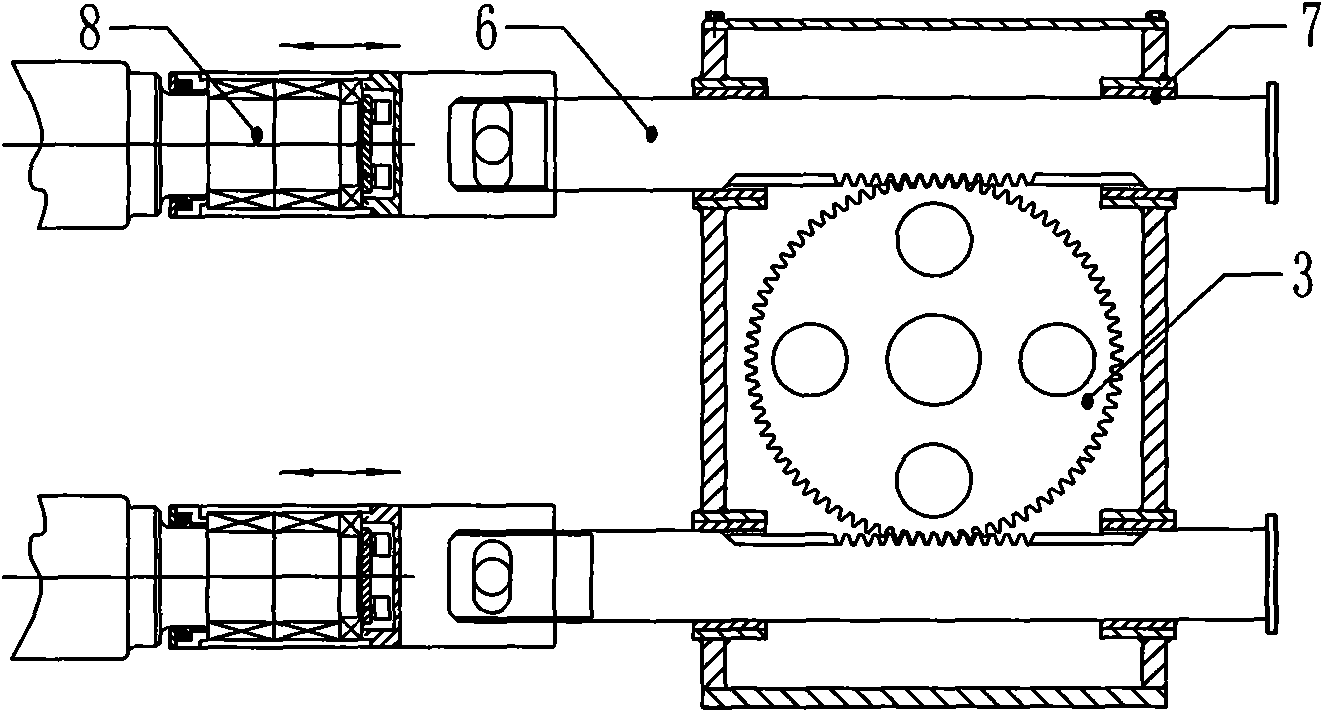

[0009] See figure 2 , the present invention comprises gear 3, rack 6 and reduction box 5, and rack 6 connects intermediate roll 8 respectively, and gear 3 is meshed with rack 6, and gear 3 and gear shaft are connected to output end of reduction box 5. The gear 3 is installed on the bracket 2; the bracket 2 is installed on the support 1; the rack 6 is installed on the bracket 1 through the copper sleeve 7; the rack 6 is connected with the middle roller by bolts. The screw hole connecting the rack 6 and the intermediate roller is a long waist hole. figure 1 Among them, 4 is the pin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com