Digitalized manufacture workshop material real-time distributing system based on Ultra Wideband (UWB)

A technology for manufacturing workshops and materials, applied in the field of real-time distribution of materials in digital manufacturing workshops, can solve the lack of effective methods and means for real-time positioning and tracking of digital manufacturing workshops, lack of workshop material distribution tasks and distribution path planning and guidance, and material distribution Real-time positioning and tracking of the car cannot be realized, etc., to achieve high indoor application environment reliability, accurate real-time positioning and tracking, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

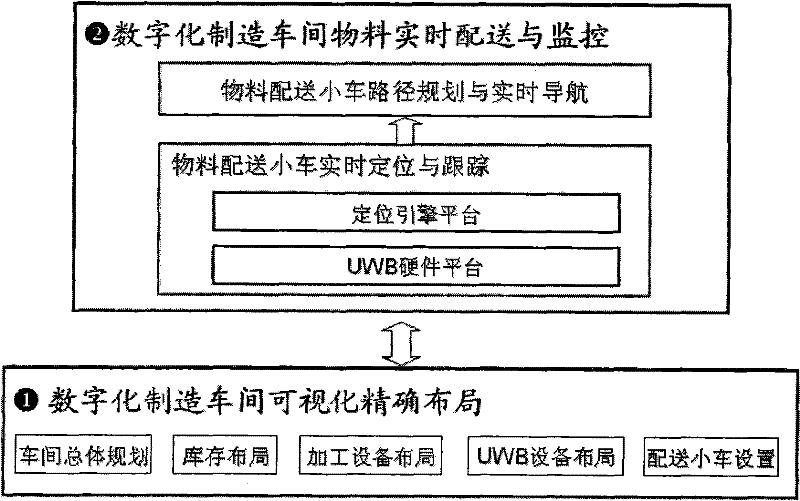

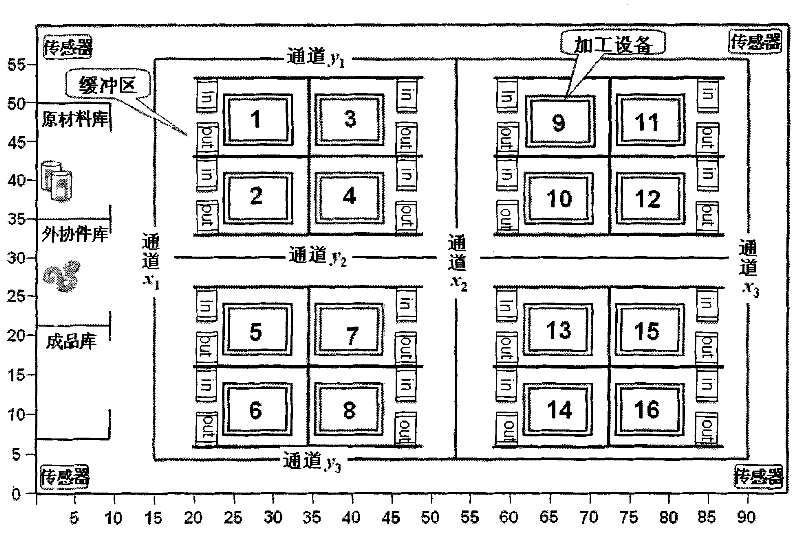

[0029] see figure 1 : The present invention mainly comprises two big modules: the visualized precise layout module of the digital manufacturing workshop and the real-time delivery and monitoring module of the material in the digital manufacturing workshop. First, with the support of the visualized and precise layout module of the digital manufacturing workshop, the visualized and precise layout of the relevant manufacturing resources in the workshop is carried out. Then establish a digital manufacturing workshop material distribution path planning model, use the branch and bound algorithm to plan the material distribution path in the workshop, and display the path in real time on the digital manufacturing workshop visual layout platform to provide real-time path navigation for material distribution personnel. Finally, with the support o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com