Liquid level measuring method and device based on isosceles right triangular prism

A liquid level measuring device and isosceles right angle technology, which is applied in the direction of measuring device, liquid/fluid solid measurement, lubrication indicating device, etc., can solve problems such as difficult system errors, and achieve the effect of small precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

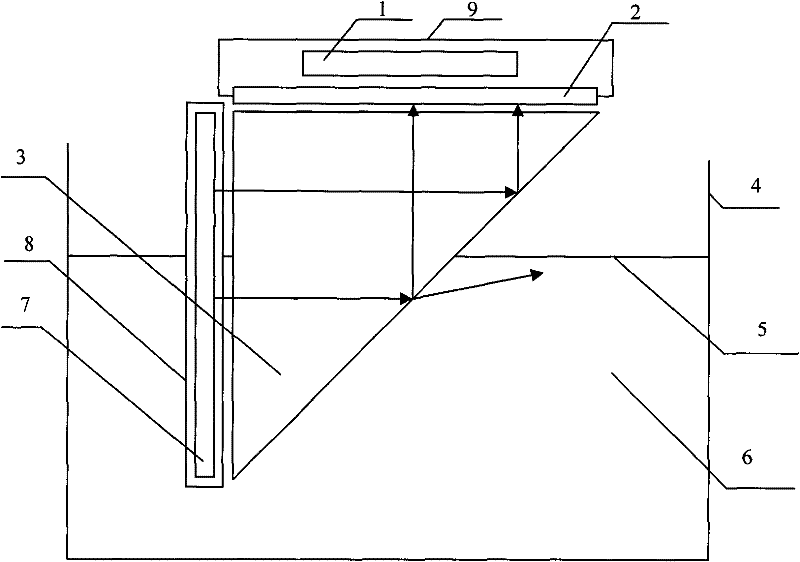

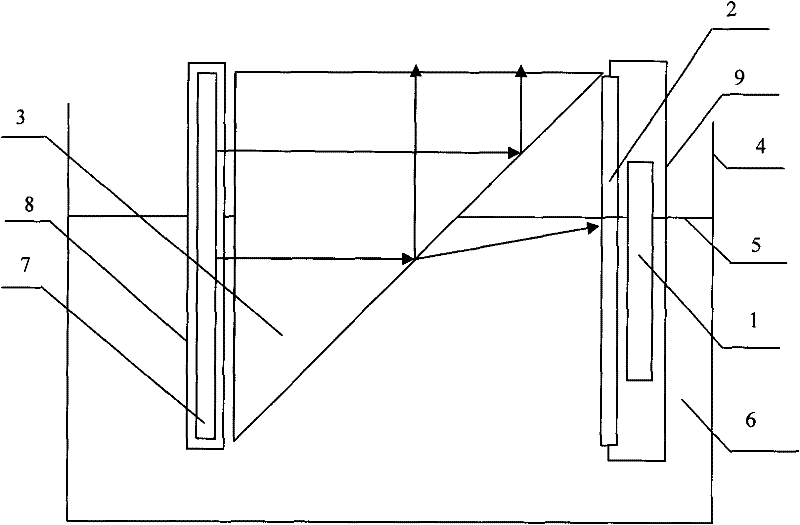

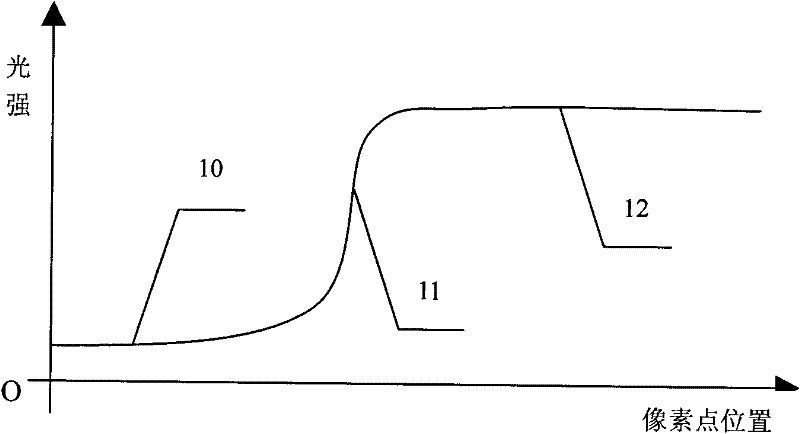

[0016] combine figure 1 , the liquid level measuring device based on the isosceles right-angled prism includes a line light source 7 and a transparent protective cover 8, an isosceles right-angled prism 3, an airtight box 9, a linear array CCD2, a circuit unit 1 (including: a linear array CCD2 drive circuit, a data acquisition and processing circuit and data transmission circuit), the linear array CCD2 is embedded in a slot with a width and length slightly larger than the width and length of the CCD2 chip of the airtight box 9, and the inner and outer sides of the airtight box 9 are opposite to the slots of the CCD2 The slit is sealed, while ensuring that the protective glass of CCD2 protrudes slightly from this side of the airtight box 9, and the line light source 7 and the linear array CCD2 are respectively placed on the side where the two right-angled sides of the cross-section of the prism 3 are located and are located on the same side. In the vertical plane, it is require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com