High-efficiency energy-saving horizontal self-sucking pump

A high-efficiency, energy-saving, self-priming pump technology, used in non-variable-capacity pumps, pumps, drive pumps, etc., can solve problems such as reducing pump efficiency, and achieve the effect of reducing volume loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention, all equivalent technical solutions also belong to the category of the present invention, and the patent protection scope of the present invention should be defined by each claim.

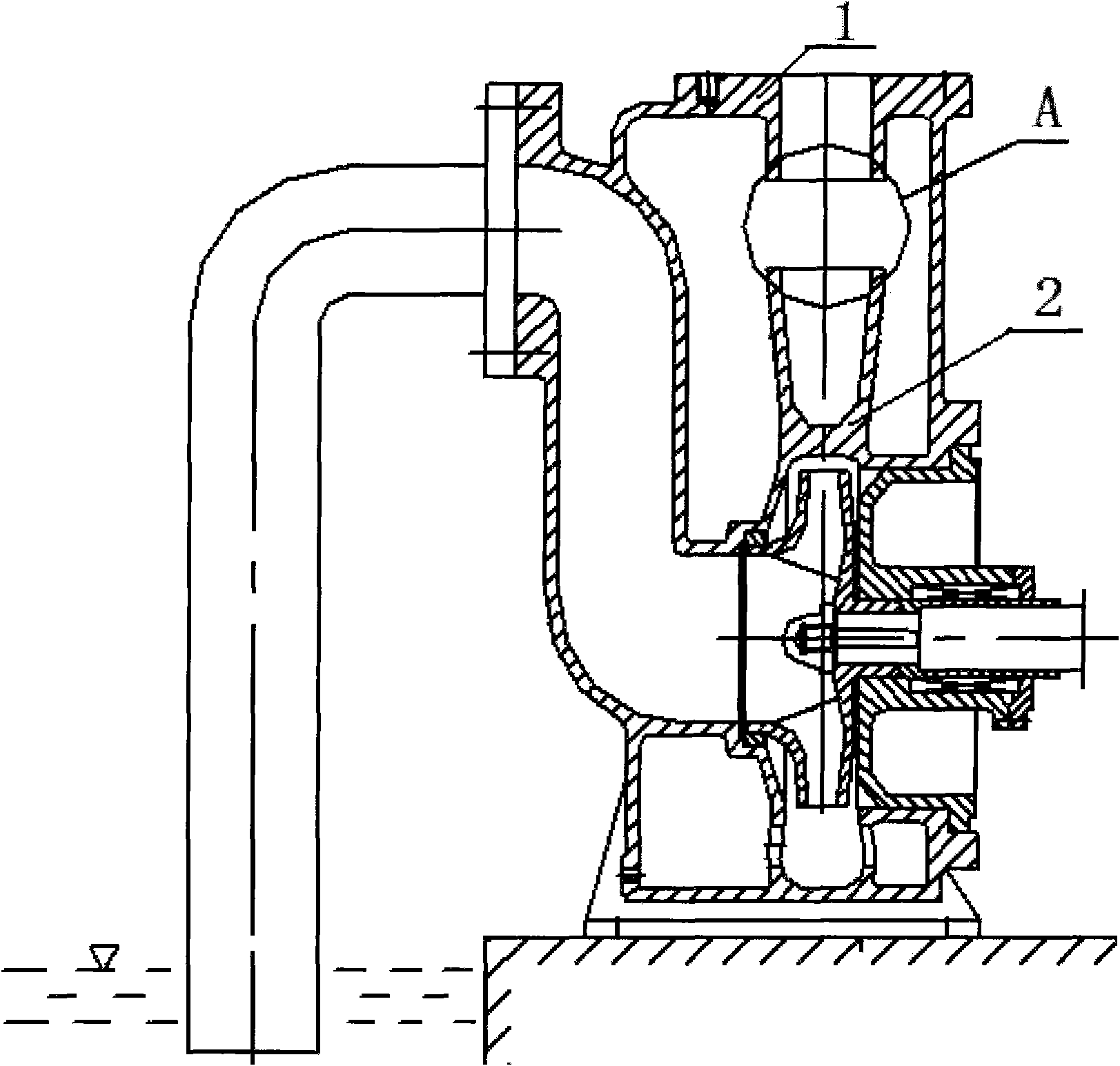

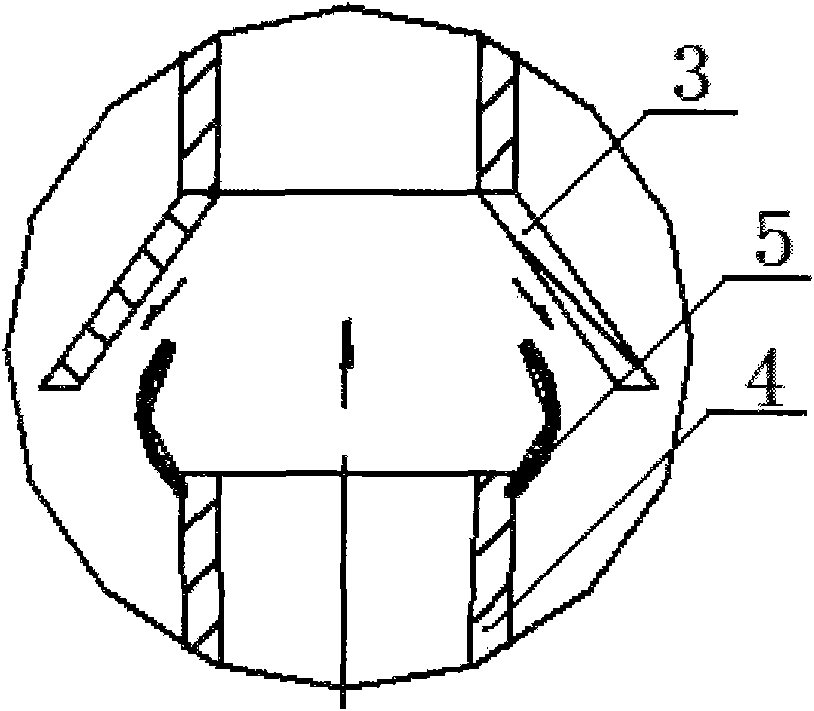

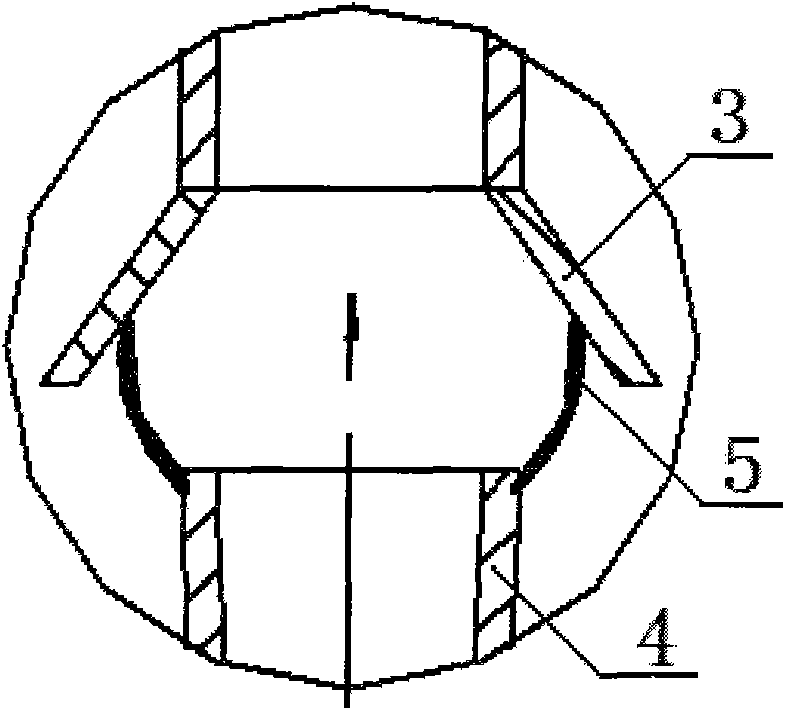

[0013] From Figure 1 to Figure 3 It can be seen from the figure that a high-efficiency energy-saving horizontal self-priming pump includes a pump body 1 and a pump casing 2. The pump body 1 and the pump casing 2 are integrated, and it is characterized in that: at the outlet of the pump body 1 A flexible material sleeve 5 is arranged on the pipe 3 and the outlet end 4 of the pump casing 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com