Hydraulic auxiliary support structure for recoiling machine

An auxiliary support and coiler technology, which is applied in the field of hydraulic auxiliary support structures, can solve the problems of uneven edges of coiled strips, equipment accidents, endangering the life and safety of operators, etc., to ensure product quality and output, coiling The effect of stable tension and improving enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

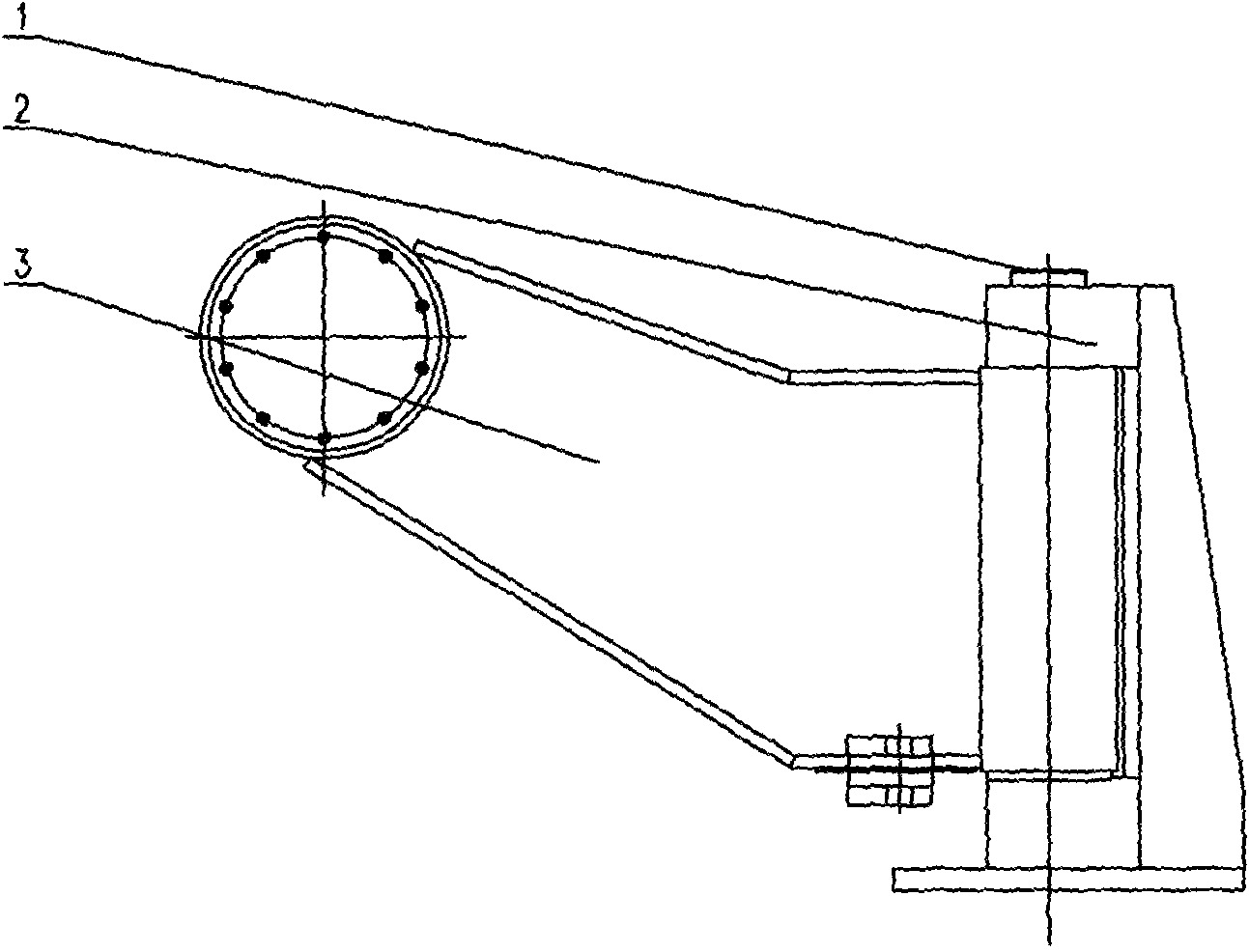

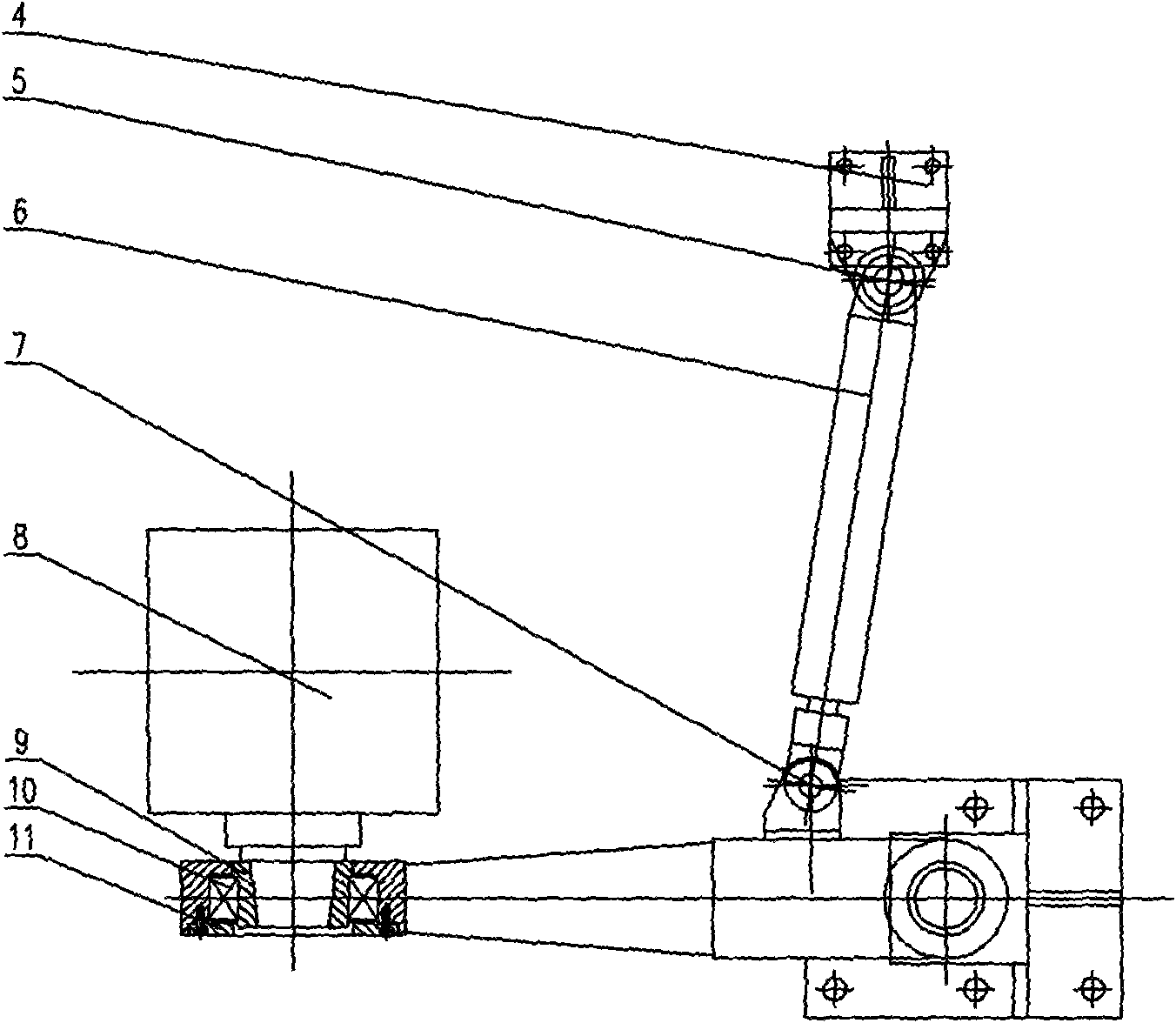

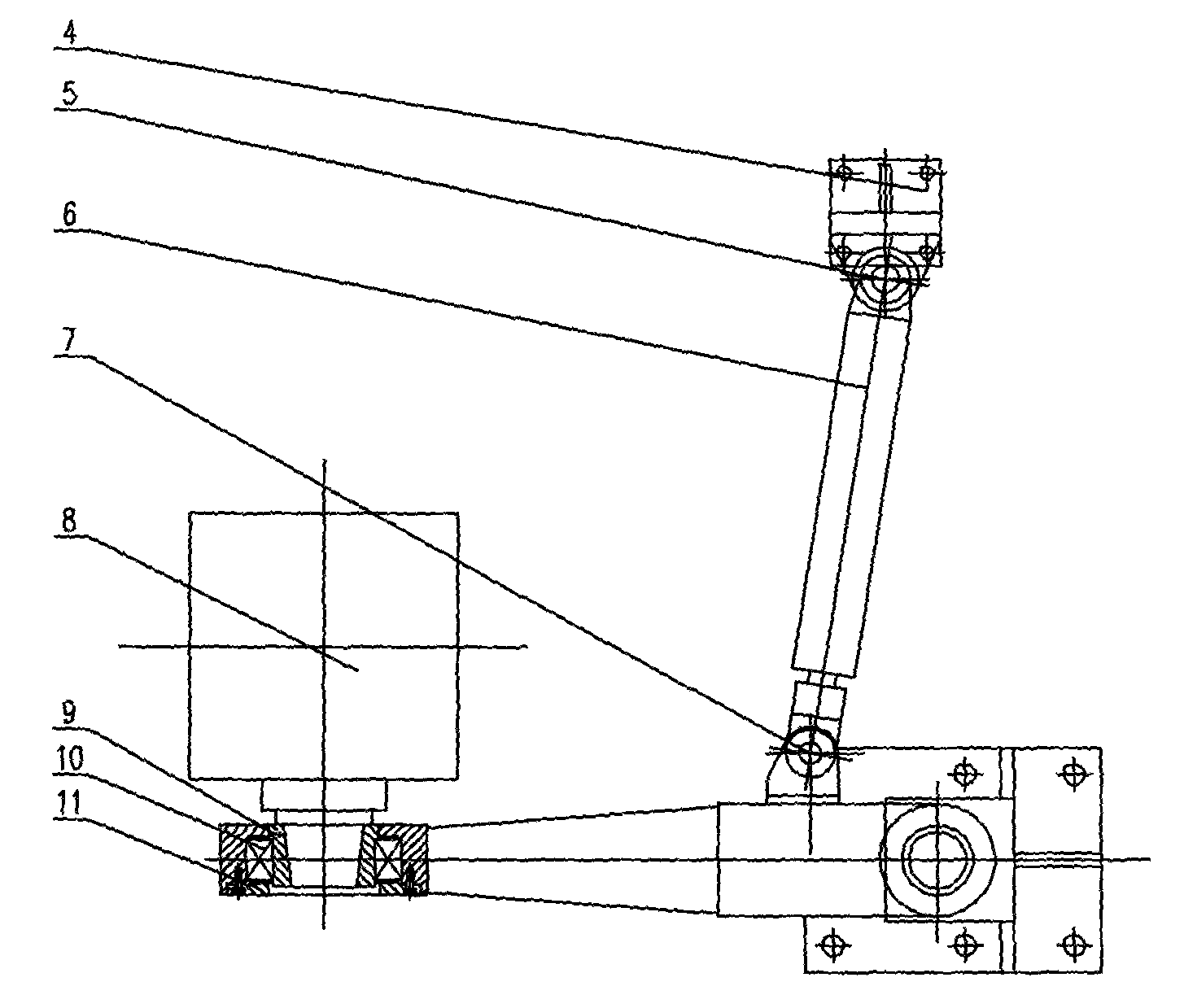

[0010] Such as Figure 1 ~ Figure 2 As shown, it includes a rotating shaft 1, a column 2, a support arm 3, an oil cylinder seat 4, a first pin shaft 5, an oil cylinder 6, a second pin shaft 7, a taper sleeve 9, a bearing 10, a bearing cover 11, and the like.

[0011] The present invention adopts the bearing 10 to be installed in the inner hole of the support arm 3, and then the taper sleeve 9 is installed in the inner hole of the bearing 10, and then the bearing cover 11 is used to compress the bearing 10, and tightened with bolts; the support arm 3 passes through the rotating shaft 1 and the column 2 are assembled and connected together, and then at the bottom of the support arm 3, the second pin shaft 7 is connected with the oil cylinder 6, and the oil cylinder 6 is connected with the oil cylinder base 4 with the first pin shaft 5.

[0012] After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com