Compact hydraulic accumulator

一种蓄能器、缸体的技术,应用在执行器蓄能器、流体压力致动装置、运输和包装等方向,能够解决没有提供保护套筒完整性、高昂、不能进行维修等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description is merely exemplary in nature, and is not intended to limit the disclosure, application or uses. It should also be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features. With respect to the disclosed methods, the order of the steps presented is exemplary in nature, and thus not required or critical.

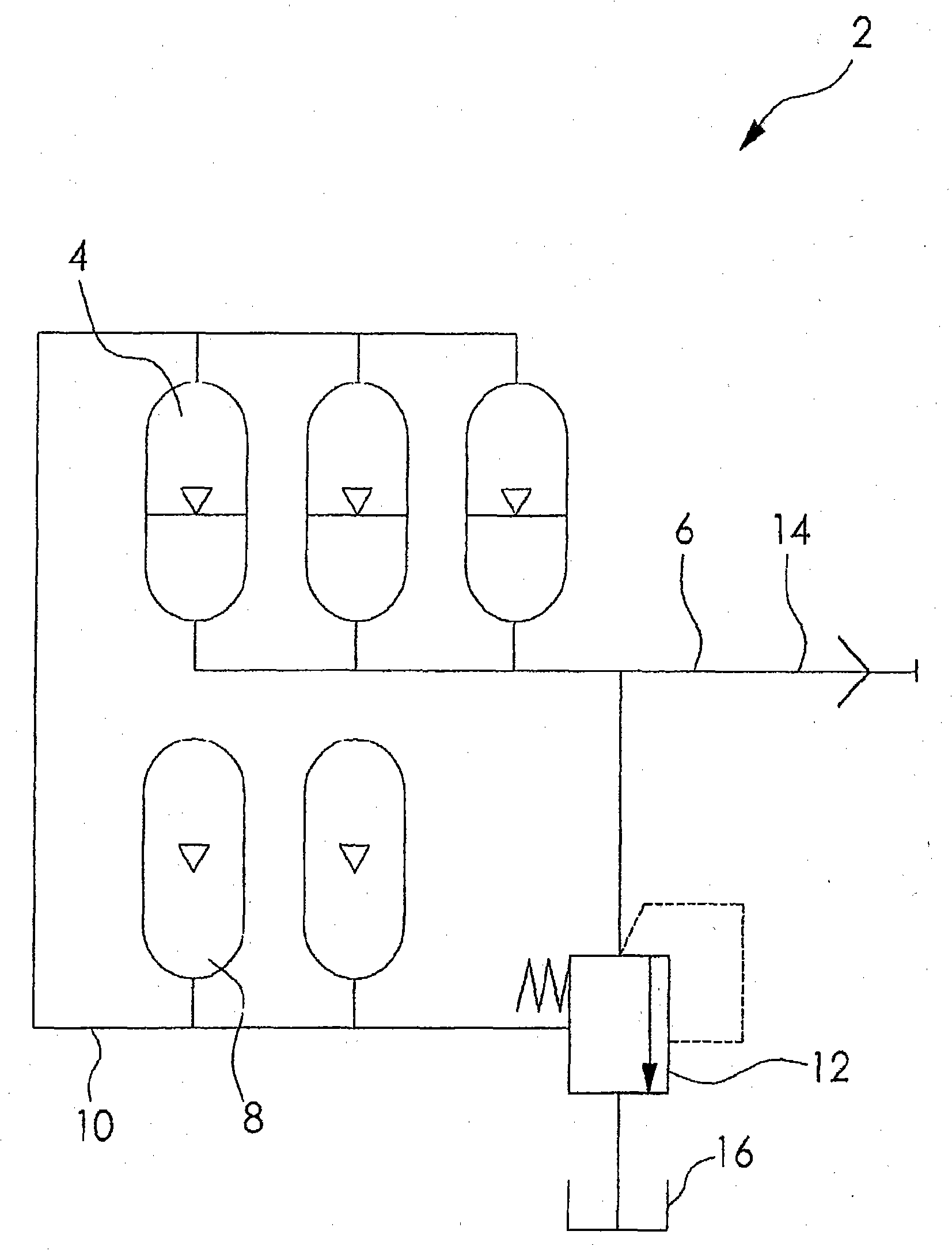

[0036] figure 1 An overall schematic diagram of the accumulator system 2 is shown in . The accumulator system 2 comprises at least one accumulator cylinder 4, whose fluid side connection is connected to a common fluid network (fluidnetwork) 6; zero or more auxiliary gas cylinders 8, whose gas side connection is connected to the accumulator The cylinders 4 share a common gas grid 10 ; and a gas-mediated differential pressure relief valve 12 . The accumulator system 2 is coupled on the main hydraulic circuit by a connector 14 and the pressure relief valve 12 has a connection to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com