Construction method for pouring after settlement of reinforced concrete continuous beam with cohesive pre-stress

A technology of reinforced concrete and bonded prestressing, which is applied to the processing of formwork, processing of building materials, and preparation of building components on site. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

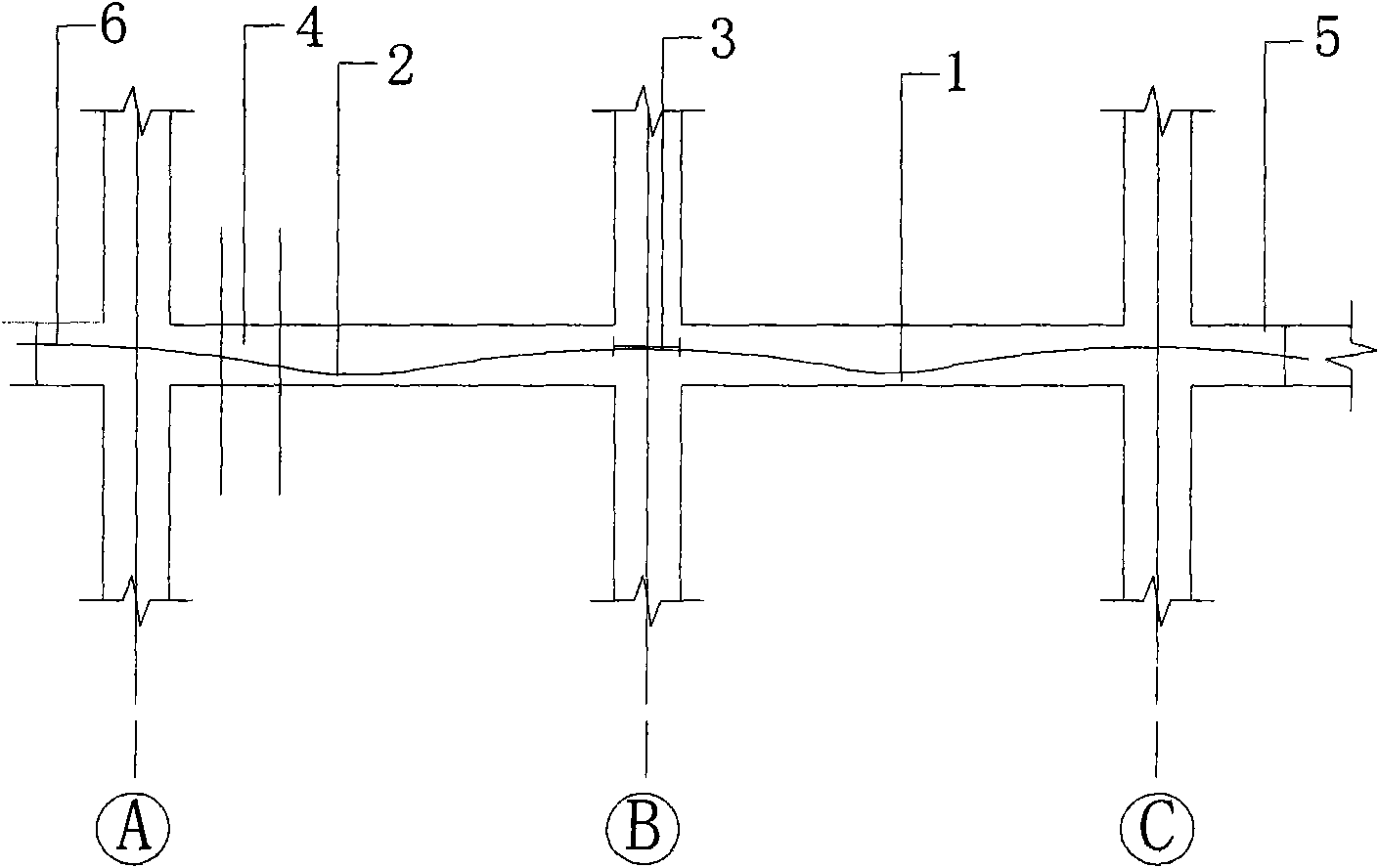

[0020] Figure 1 to Figure 5 It is a specific embodiment of the present invention.

[0021] exist figure 1 In the process, after the concrete strength reaches the tensile strength, stretch the prestressed steel bar 1, remove the support system at this place, and reserve the early demolition support system at the tensioned steel bar 2; For the concrete poured with the belt, after the strength of the concrete poured with the belt reaches the tensile strength after settlement, the second prestressed steel bar 2 is stretched, and the supporting system at this place is removed.

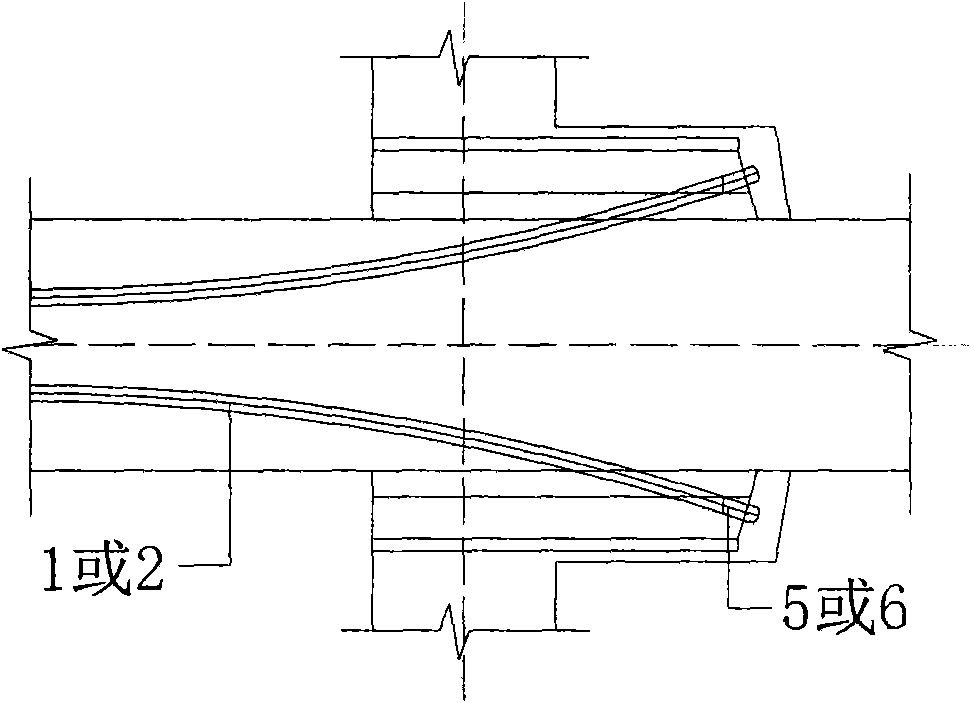

[0022] exist figure 2 In , tension bar 1 and tension bar 2 are overlapped through beam haunches at beam haunch tension end 5 and beam haunch tension end 6.

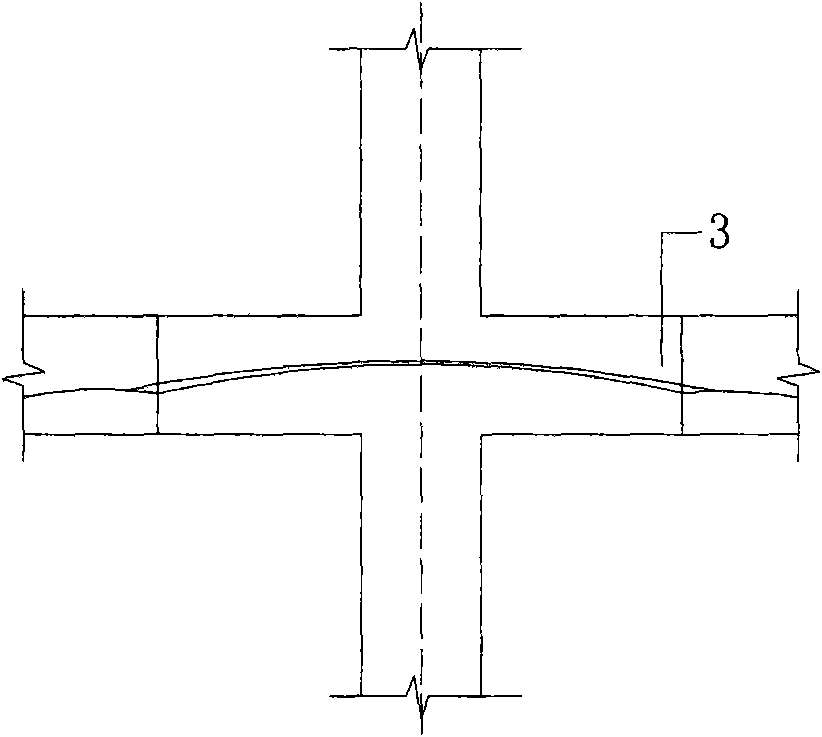

[0023] exist Figure 4 In the above, the tensioned first prestressed steel bar 1 and the tensioned second stressed steel bar 2 are lapped at the prestressed steel bar overlap 3 through the beam haunch. The application of the construction method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com