A wind turbine, a method for compensating for disparities in a wind turbine rotor blade pitch system and use of a method

A wind turbine and pitch technology, applied in the control of wind turbines, wind turbines, machines/engines, etc., can solve problems such as wind turbine fatigue, rotor blade deterioration control, etc., and achieve the effect of optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

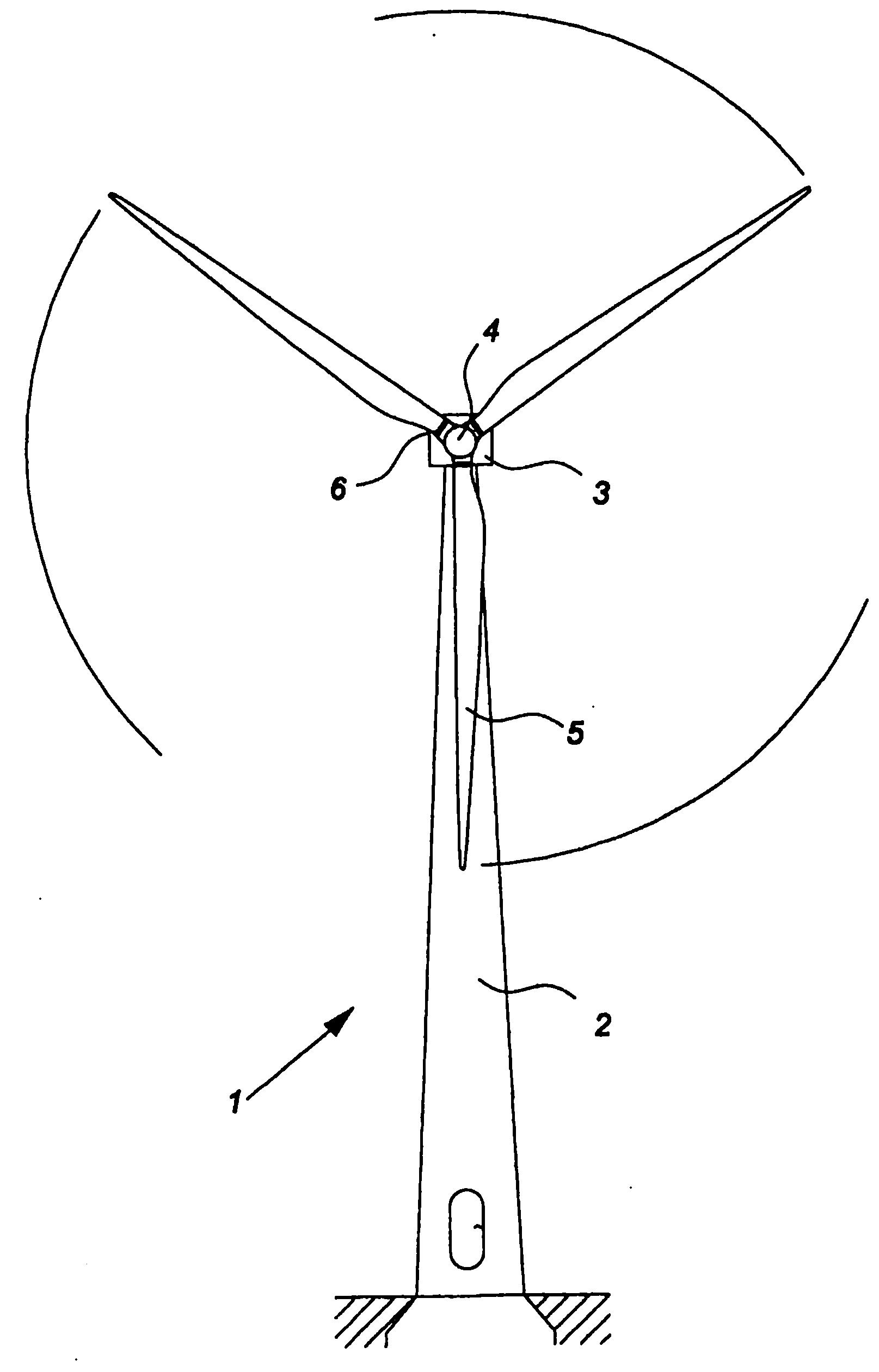

[0056] figure 1 A modern wind turbine 1 is shown with a tower 2 and a wind turbine nacelle 3 arranged on top of the tower.

[0057] A wind turbine rotor comprising at least one blade (eg three wind turbine blades 5 shown) is connected to the hub 4 via a pitch mechanism 6 . Each pitch mechanism includes a blade bearing and a pitch adjustment device to pitch the blade. The pitching process is controlled by the pitch controller.

[0058] As shown in the figure, wind force above a certain level pushes the rotor and enables it to spin in a direction perpendicular to the wind force. This rotational motion is converted into electrical power, typically supplied to the utility grid, as is well known to those skilled in the art.

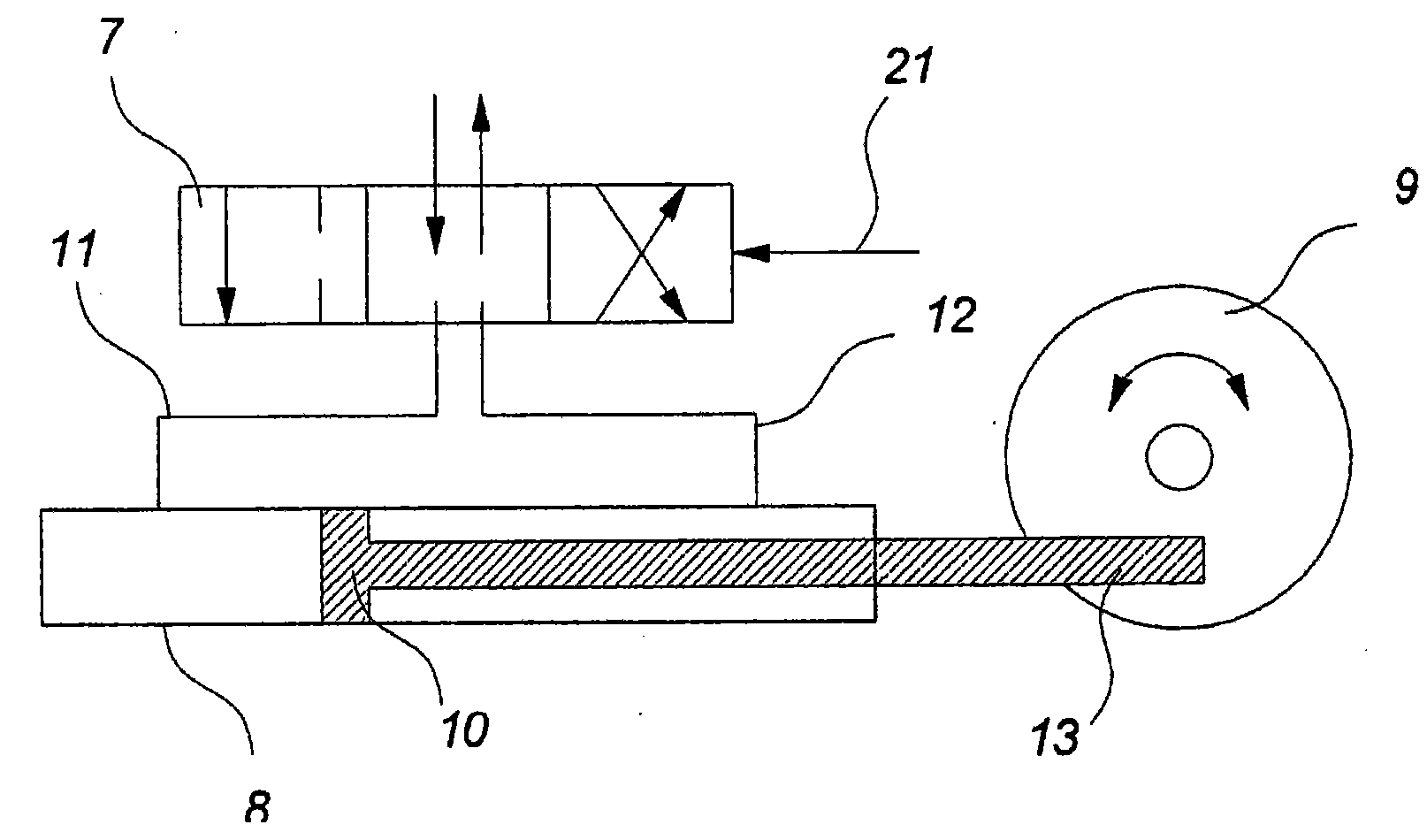

[0059] One main task of the pitch mechanism 6 of a wind turbine is to turn the rotor blades 5 around their length and for various embodiments of the wind turbine the pitch system is a hydraulic system.

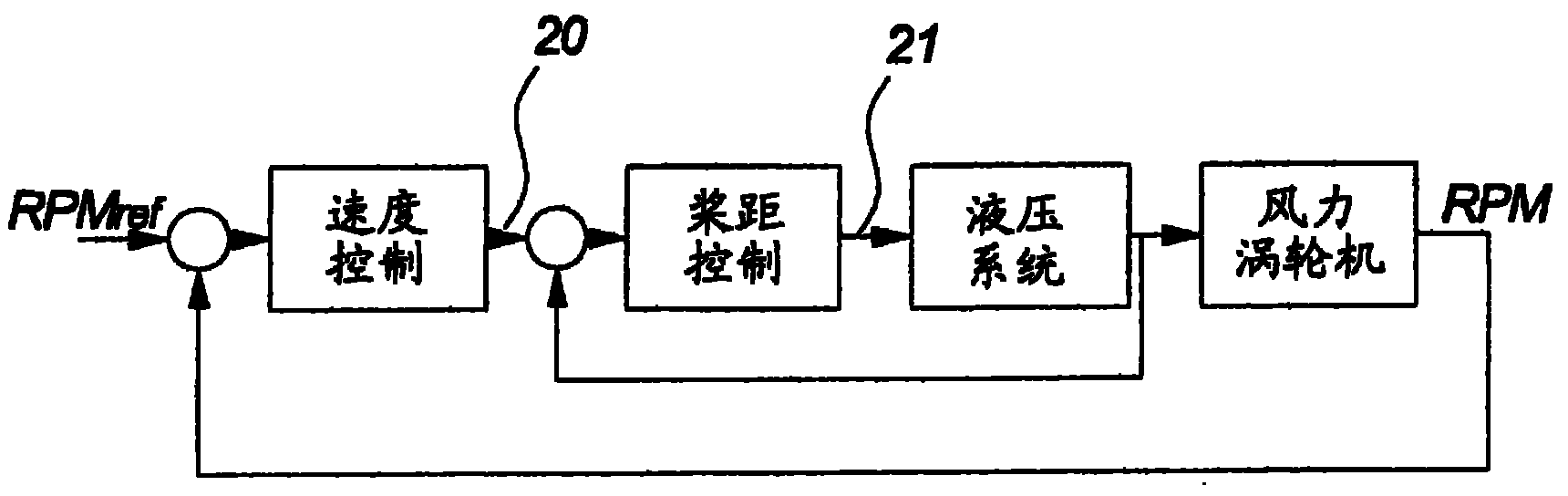

[0060] For other embodiments of the wind turbine, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com