Insulator detecting robot

A technology of insulator detection and robot, which is applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of large distance and potential difference between the insulator string and the iron tower, the insulator live detection robot, and the wear and tear of the anti-pollution flashover coating on the insulator porcelain skirt. , to achieve the effect of fast detection operation, reliable lap joint and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

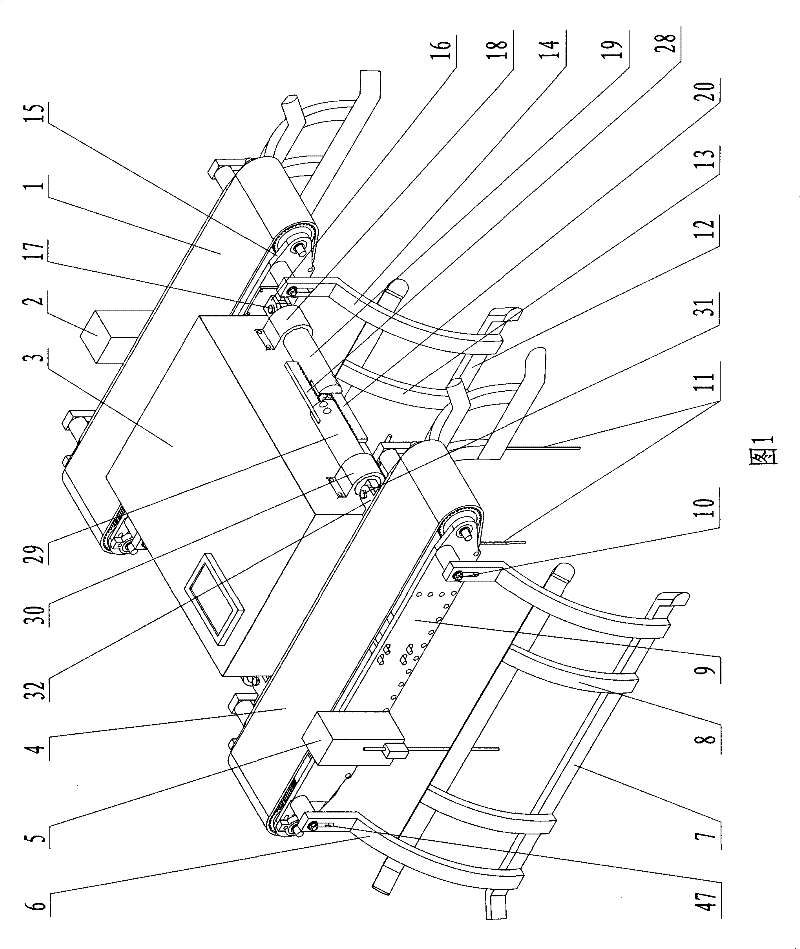

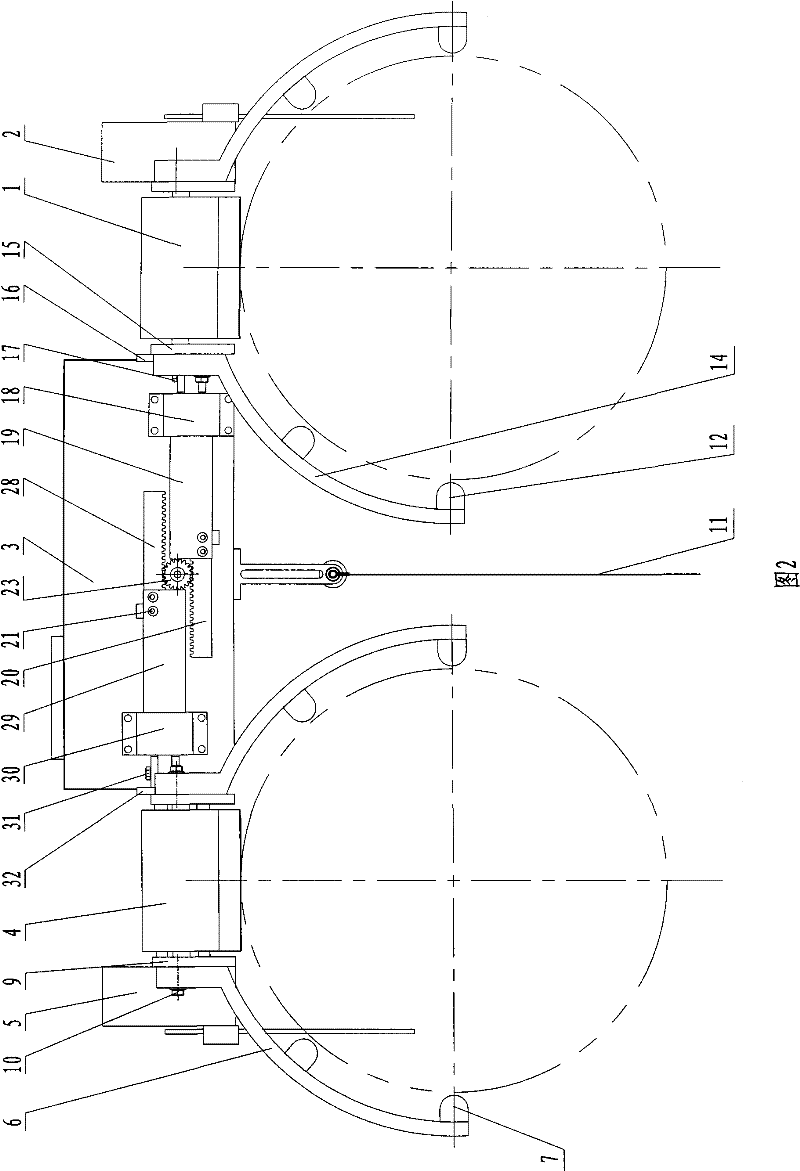

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The present invention walks on the horizontal double-string insulators of the tension tower, such as figure 1 , figure 2 As shown, it includes the first crawler wheel 1, the box body 3, the second track wheel 4, the pitch-variable telescopic mechanism and the probe drive mechanism, the pitch-variable telescopic mechanism is installed on the casing 3, and the first and second track wheels 1 and 4 are located at Both sides of the box body 3 are respectively hinged with the pitch-variable telescopic mechanism, and the first and second track wheels 1, 4 are respectively connected with the first and second stroke sensors 2, 5; the bottom of the box body 3 is provided with a probe driving mechanism. The first and second crawler wheels 1 and 4 are respectively equipped with height-adjustable safety protection mechanisms.

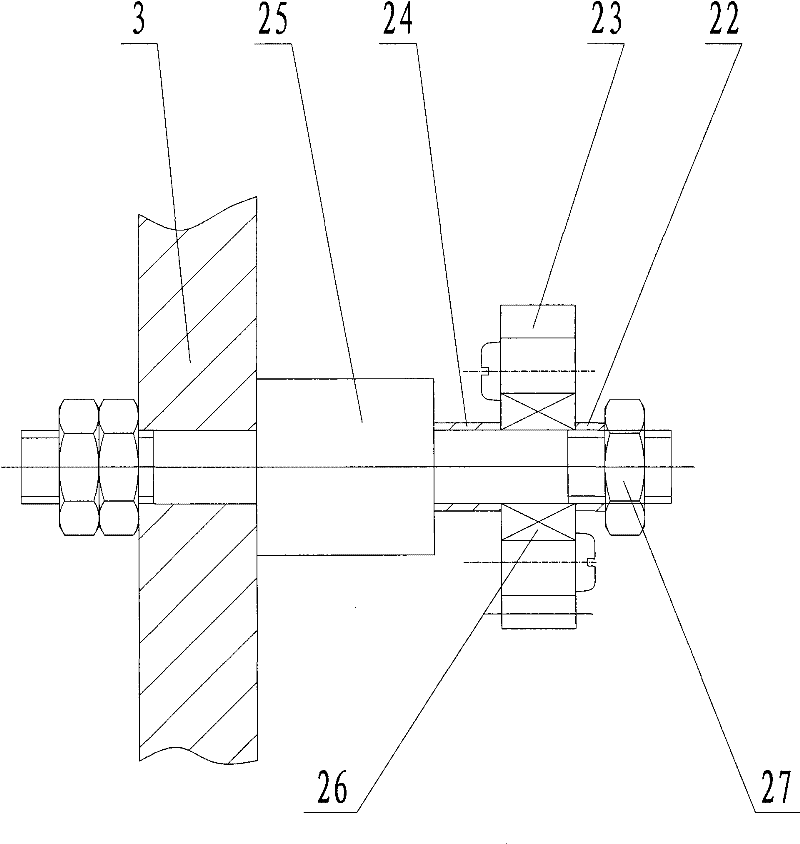

[0026] like Figure 1~3 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com