One-dimensional positioning method of motion platform based on linear magnetic steel array

A motion platform and magnetic steel array technology, which is applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve the problems of complex circuits and optical equipment, high cost, and loss of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

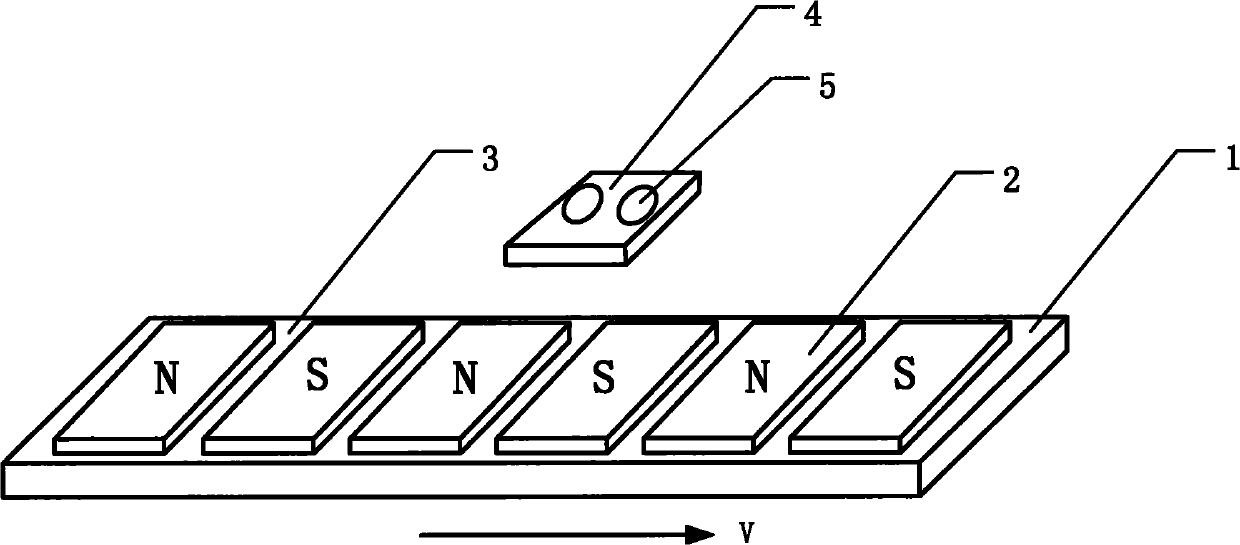

[0046] The minimum number of the linear Hall sensors 5 placed on the motion platform 4 is determined by the number of unknown parameters contained in the linear magnetic steel array 2 magnetic flux density distribution model, and on this basis, the more the number of placed The more, the more beneficial it is to reduce the uncertainty of the motion platform 4 phase solution results, therefore, n is at least equal to 2.

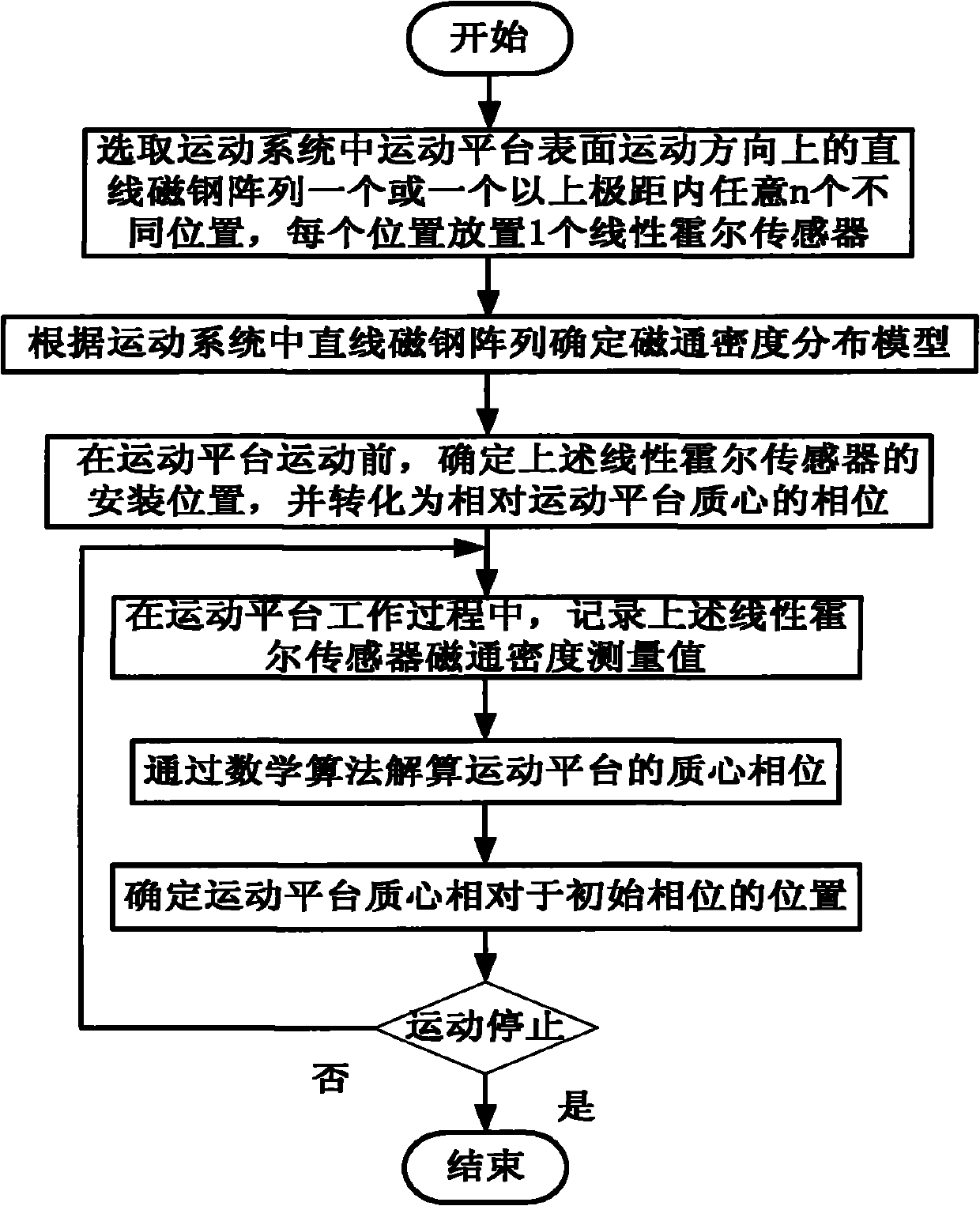

[0047] refer to image 3 In the following, two linear Hall sensors 5 (ie n=2) are placed on the moving direction of the surface of the moving platform 4, and the unscented Kalman filter algorithm is used as an example to describe the present invention, so as to further understand the present invention.

[0048] 1) Select any two different positions within one pole pitch of the linear magnetic steel array 2 on the surface movement direction of the motion platform 4 in the motion system, and place a linear Hall sensor 5 at each position;

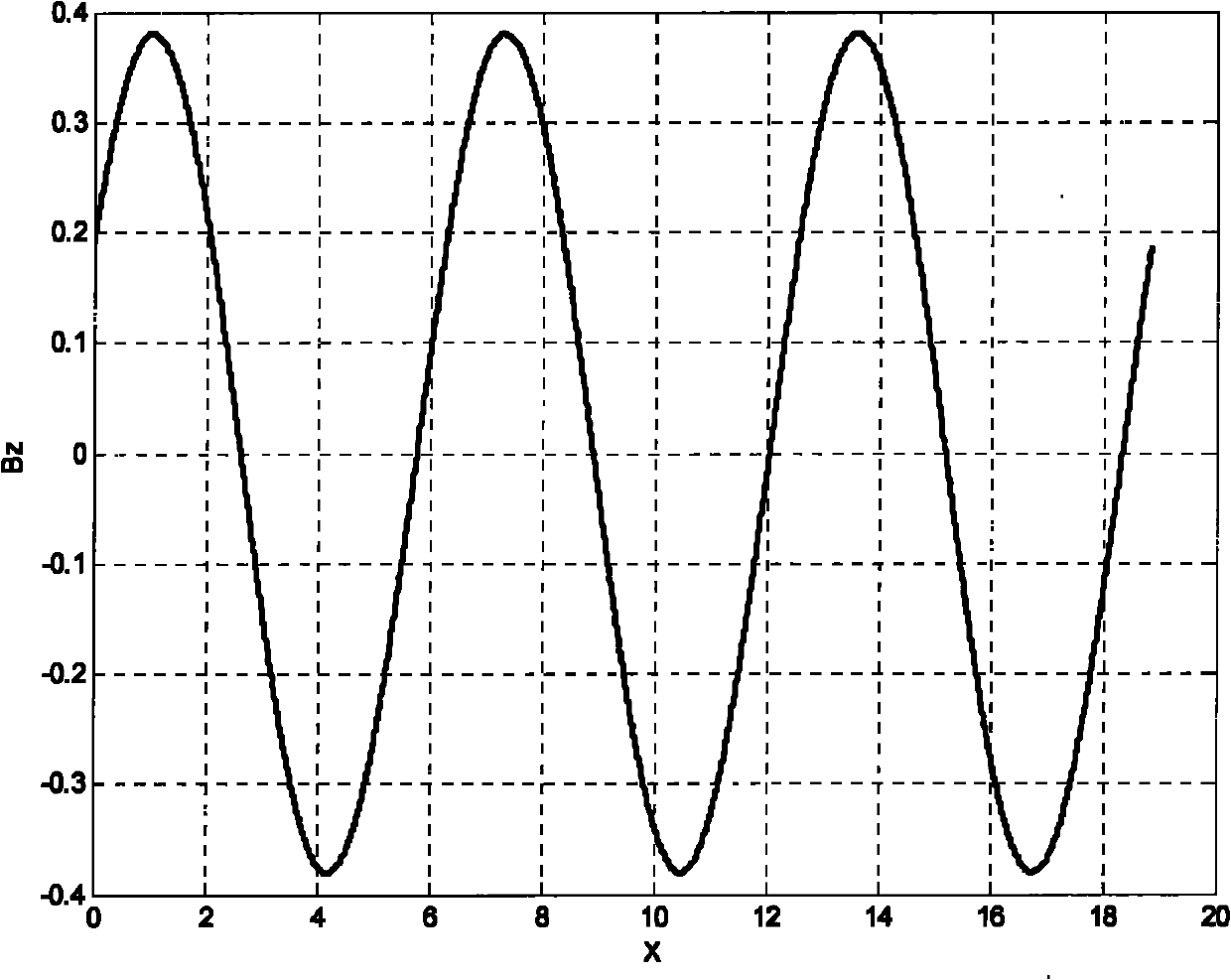

[0049] 2) Determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com