Oiling machine for lubricating fuel tank at wheel rim of motor train unit

A wheel rim lubricator, EMU technology, applied in the direction of engine lubrication, track lubrication, engine components, etc., can solve the problems of high labor intensity, low oil injection efficiency, overflow of oil injection, etc., to improve oil injection efficiency and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

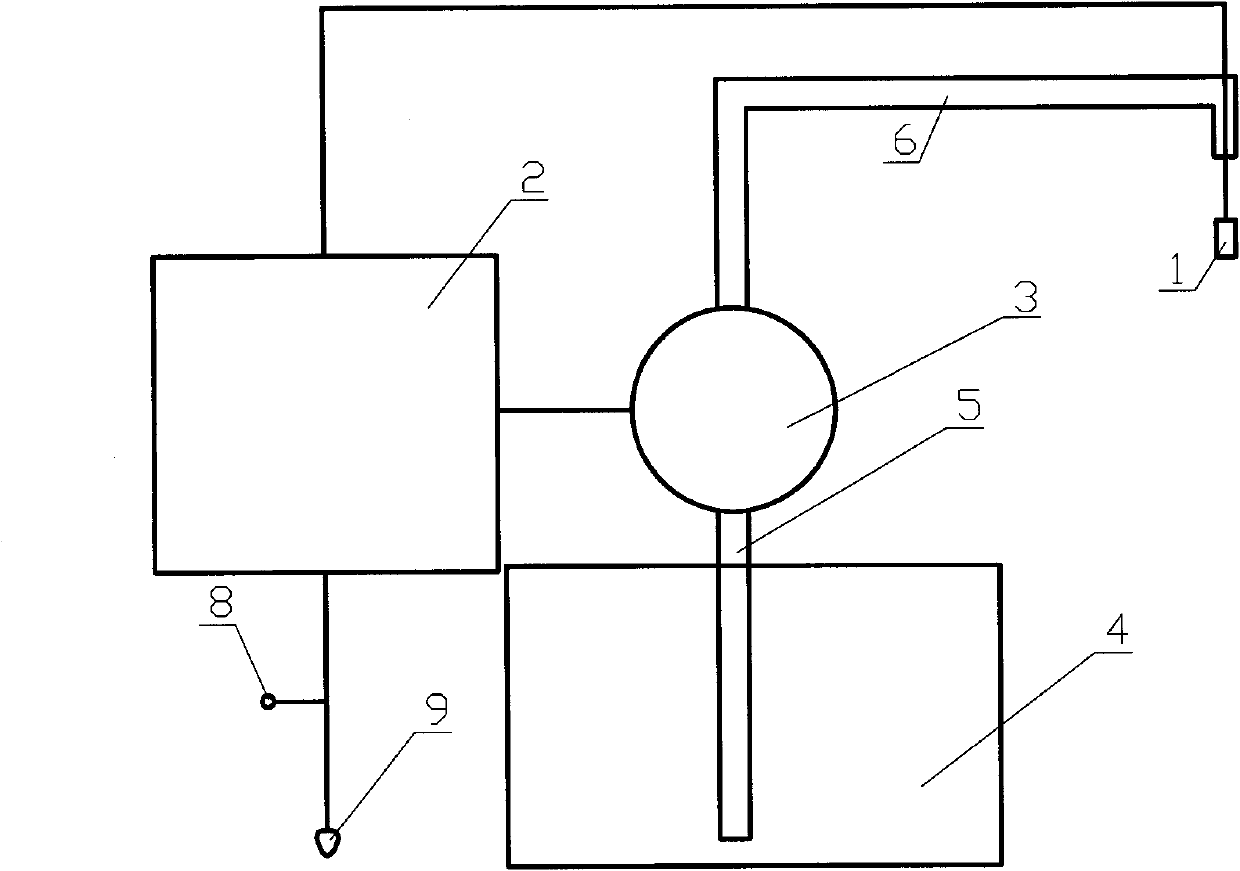

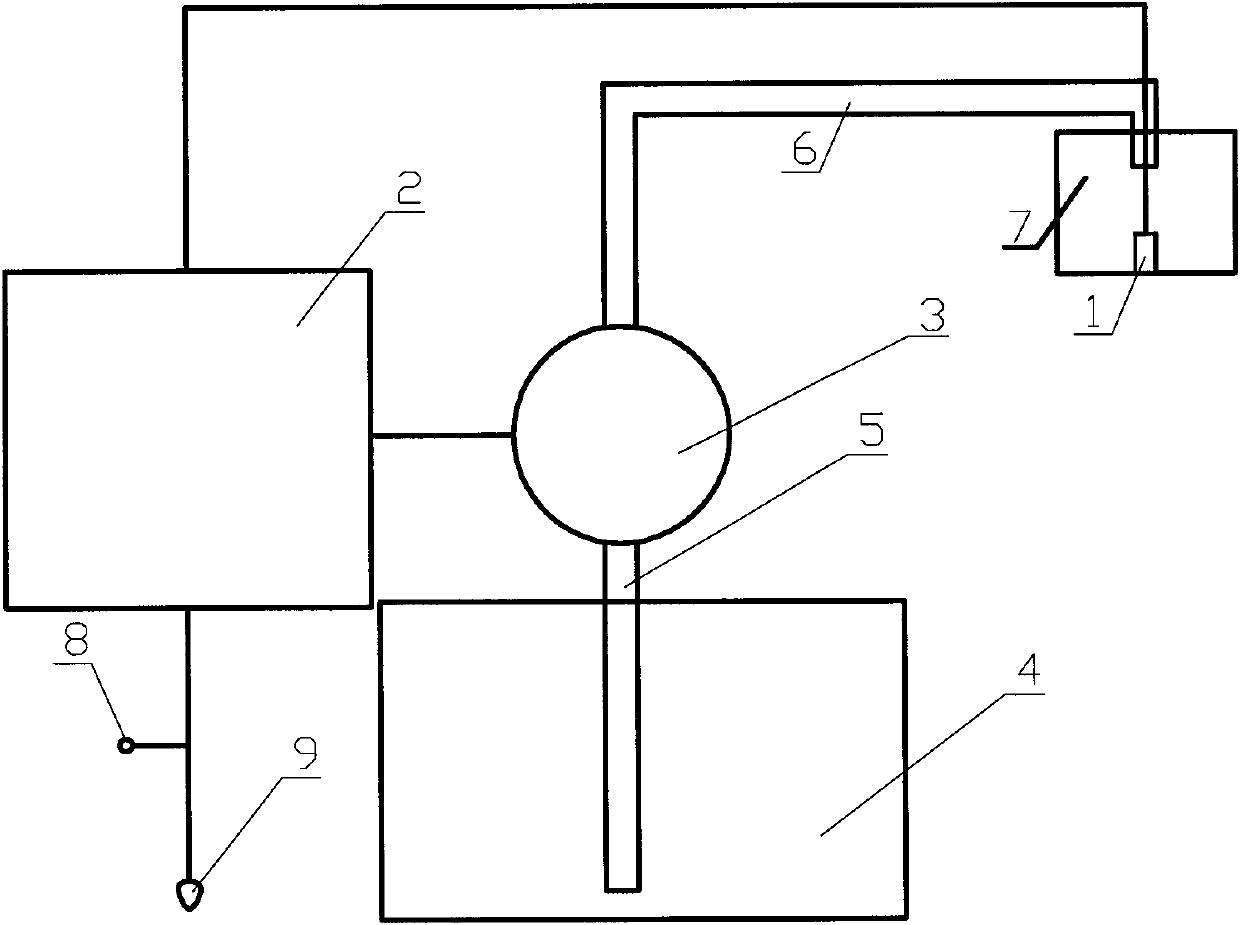

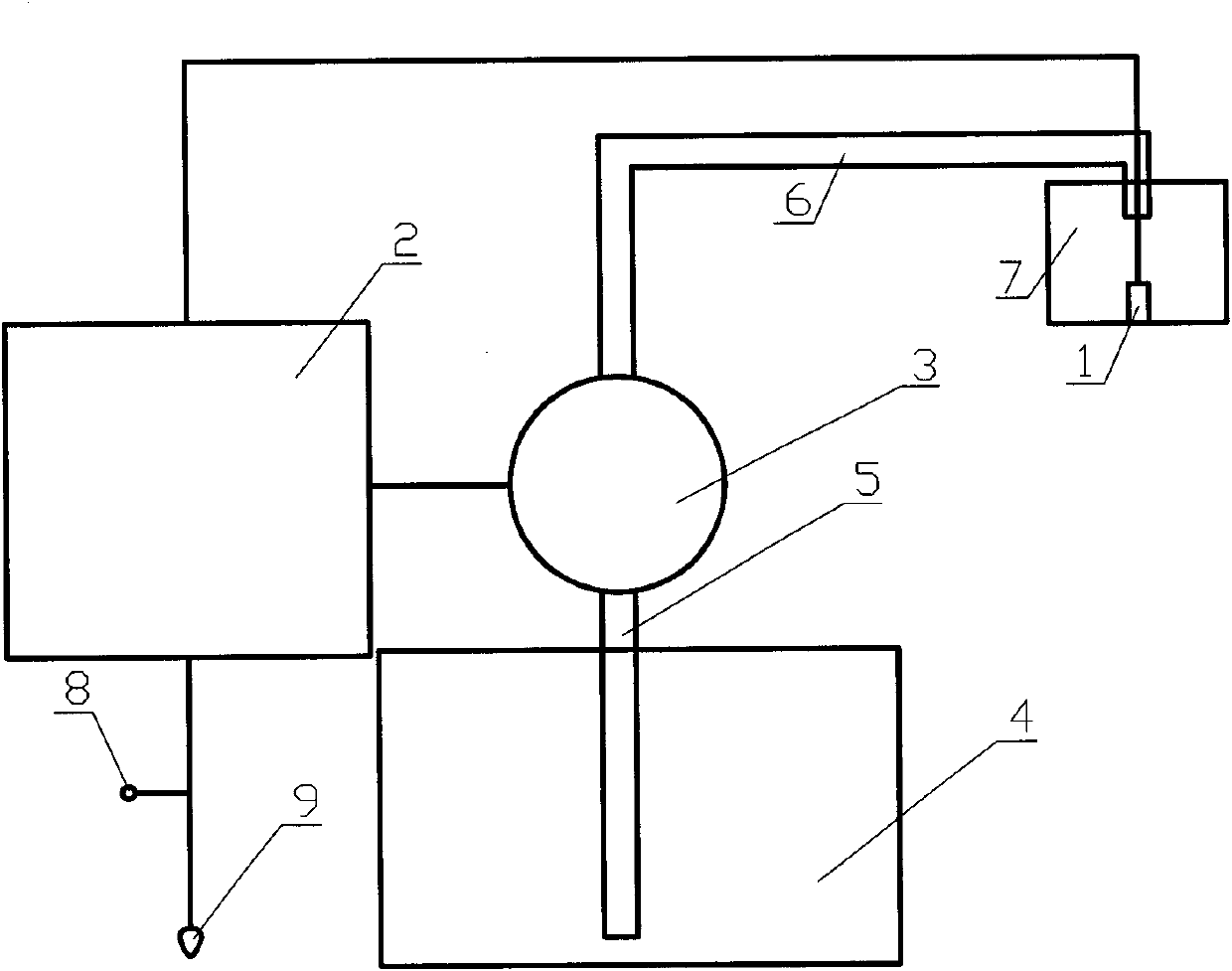

[0010] exist figure 2 , first insert the plug (9) into the power supply, then put the sensor (1) and the upper oil pipe (6) in the EMU wheel flange lubricator oil tank (7), turn on the switch (8), the sensor (1) will Automatically detect the amount of remaining oil in the wheel flange lubricator oil tank (7) of the EMU, and send the signal to the controller (2). When the oil amount is lower than a certain value, the controller (2) supplies power to the oil pump (3), and the oil pump ( 3) Start working, pump the oil in the oil storage tank (4) into the oil tank (7) of the rim lubricator of the EMU until the oil volume reaches a certain value, the controller (2) stops supplying power to the oil pump (3), The oil pump (3) stops; when the oil quantity detected by the sensor (1) is equal to or higher than a certain value, the controller (2) does not supply power to the oil pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com