Excavation supporting method for tunnel construction

A tunnel construction and tunneling technology, which is applied in the field of ancient rock pile geological V, basalt geological tunnel excavation and support, and VI level surrounding rock tunnel field, to achieve the effect of shortening construction time, fast forming and reducing construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

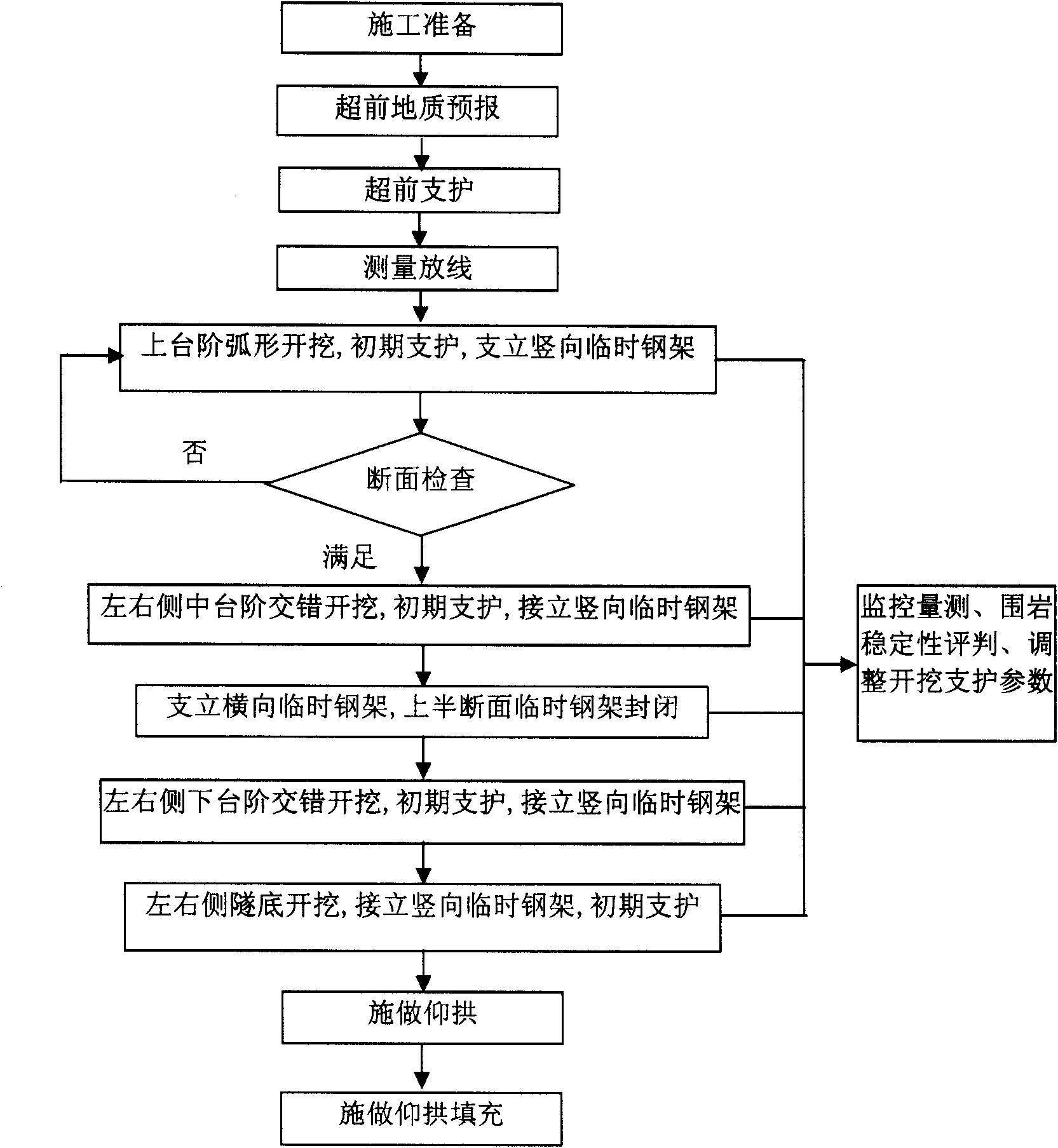

Method used

Image

Examples

Embodiment Construction

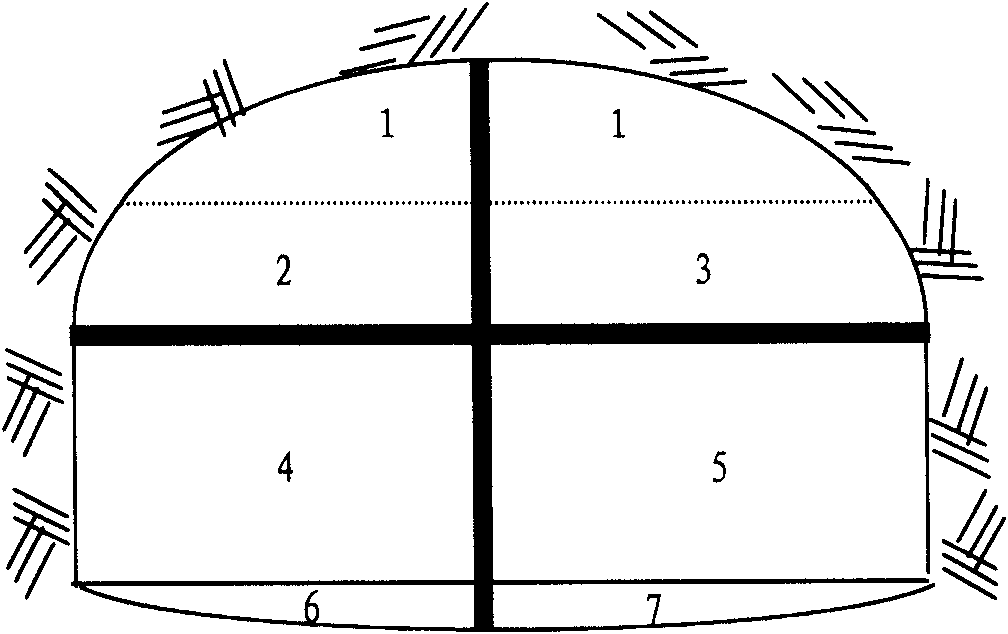

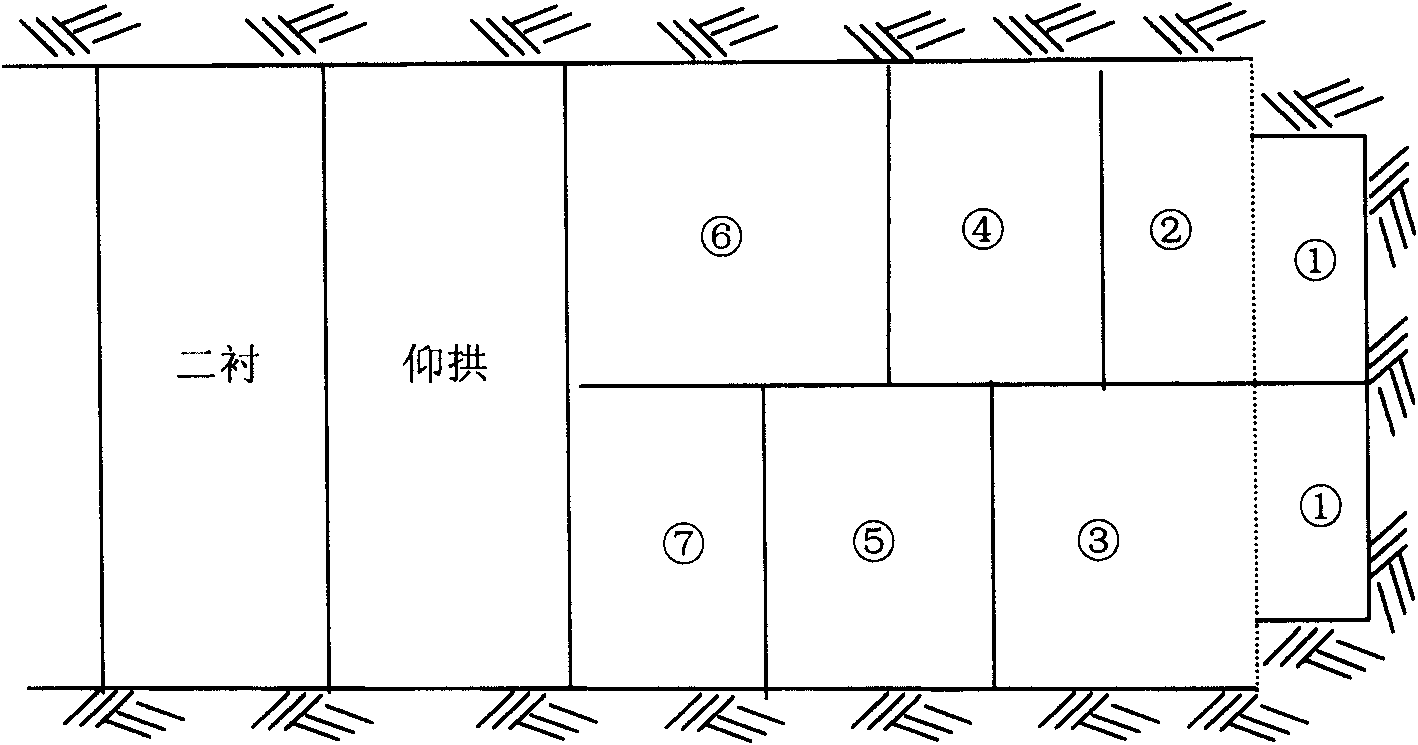

[0009] Step 1: Excavation and support for the upper steps 1. Constructing ① part of the advanced small conduit; 2① part of circular mechanical excavation and manual trimming; ① part of the tunnel surface sprayed concrete to seal; Net; 5① install initial supporting steel frame, install ① system anchor rod and lock foot anchor pipe; 6① spray initial support; 7 excavate ① part core soil, temporary vertical steel frame support;

[0010] Step 2: Excavation and support of middle steps 1②, ③ parts mechanically staggered excavation, manual trimming; 2② parts, ③ parts are sprayed with concrete to seal; 3② parts, ③ parts are initially sprayed with 4cm thick concrete; 4② parts, ③ parts Hang reinforcement mesh at the part; 5② and ③ install initial support steel frame, install ② and ③ system anchor rod and lock foot anchor pipe; 6② and ③ spray initial support; 7 excavate ② and ③ The core soil between the ③ parts is supported by the vertical steel frame of the temporary middle step; 8 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com