Screwdriver ratchet device with built-in ratchet and application thereof

A ratchet device and screwdriver technology, which is applied to screwdrivers, wrenches, wrenches, etc., can solve the problems of complex ratchet mechanism structure and high production cost, and achieve the effects of long service life, simplified structure and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

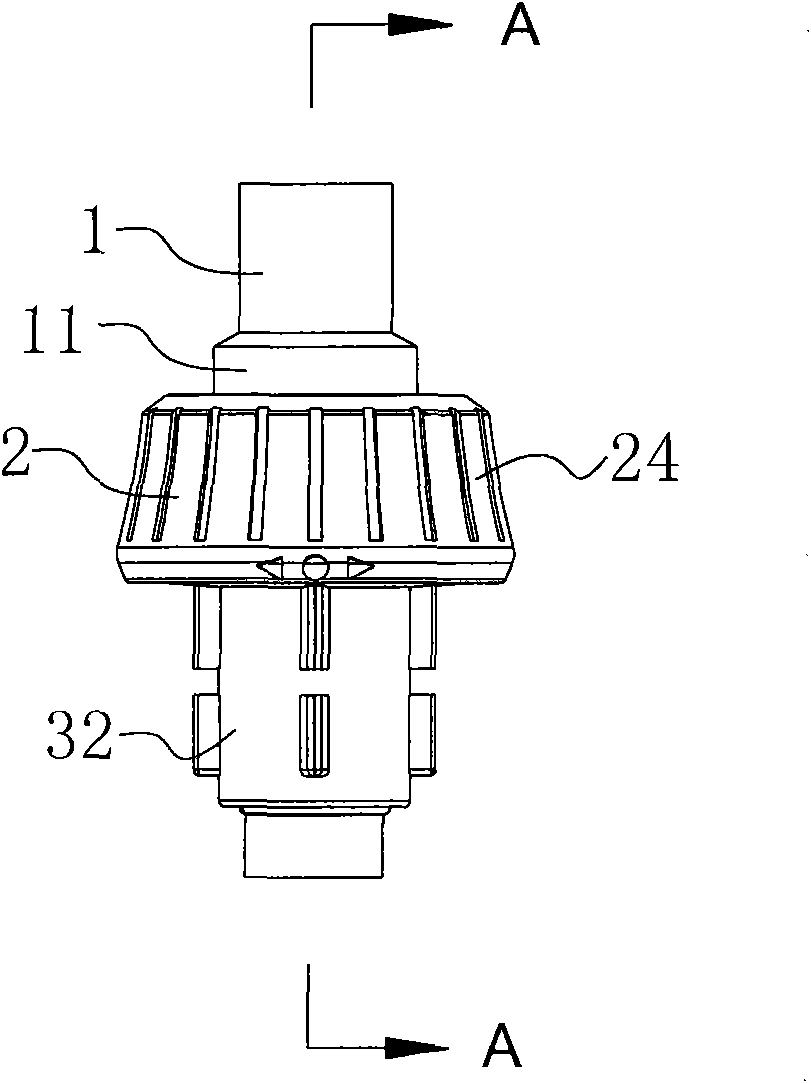

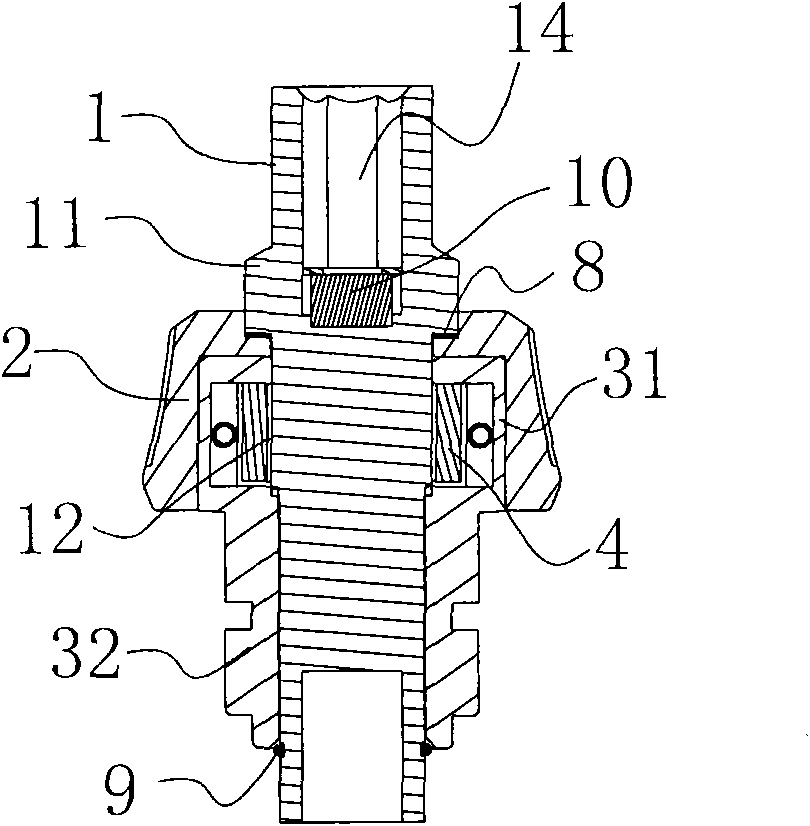

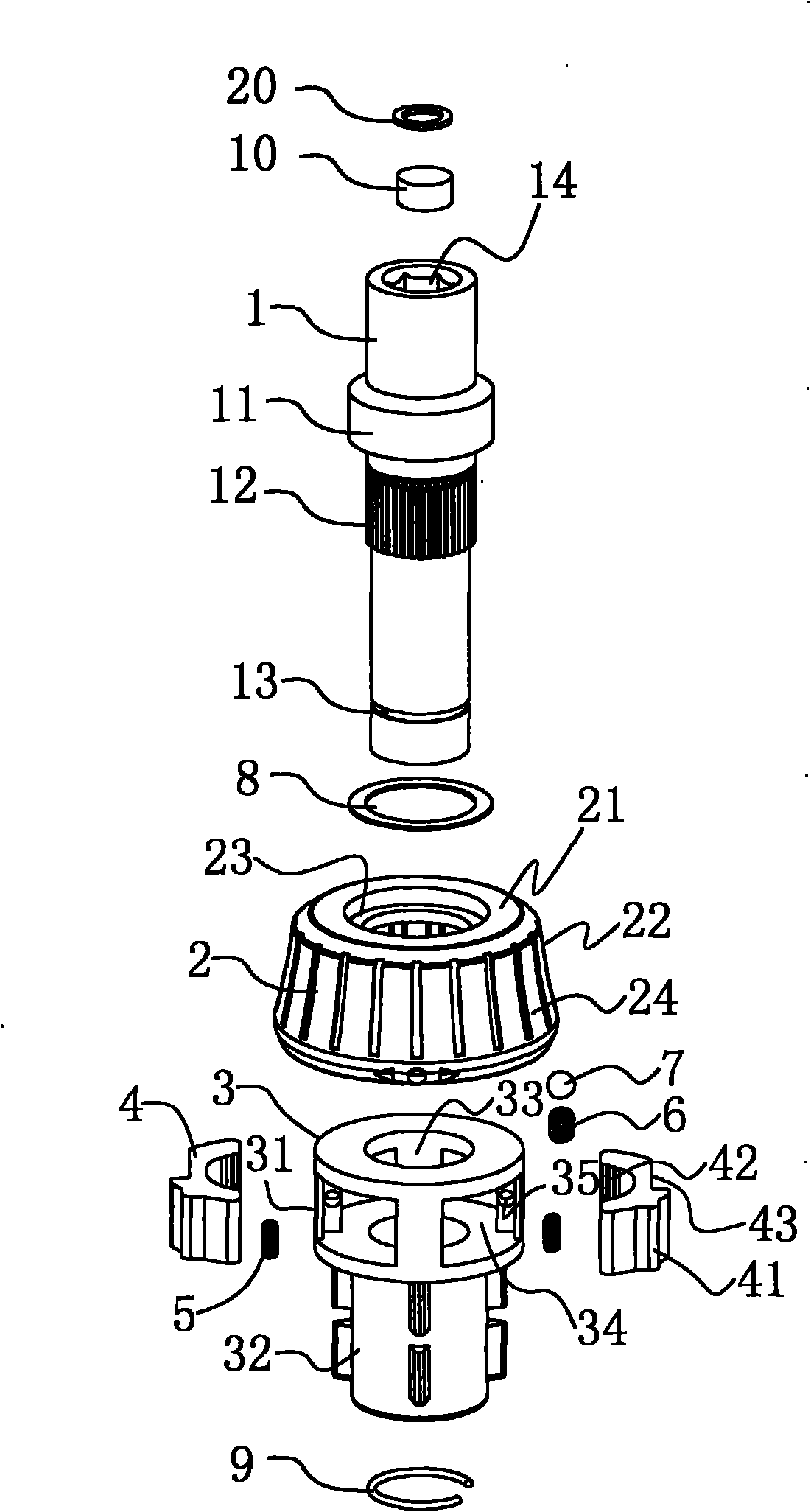

[0026] Such as figure 1 , figure 2 , image 3 The shown screwdriver ratchet device with a built-in ratchet includes a ratchet seat 3 , a ratchet shaft 1 , an outer collar 2 and two ratchets 4 . Such as Figure 4 , Figure 5 As shown, the pawl seat 3 is composed of an annular body 31 and a connecting portion 32 for connecting the handle body of the screwdriver. The annular body 31 is provided with a central shaft hole 33, and pawl installation ports are respectively provided on both sides of the central shaft hole 33. 34. The two pawls 4 are respectively arranged in the pawl installation opening 34. Such as image 3 As shown, the ratchet shaft 1 is installed in the central shaft hole 33, the upper part of the ratchet shaft 1 is provided with a screwdriver bit mounting hole 14, and a magnetic steel 10 is arranged in the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com