Dual-action composite water and air hybrid concentrating machine

A concentrator and air technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of high production cost, large ore loss, low production efficiency, etc., to improve the separation rate and quality of ore, reduce machine load, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

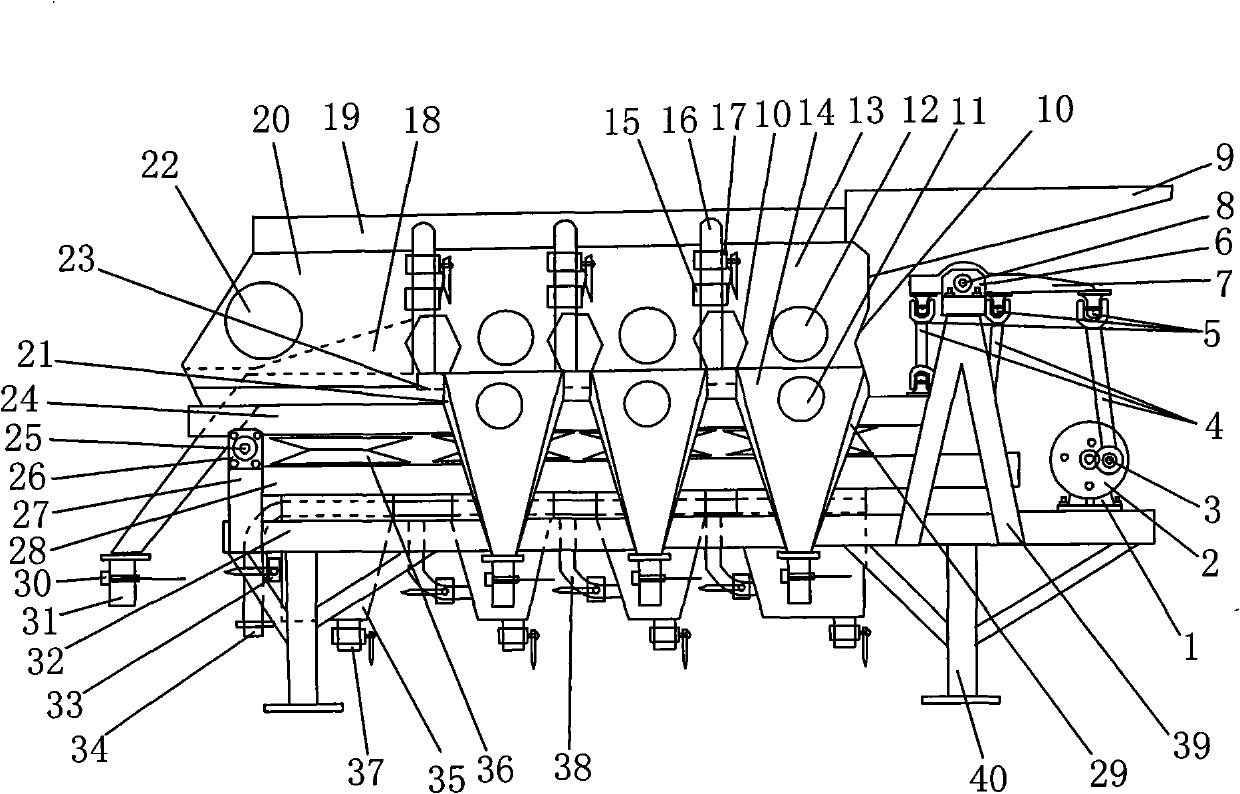

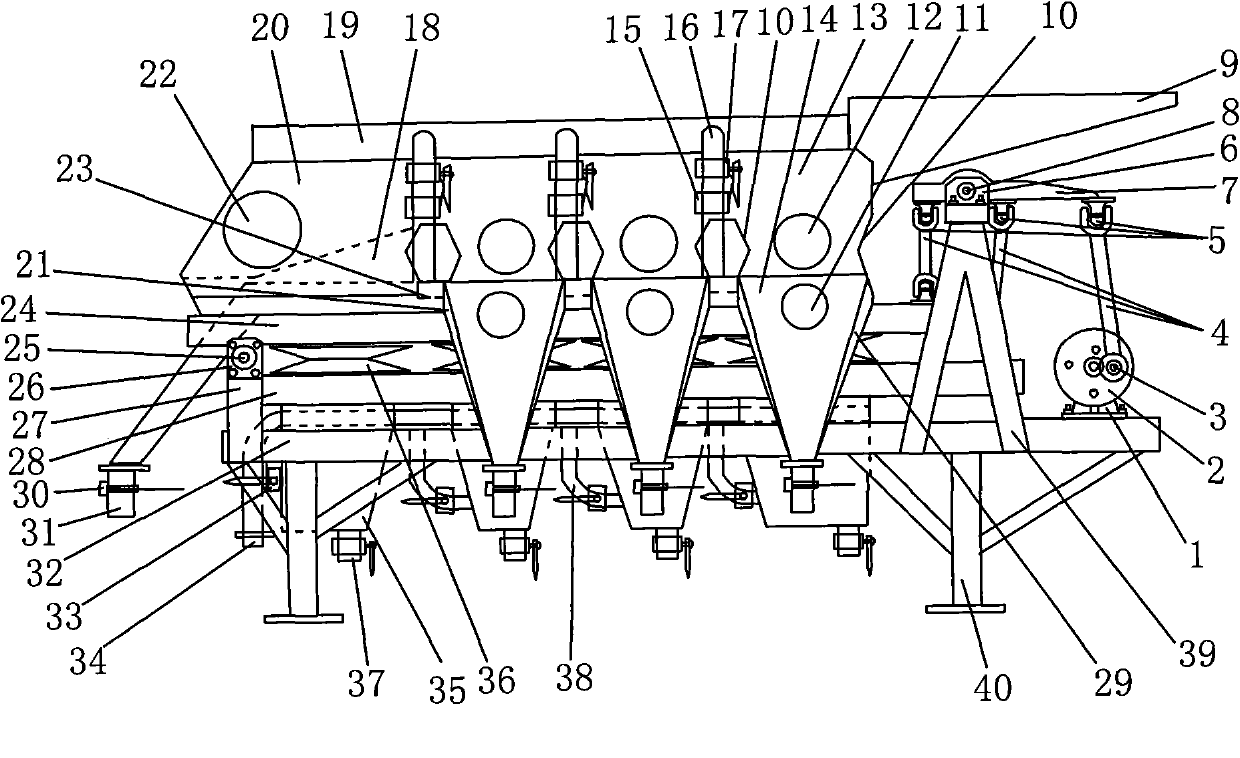

[0014] As shown in the figure, this double-action compound water and air mixed concentrator mainly includes rear axle lever assembly, upper frame combination, middle frame combination, lower frame combination and front axle assembly, upper frame combination, middle frame combination and lower frame The combinations are arranged sequentially from top to bottom. The rear axle lever assembly is simultaneously connected to one end of the upper frame combination, the middle frame combination and the lower frame combination, and the front axle assembly is located at the other end of the upper frame combination, the middle frame combination and the lower frame combination.

[0015] The upper shelf combination mainly includes the upper shelf 24, the ore feeding chute 9 and the water and air mixing and separation ore miscellaneous box 13. On one side of 13, water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com