Fixed plug-in pot opening with outer block

A plug-in spout technology, applied in the field of fixed plug-in spout with external stop, can solve problems such as low work efficiency, unsuitable for large-scale batch processing, easy to form false welding of contacts, etc., to ensure sufficiency and firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

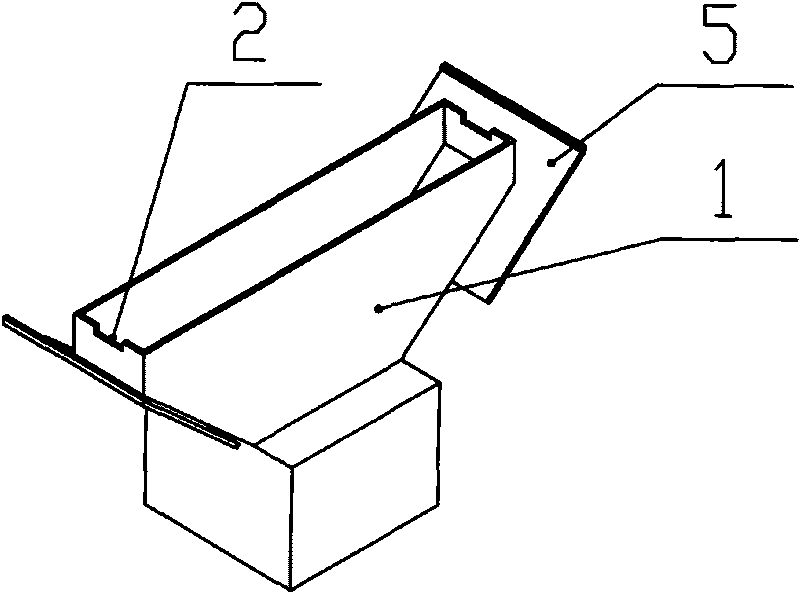

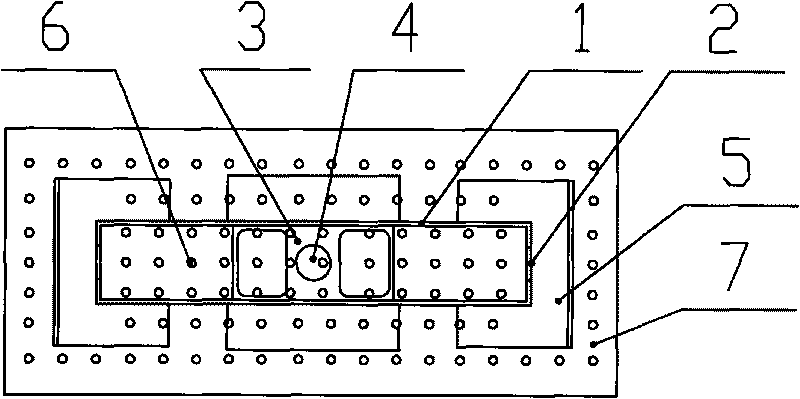

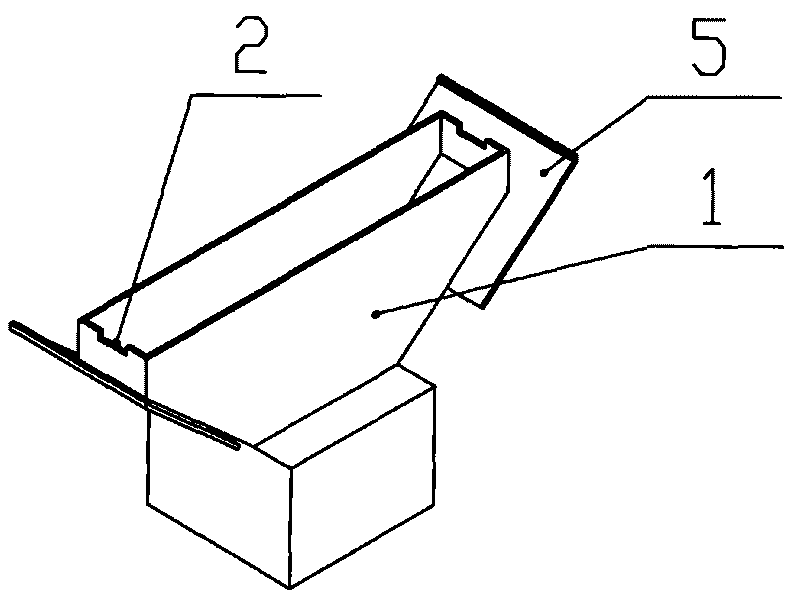

[0013] Such as figure 1 Shown is a fixed plug-in spout with an outer stop, the mouth of the spout is provided with a conical socket 1, and at least one overflowing tin opening 2 is provided on the edge of the conical socket 1, and the overflowing tin opening 2 It is a rectangular opening with a depth of 3-6mm. A fixing plate 3 is arranged on the inner wall of the mouth of the pot, a fixing hole 4 is opened on the fixing plate 3, and a baffle 5 is arranged on the outside of the overflow tin mouth

[0014] Such as figure 2 As shown, before welding, the spout and the PCBA board 7 are firmly connected through the fixing holes 4 on the fixing plate 3 through the fixing bolts. Depending on the distribution situation, usually the electronic components 6 on the PCBA board outside the tin overflow port 2 are relatively far away from the tin overflow port 2, and the flow is blocked by the baffle 5 so that the tin liquid flowing from the tin overflow port will not spread and overflow....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com