Double-opening spout for dodging chip element

A double-opening and pot-mouth technology, which is applied in the direction of assembling printed circuits with electric components, can solve the problems of low work efficiency, easy to form false soldering of contacts, and is not suitable for large-scale batch processing, so as to ensure sufficientness and firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

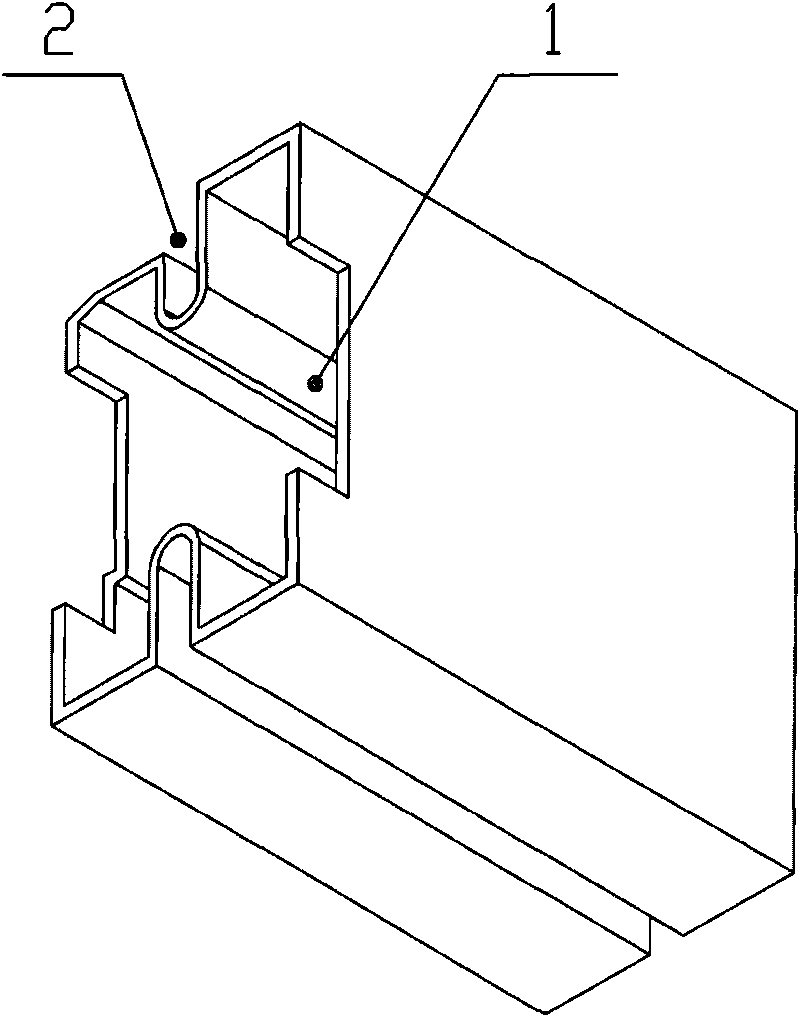

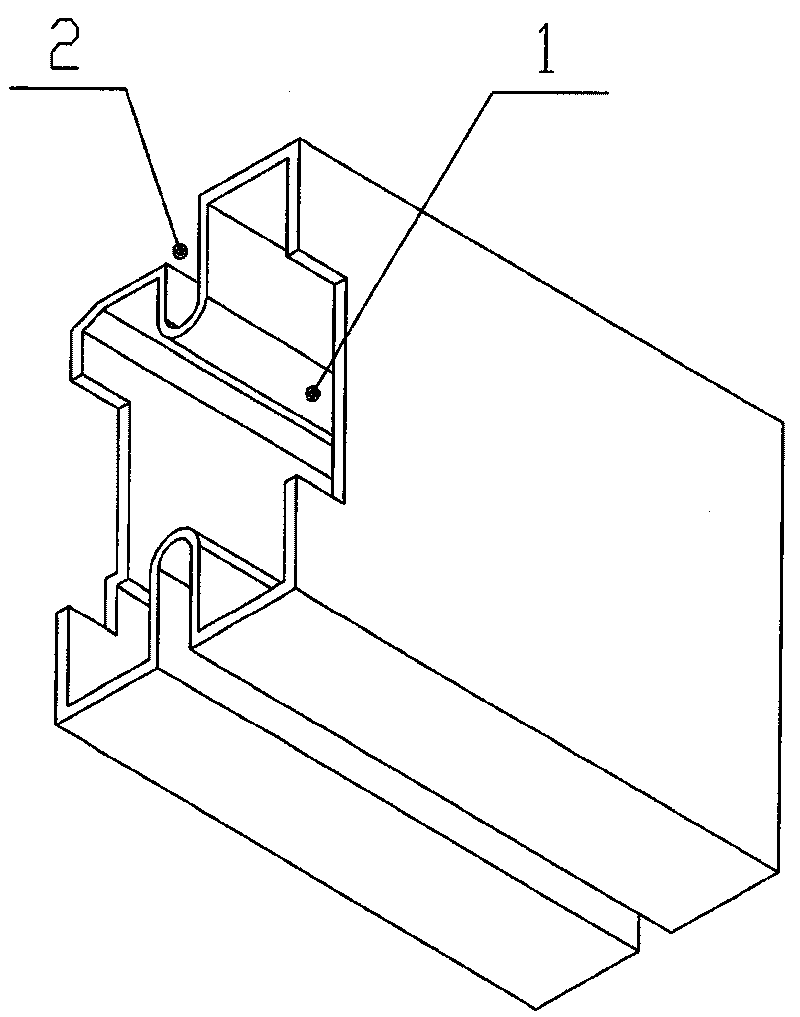

[0013] Such as figure 1 The shown chip element avoids a double-opening spout, the spout is rectangular in shape, a tin overflow port 1 is provided on one side edge of the rectangular side, and an inner groove 2 is provided on the other side of the rectangular side. The overflow tin opening 1 is a rectangular gap with a depth of 3-4mm, and the bottom of the inner groove 2 is a semicircular arc surface

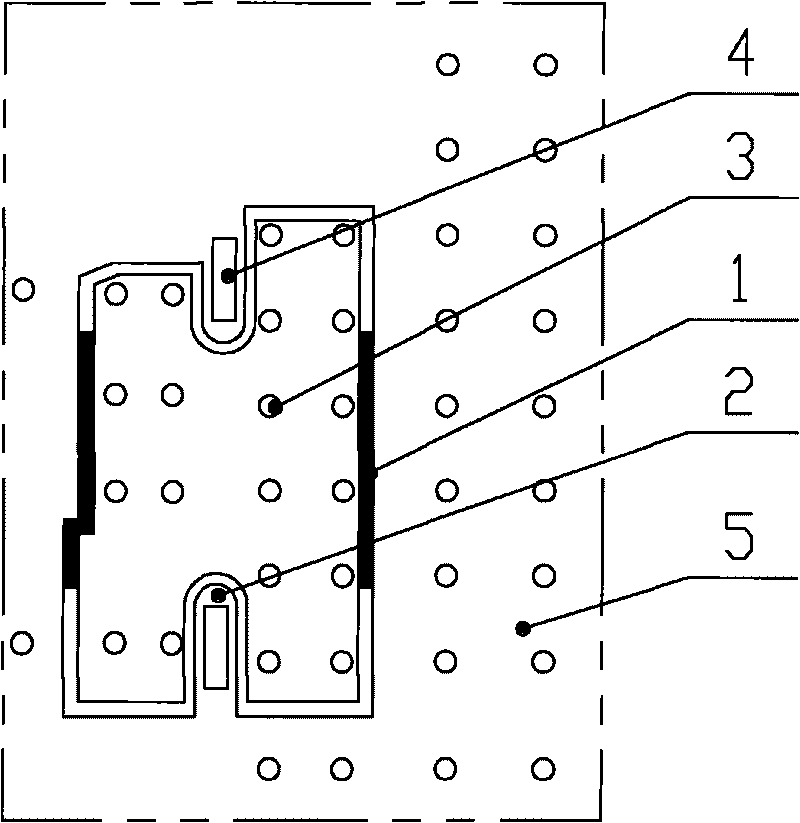

[0014] Such as figure 2 As shown, the spout of the present invention is mainly applied to the welding of electronic components 3 with short single-row lead wires, and the hatched part in the figure represents the tin overflow spout. On the PCBA board 5 , there are no other electronic components 3 outside the single row of leads or they are relatively far away, so that the tin liquid flowing out from the overflow tin opening 1 will not flow onto the electronic components 3 . The chip element is located in the inner groove 2.

[0015] When in use, place the PCBA board at a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com