Manufacturing process for main shaft of large water turbine

A manufacturing process and technology of hydraulic turbines, which are applied in the directions of shafts, mechanical equipment, hydropower generation, etc., can solve the problems of hydraulic turbine manufacturers unable to provide products to users in time, high cost, and long production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

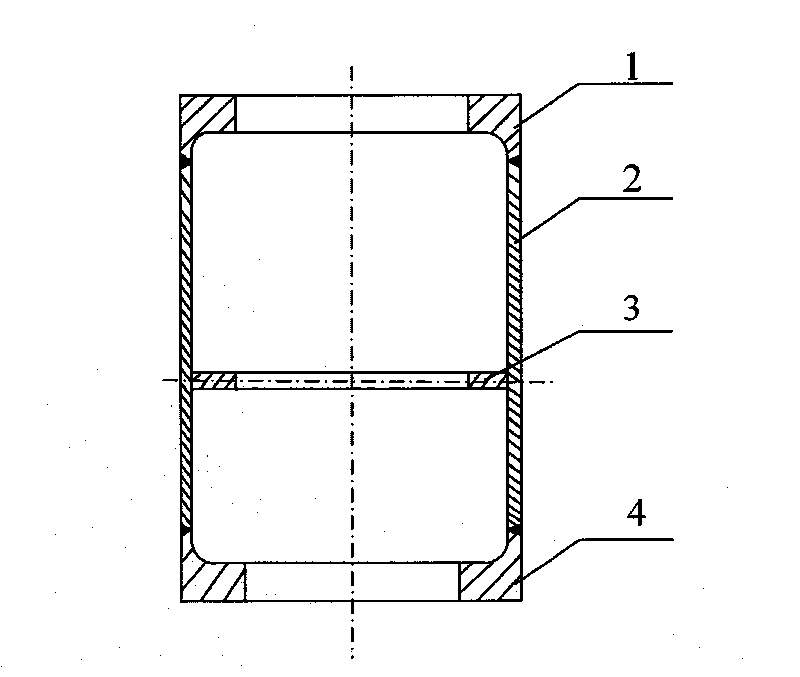

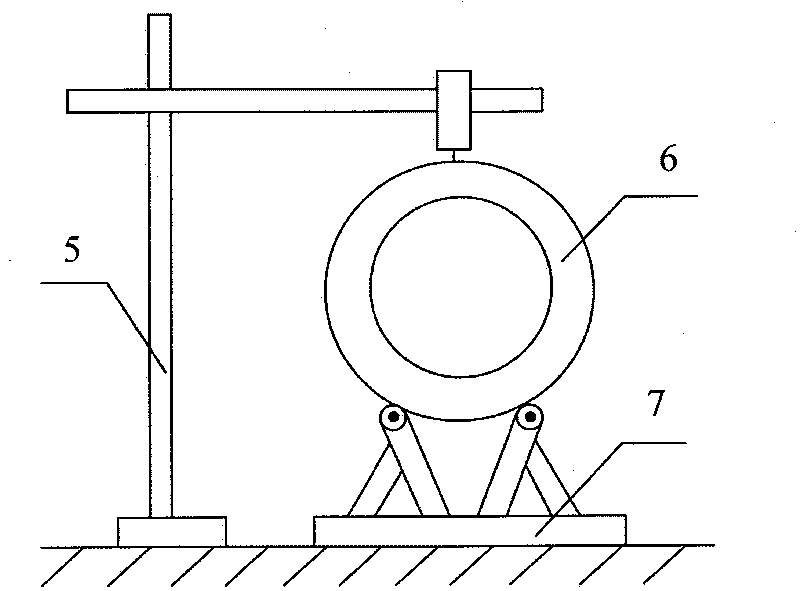

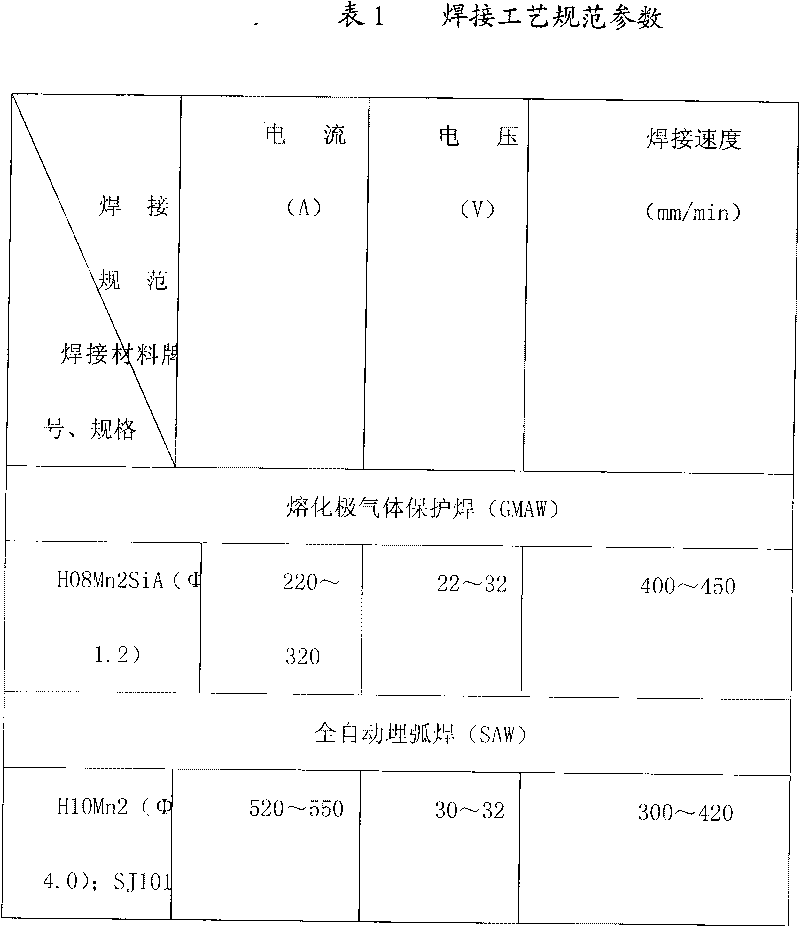

[0007] A manufacturing process for the main shaft of a large hydraulic turbine. The shaft body is divided into two sections in the length direction, and each section is divided into two parts. It is formed by cold pressing with a 3,000-ton hydraulic press. For thick steel plates with a thickness of more than 100mm, the steel plate is stress-relieved once before forming. Heat treatment, the steel plate blank used for the forming of the single-lobe shaft body has enough forming allowance, and the unilateral allowance is 350-400mm; after the single-lobe shaft body is formed, the forming allowance is cut off, and the two-lobed cylinder is welded into one section The shaft body, the longitudinal weld of the shaft body adopts submerged arc welding; after welding, an intermediate stress relief heat treatment is performed on the single-section shaft body. The inner and outer circles are roughly machined; the welding groove between the two shaft bodies is processed, and the two shaft bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com