Gear chamber cover of crank round sliding block internal-combustion engine, engine block assembly and internal-combustion engine thereof

A technology of crank circular slider and gear chamber cover, which is applied in the direction of machine/engine, engine cooling, and lubricating pump pressure lubrication. Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

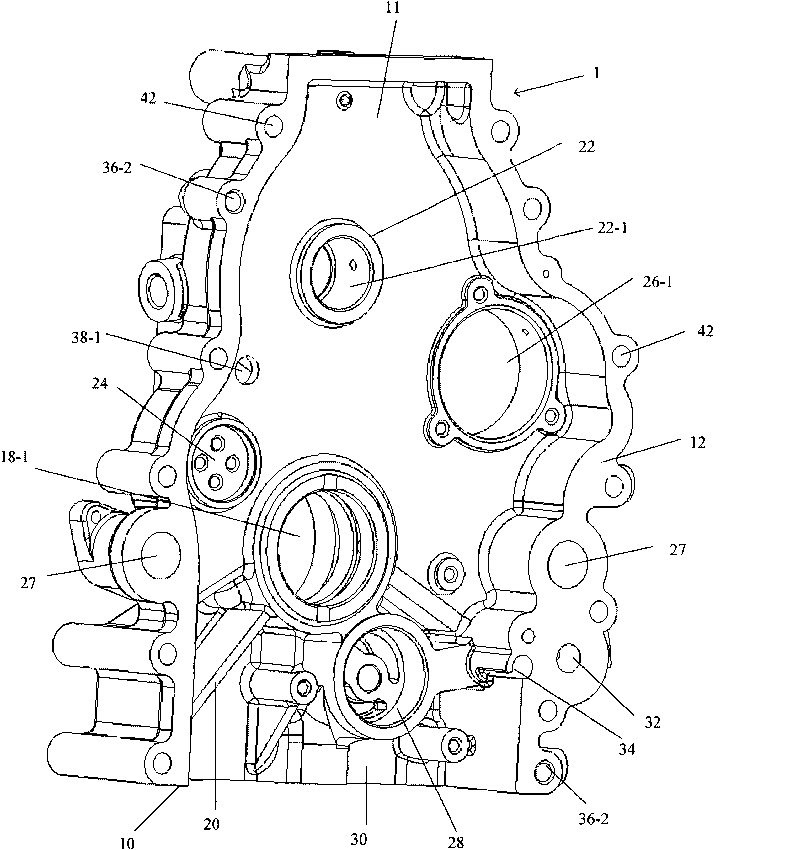

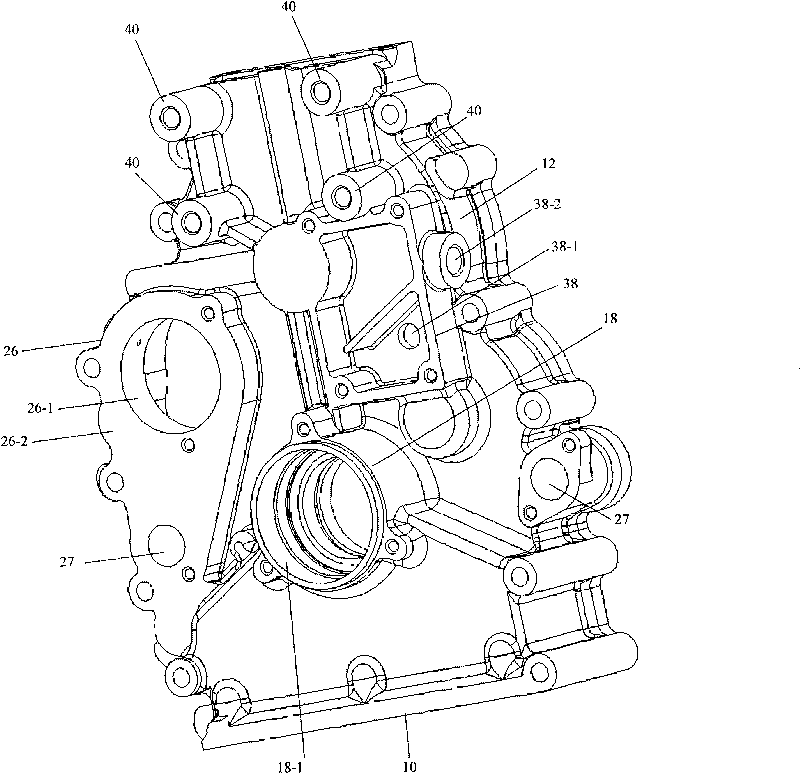

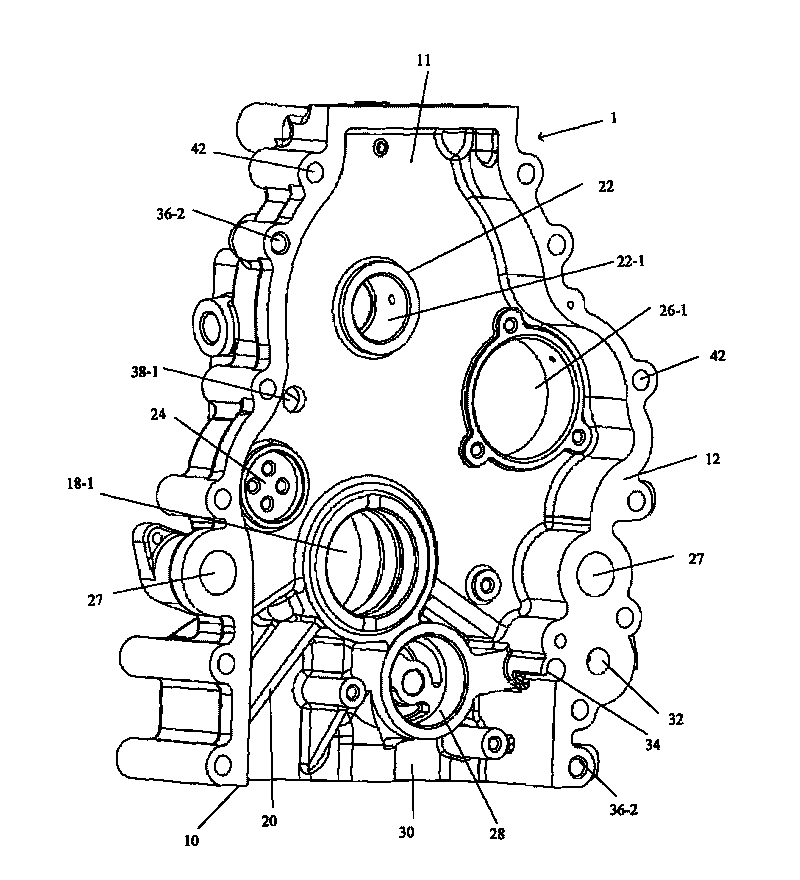

[0033] In the crank-slider internal combustion engine, the crank-slider motion conversion mechanism is used to replace the crank-connecting rod structure in the traditional internal combustion engine, so that the body of the crank-slider internal combustion engine is also changed from the traditional internal combustion engine. For example, since the balance counterweight of the crank-slider internal combustion engine is arranged outside the crankcase, and the reciprocating inertial force of the piston needs to be balanced by the balance counterweight, it is necessary to provide support for the gear shaft or the pulley shaft on which the counterweight is provided. And this support cannot be arranged on the body, otherwise makes the body too complicated. The invention provides a gear chamber cover of a crank-slider internal-combustion engine, at least a bearing seat for supporting a gear shaft or a pulley shaft provided with a counterweight is arranged on the gear chamber cover,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com