Method for producing aromatic hydrocarbon by high-olefin light hydrocarbon

A technology of olefin content and light hydrocarbons, applied in chemical instruments and methods, chemical recovery, hydrocarbons, etc., can solve the problems of fast catalyst deactivation, high probability of coking, short one-way cycle, etc. The effect of strong coking ability and fewer regeneration times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

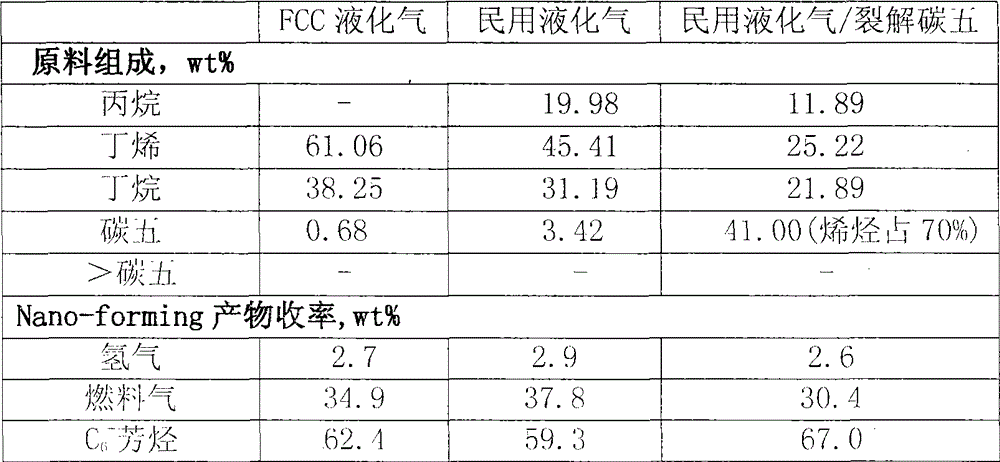

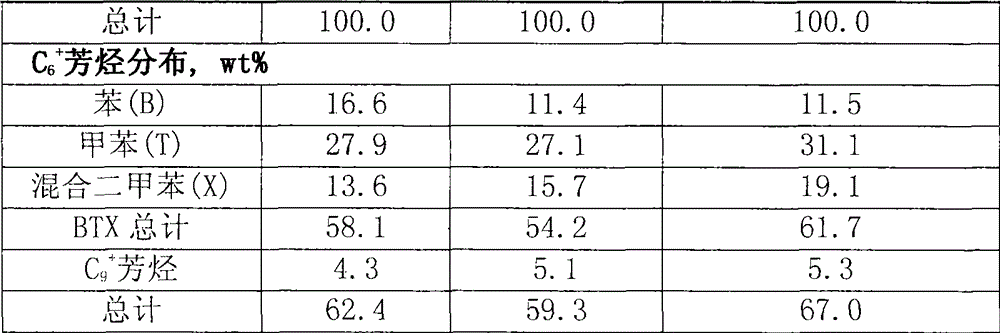

[0024] Embodiment: take carbon four, carbon five as example

[0025] The process steps are: the liquefied petroleum gas pretreated by impurities, cracked carbon five or the mixed raw materials of the two are gasified at 100-109°C in the high-efficiency anti-coking feed evaporator, then enter the composite heating furnace to raise the temperature to 450-570°C, and then Driven by the circulating return carrier gas, it enters the fixed-bed double reactor from top to bottom, and carries out aromatization under the action of special DLP-1 catalyst (produced by Shandong Qiwangda Group Haizhong Chemical Technology Co., Ltd., available in the market) Chemical reaction, reaction temperature 500°C-600°C, pressure 0-0.4MPa, space velocity 0.4-0.8h -1 . Most of the raw materials are converted into aromatic components such as benzene, toluene, and xylene, and at the same time, olefin-rich dry gases such as hydrogen, methane, ethylene, propane, and propylene are generated, and the yield of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com