Crane beam frame construction method

A construction method and crane beam technology, applied in the directions of load hanging components, transportation and packaging, support structures, etc., can solve the problems of low safety and low working efficiency at high altitudes, and achieve good results and reduce the risk of falling objects. possible, the effect of promoting construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

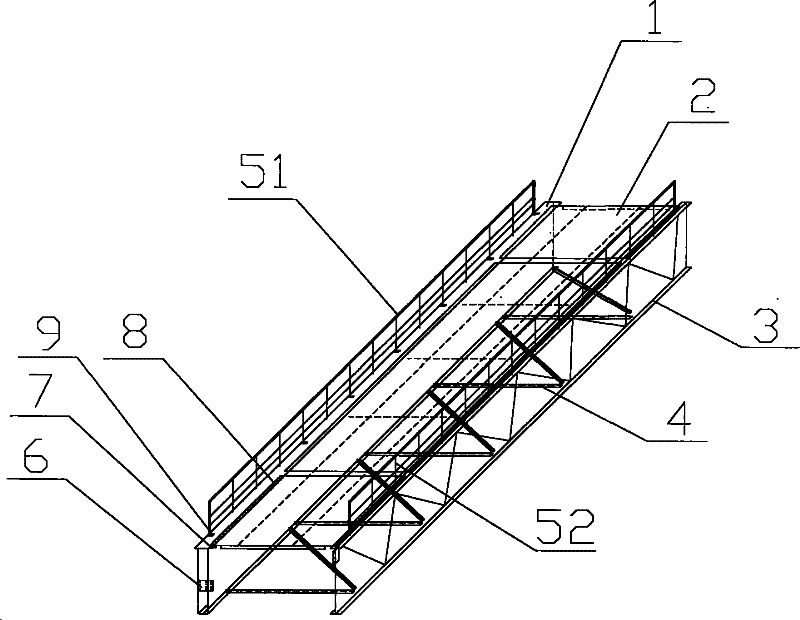

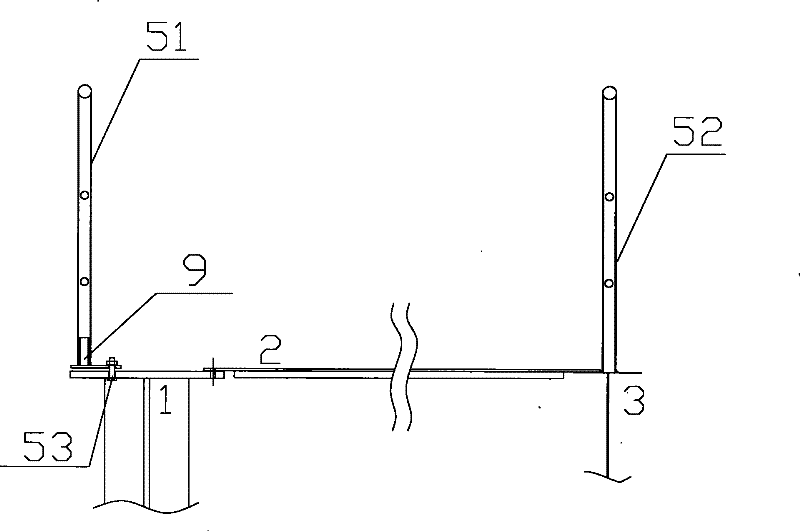

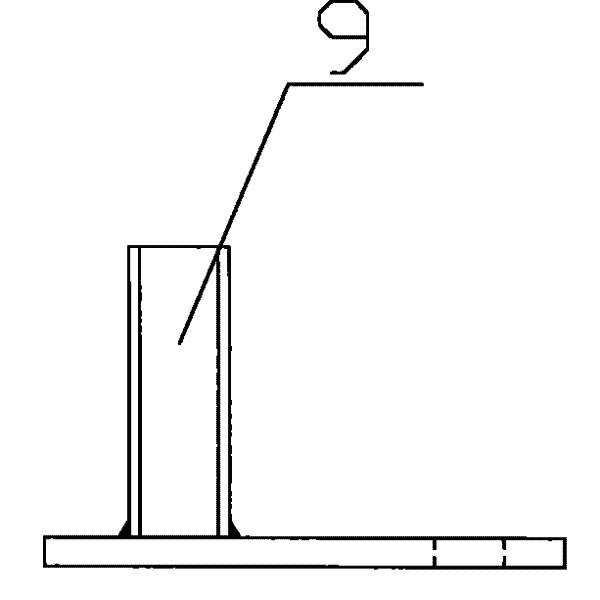

[0017] Now it is necessary to carry out the construction of the crane beam frame in a cold rolling workshop. The whole construction is divided into three steps: ground assembly, overall hoisting, and the use of formal railings. The crane beam frame consists of crane beam 1, brake plate 2, auxiliary truss 3, and horizontal support frame 4. Temporary railings 51, formal railings 52, railing bolts 53, connecting plates 6, hinge plates 7, brake plate bolts 8 and connecting members 9, such as figure 1 and figure 2 As shown, the crane beam 1 and the auxiliary truss 3 are arranged parallel to each other, the upper part of the crane beam 1 is fixedly connected with the brake plate 2 through the brake plate bolt 8, and the upper part of the auxiliary truss 3 is fixedly connected with the brake plate 2 by welding. 1 and the lower part of the auxiliary truss 3 are fixedly connected through the horizontal support frame 4, and the cross section of the crane beam 1 is fixed with a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com