Automatic ceramic tile detector

A detection machine and detection mechanism technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficulty in maintaining the consistency and stability of tiles for a long time, the consumption of manpower, material resources and time, and the high cost of products. The effect of detection efficiency and accuracy, time saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

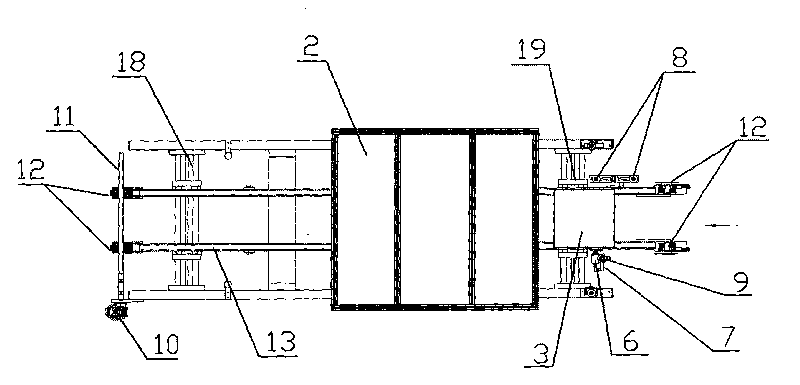

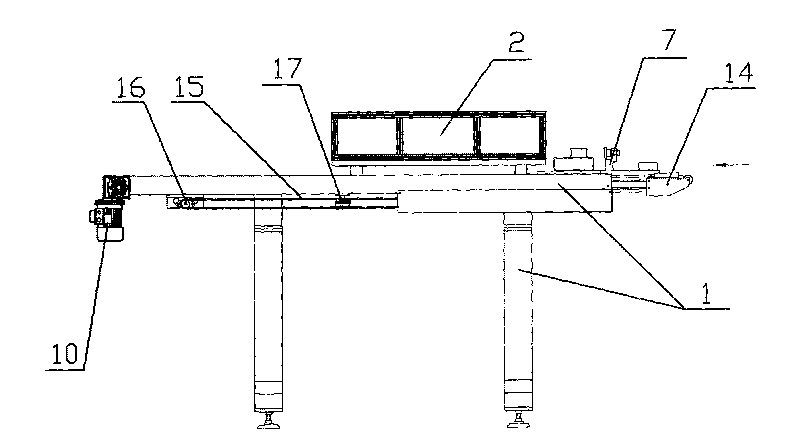

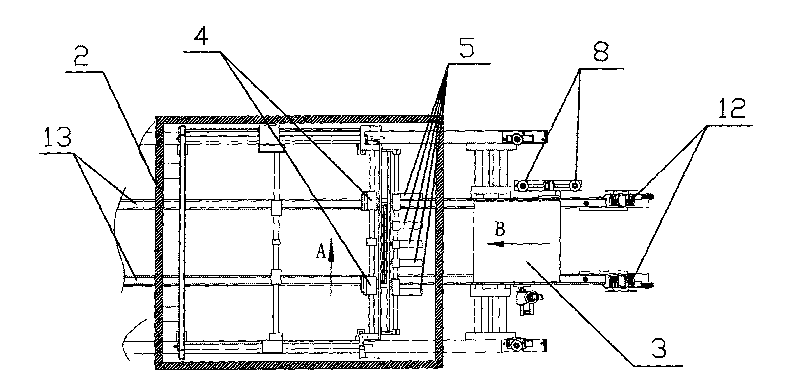

[0018] Such as Figure 1 to Figure 5 As shown, the present invention is a kind of ceramic tile automatic detection machine, a kind of ceramic tile automatic detection machine, comprises workbench 1, brick clamping mechanism, distance adjustment mechanism, brick feeding mechanism and detection mechanism, and brick feeding mechanism is arranged on workbench 1, The brick clamping mechanism is set at the head end of the brick feeding mechanism, the distance adjusting mechanism is set under the brick feeding structure, the detection mechanism is located above the brick feeding mechanism, and is fixedly connected with the workbench 1. The detection mechanism consists of the casing 2 and the The sensor consists of a sensor for detecting the external dimension of the ceramic tile 3 and a flatness sensor 5 for detecting the flatness of the ceramic tile 3. The external dimension sensor 4 is arranged at the upper and lower edges along the conveying direction of the ceramic tile 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com