Anode carbon block conveying equipment and conveying method

A technology for anode carbon block and conveying equipment, which is applied in the field of conveying equipment and conveying, can solve the problems of insufficient carbon block, affecting casting quality, affecting marshalling efficiency, etc., and achieves the effects of improving work efficiency, low equipment cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

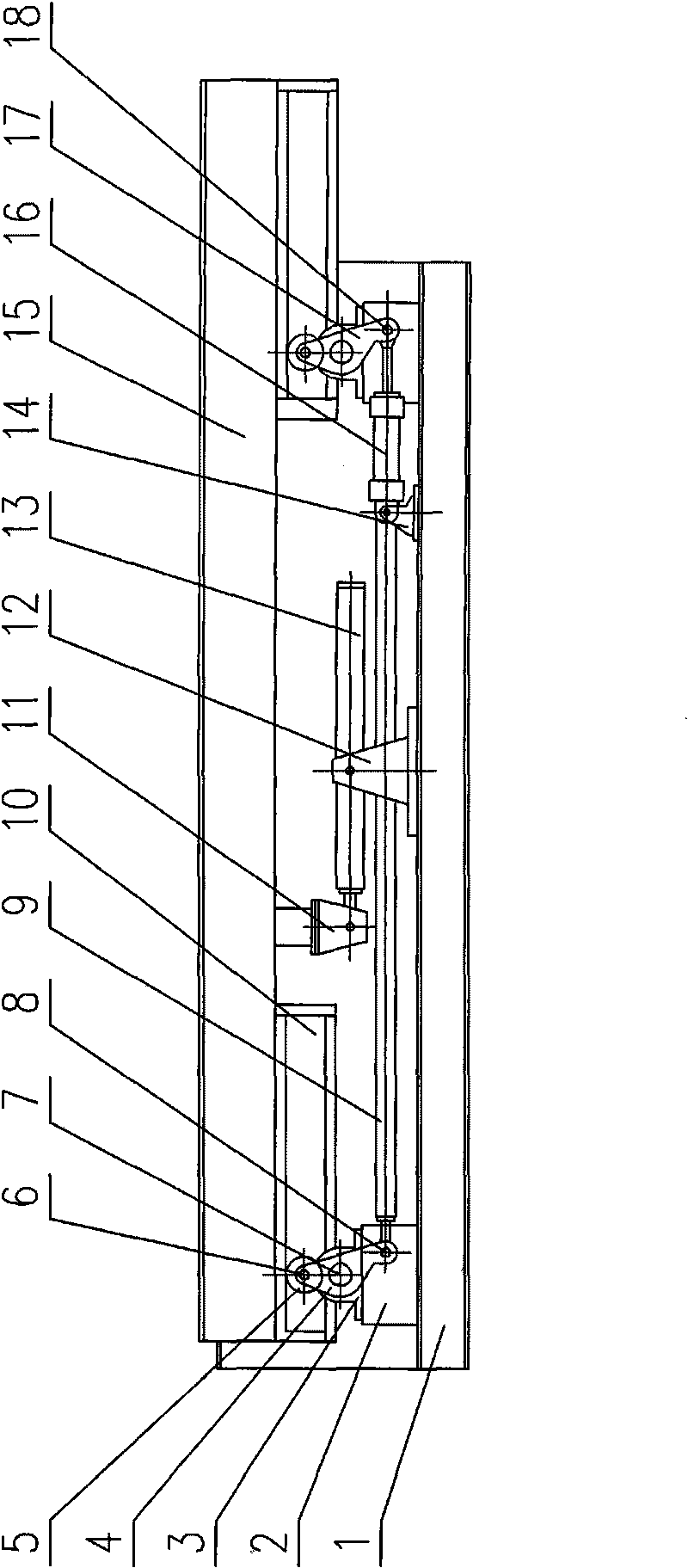

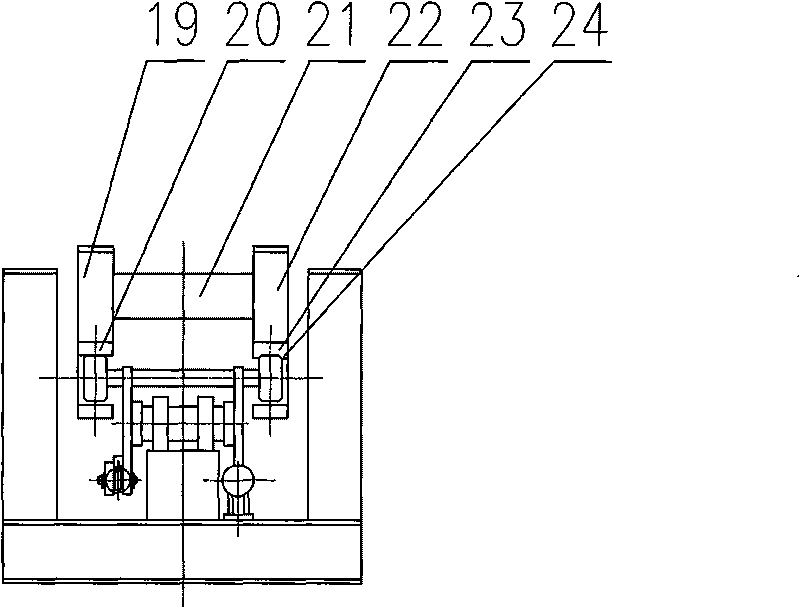

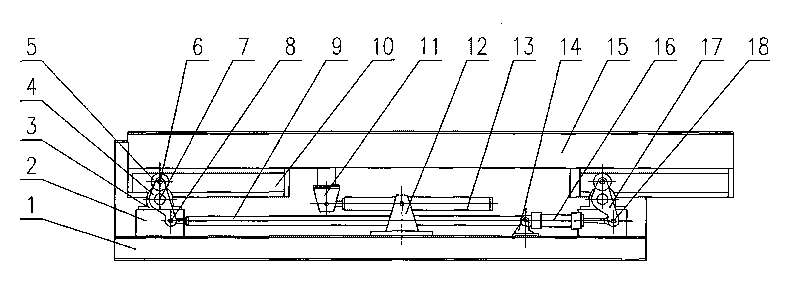

[0027] The anode carbon block conveying equipment of the present invention has a structure as follows: a lower bracket 12 is installed at the bottom of the fixed frame 1, a horizontally movable oil cylinder 13 is hinged with the lower bracket 12, one end of the horizontally moved oil cylinder 13 is hinged with the upper bracket 11, and the upper end of the upper bracket 11 is hinged with the upper bracket 11. Movable frame 15 connects, and the lower end of movable frame 15 is equipped with slideway 10, and roller is installed in slideway 10, is provided with the lifting control device for controlling movable frame 15 lifting between roller and movable frame 15.

[0028] like Figure 1-2 As shown, its detailed structure is as follows: the bottom of the fixed frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com