Loader specially for discharging coal

A loader, special technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of slow loading and unloading, not very flexible, low safety and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

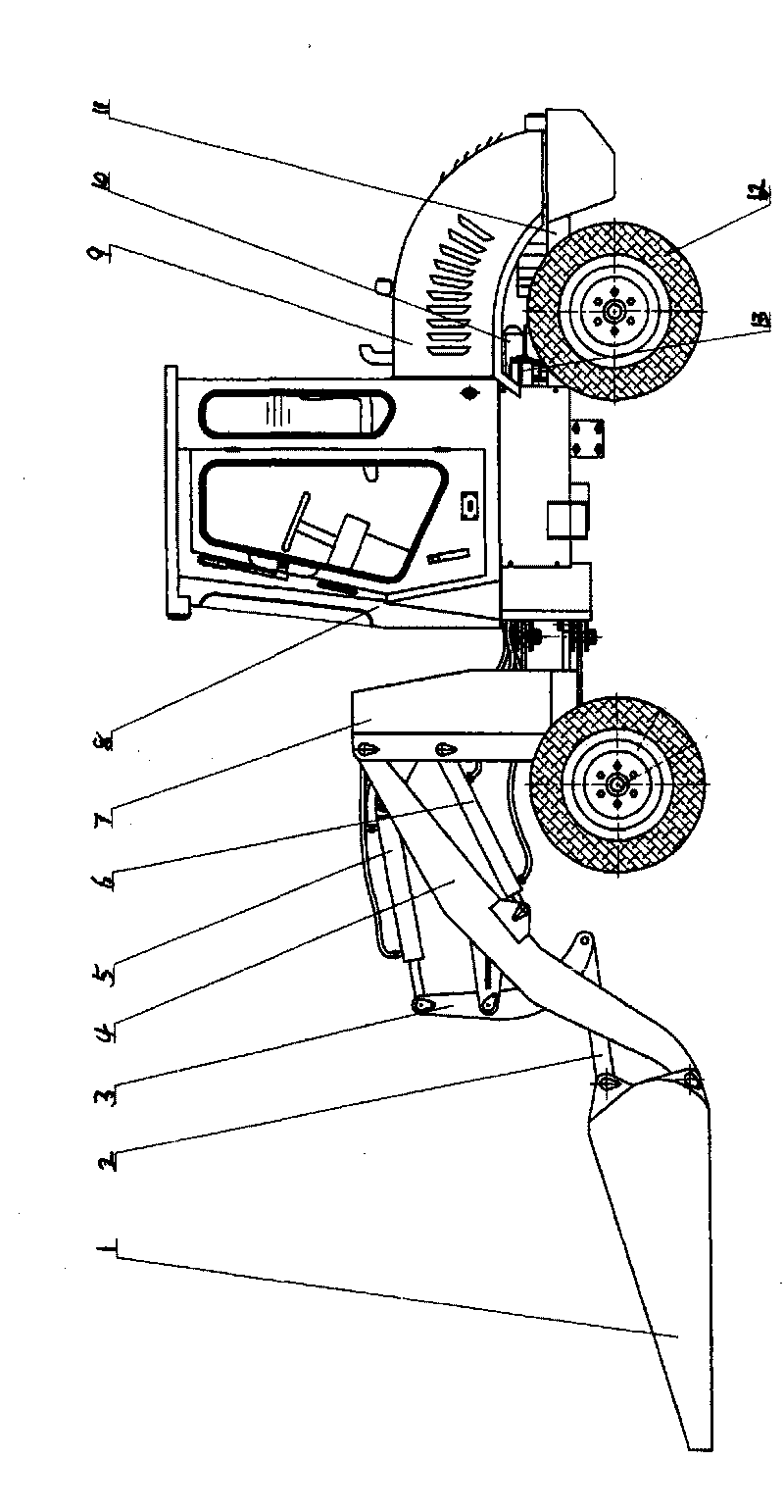

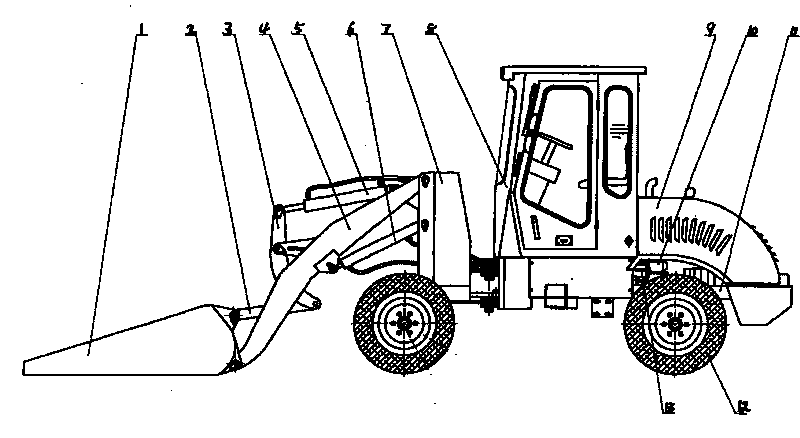

[0009] Referring to the figure, the present invention is mainly composed of a power source, an actuator and a working mechanism, and the working mechanism is composed of a bucket 1, a pull rod 2, a rocker arm 3, a boom 4, a rocker cylinder 5, a boom cylinder 6, and a cab 8 The executive mechanism is composed of multi-way reversing valve, oil pump, hydraulic cylinder, steering gear, gearbox, front and rear frames; On the rear frame 11, a multi-way reversing valve, an oil pump, a hydraulic cylinder, a steering gear, and a gearbox are also installed; Arm cylinder 5, boom cylinder 6, the front end of boom 3 is connected to the bottom shaft of bucket 1, the pull rod 2 is connected to the rear upper edge of bucket 1, and the rocker shaft, and the rocker is connected to the shaft of the rocker cylinder.

[0010] The working process is: the person in the cab converts the energy output by the power source into the power of each actuator by operating the actuators in the cab to complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com